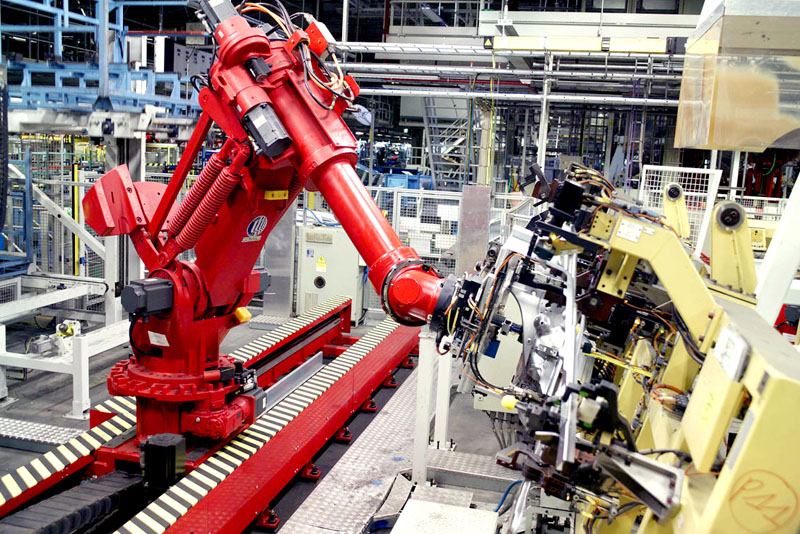

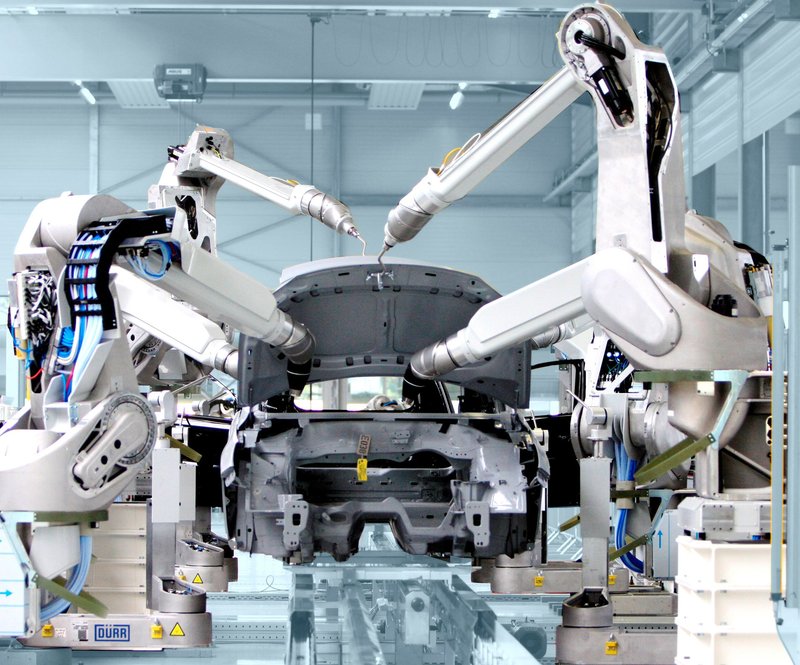

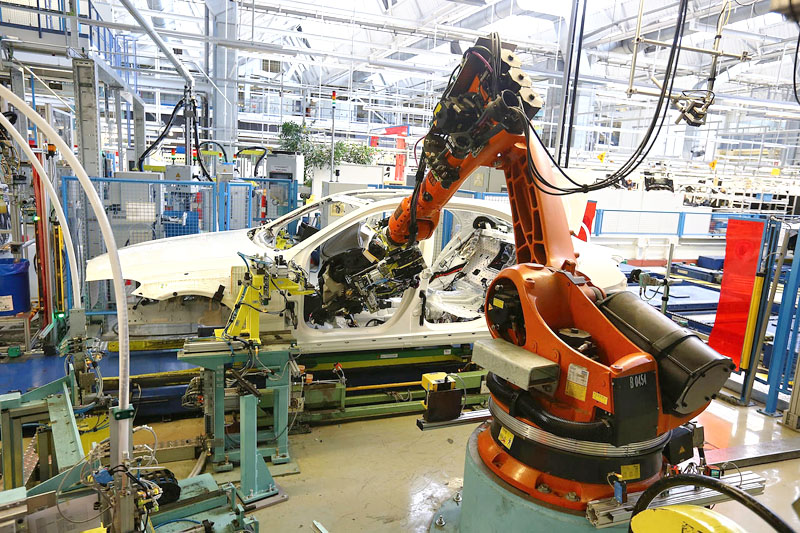

