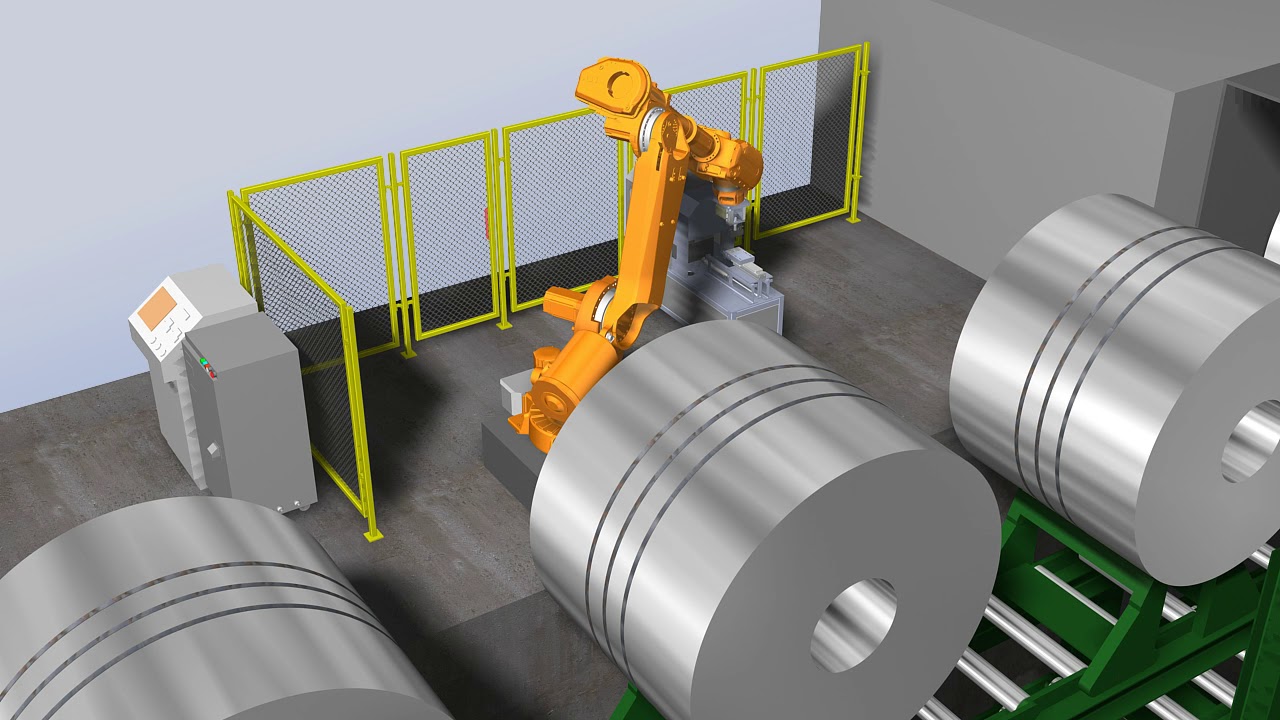

Robot In Steel Industry

Industrial Robotic Automation:

1,Increased productivity: Robots can perform tasks at a faster rate and with higher precision compared to human workers. This results in increased production rates and improved efficiency, ultimately leading to higher productivity levels.

2,Cost reduction: With robotic automation, manufacturers can reduce labor costs by replacing human workers with machines. Robots can work 24/7 without the need for breaks or vacations, leading to significant cost savings in the long run.

3,Improved quality and consistency: Robots are programmed to perform tasks with utmost accuracy and consistency, ensuring that products are manufactured to the highest standards. This eliminates human errors, resulting in improved product quality and customer satisfaction.