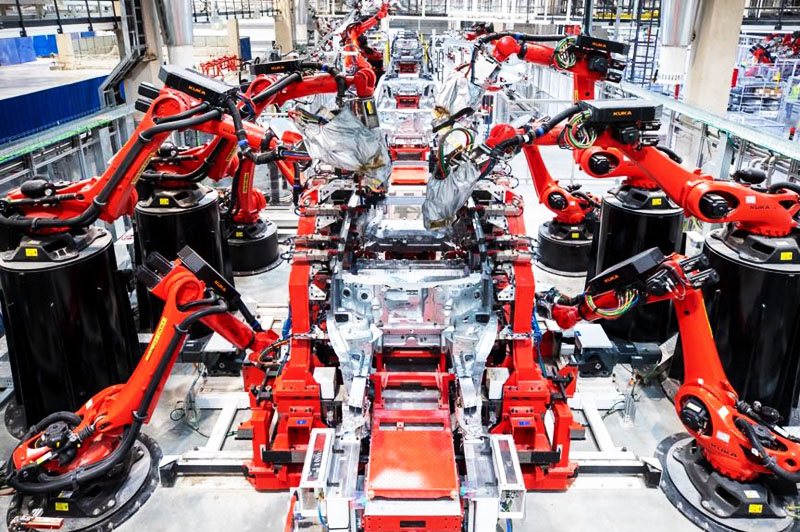

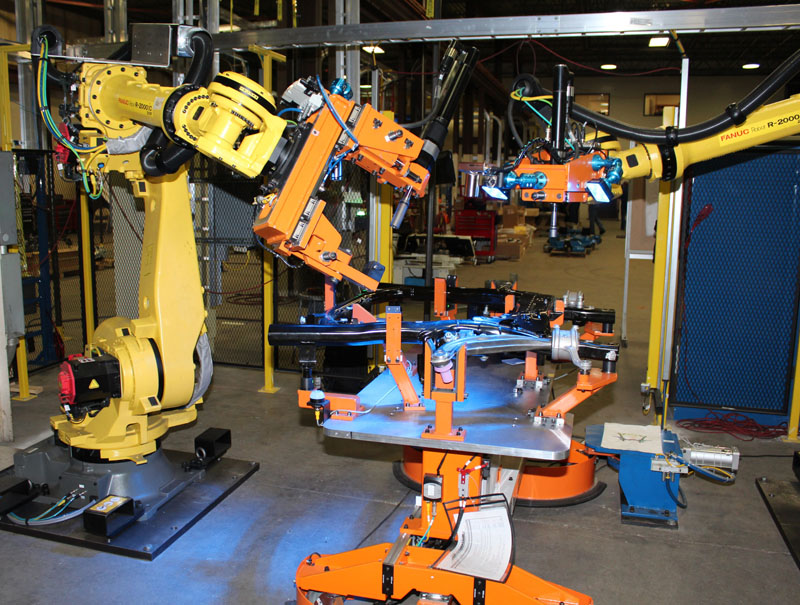

Robotic Car Production Line Solution

Robotic Car Production Line Solution:

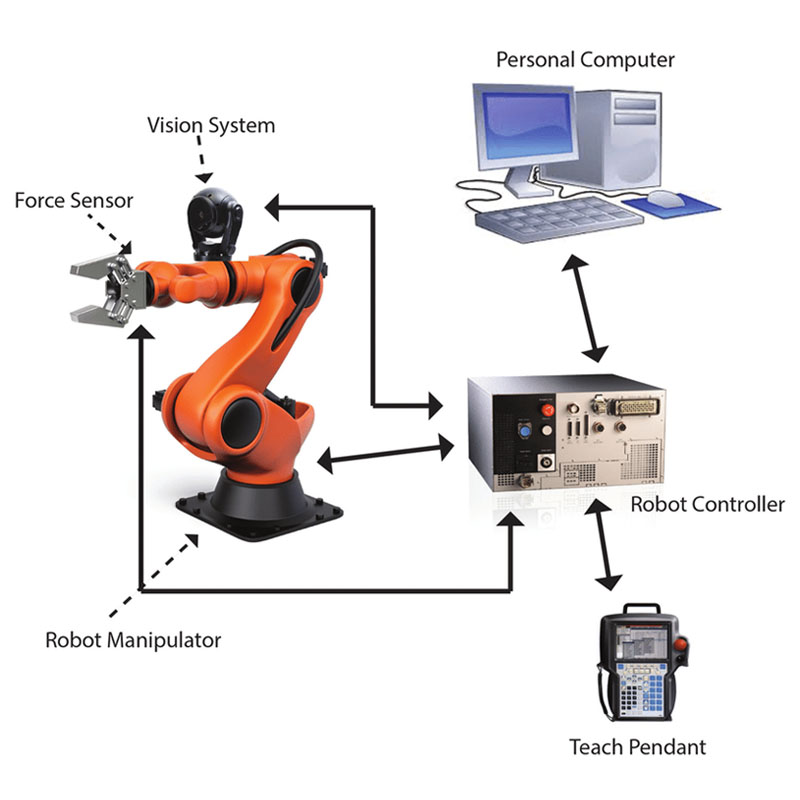

1,Increased Efficiency: Robots can work continuously without fatigue or breaks, leading to a higher production rate and reduced cycle times. This results in increased efficiency and faster car production.

2,Improved Precision: Robots are programmed to perform tasks with high accuracy and consistency. This leads to minimal errors and precise assembly of car components, ensuring better quality control and higher product standards.

3,Cost Savings: Robotic car production lines can help reduce labor costs by minimizing the need for human labor. Additionally, robots are more energy-efficient and require less maintenance compared to human workers, resulting in long-term cost savings for the manufacturing industry.

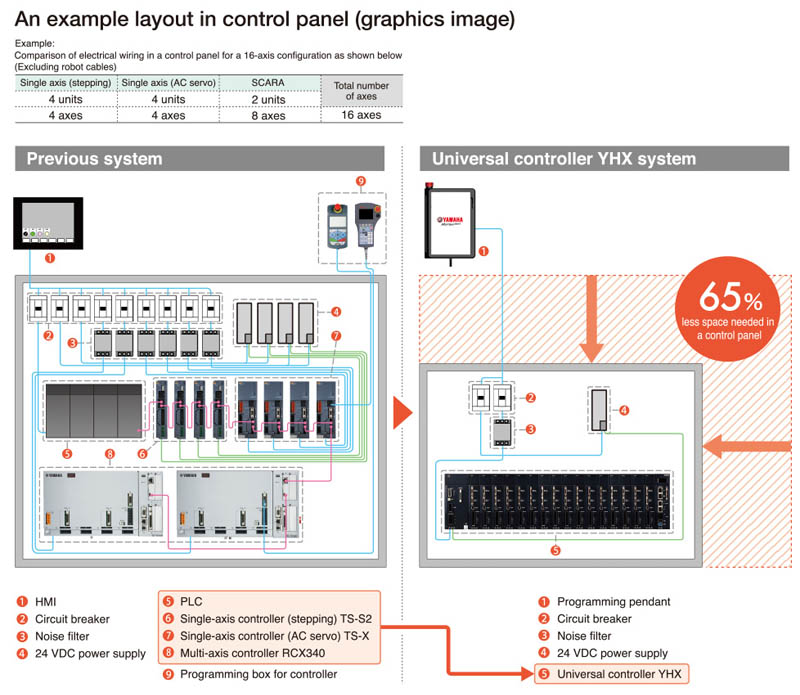

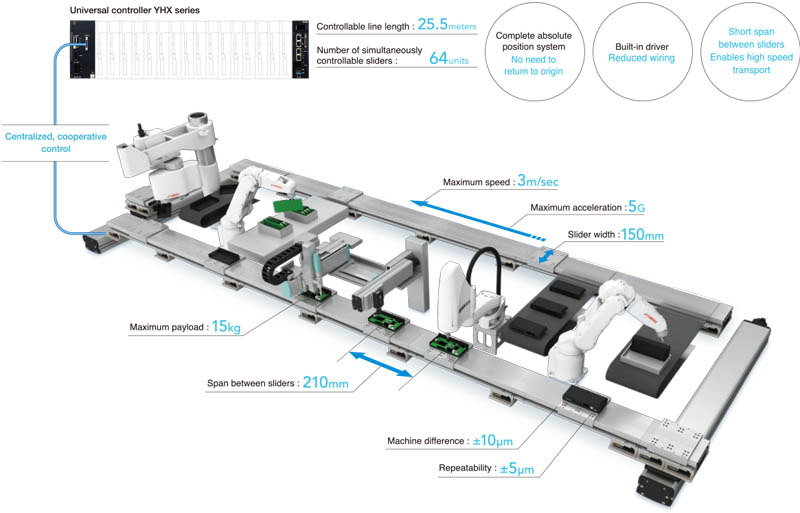

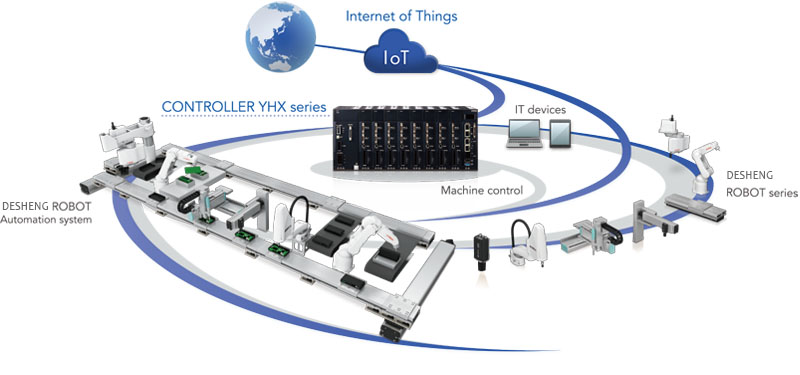

Please Contact Us For Detailed Technical Parameters.

Robotic Car Production Line Solution:

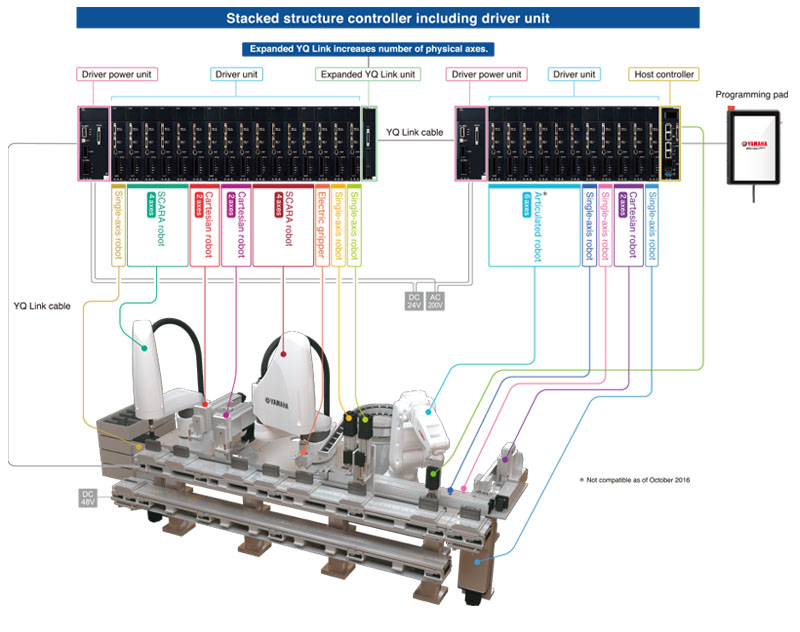

The use of a robotic car production line in the automotive industry has its advantages, but also some disadvantages. While robots offer precision and efficiency, they lack adaptability for complex and custom tasks. The initial investment and maintenance costs can be high, which may limit smaller manufacturers. Programming and reprogramming robots can also be time-consuming and requires specialized skills. Despite these drawbacks, the future of robotics in the automotive industry remains promising. Advancements in artificial intelligence and machine learning will lead to more intelligent and autonomous robots. Collaborative robots will work alongside humans, enhancing productivity and safety. With ongoing research and development, the automotive industry can harness the benefits of robotics while addressing the challenges they pose.