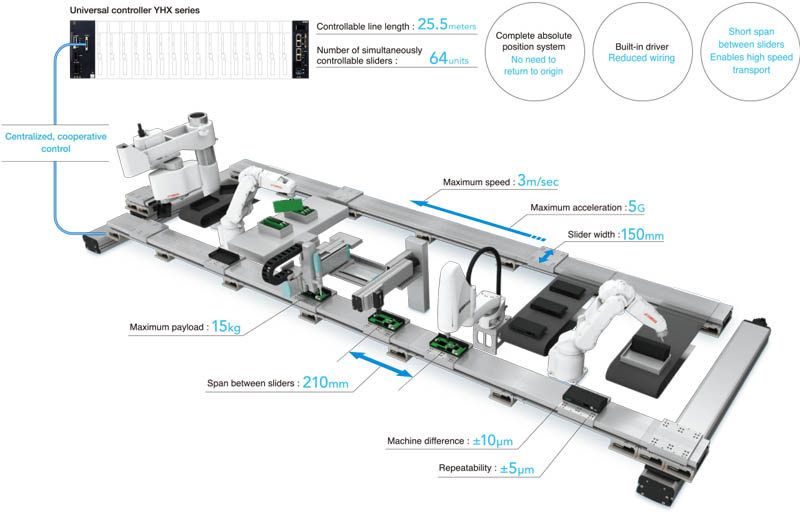

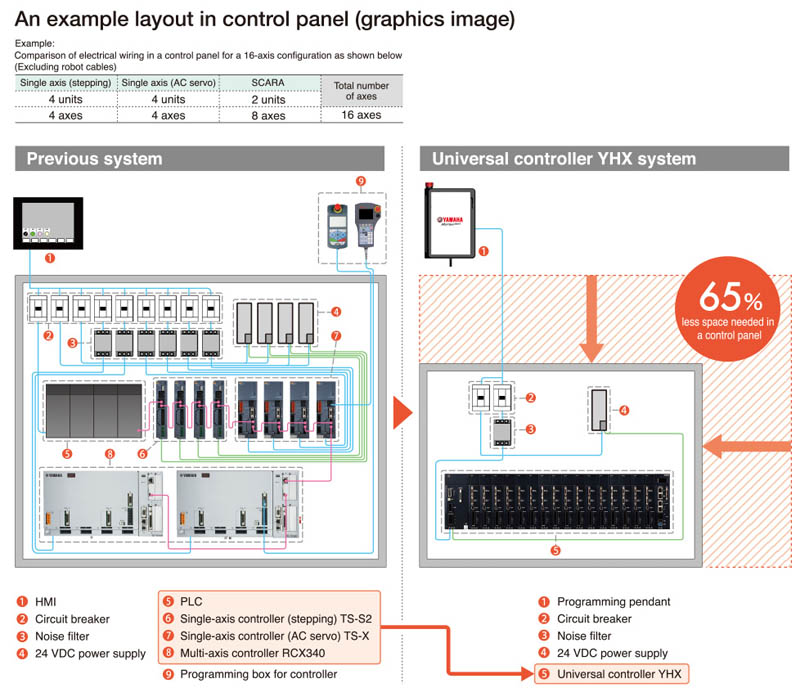

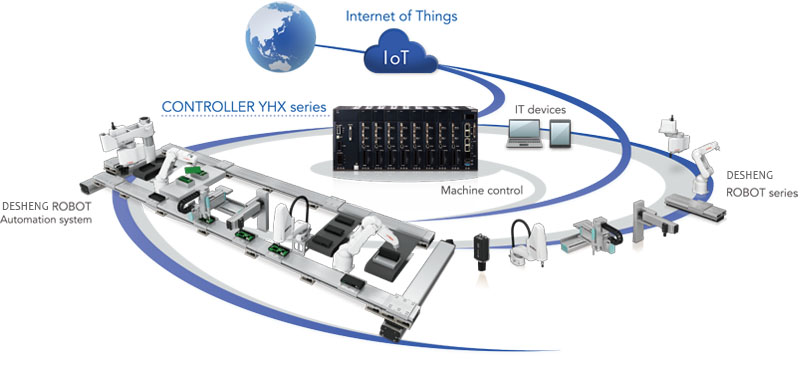

Please Contact Us For Detailed Technical Parameters.

Industrial Robotic Automation:

Robot in Steel Industry: The inclusion of robots in the steel industry has revolutionized the way work is carried out. With their precision and efficiency, robots have become an integral part of industrial operations. Whether it is welding, cutting, or handling heavy materials, industrial robots have proven to be highly effective.

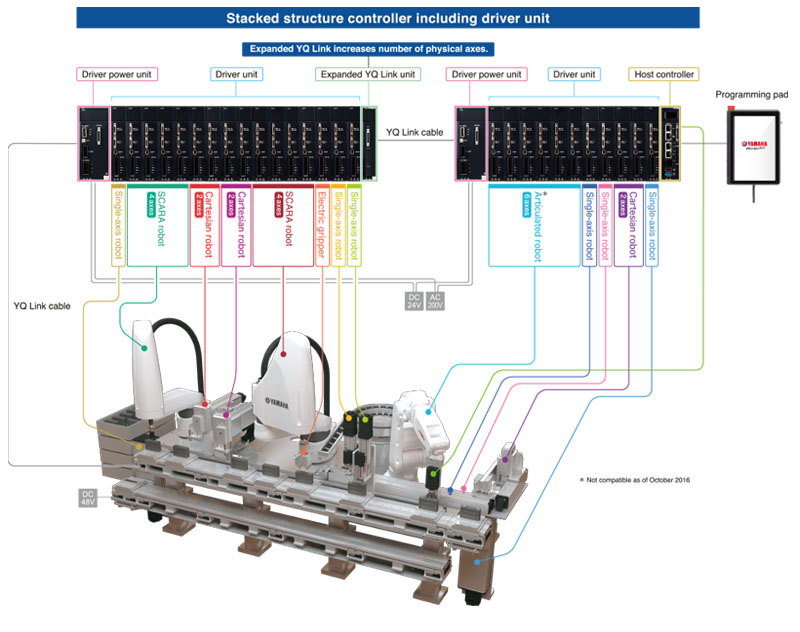

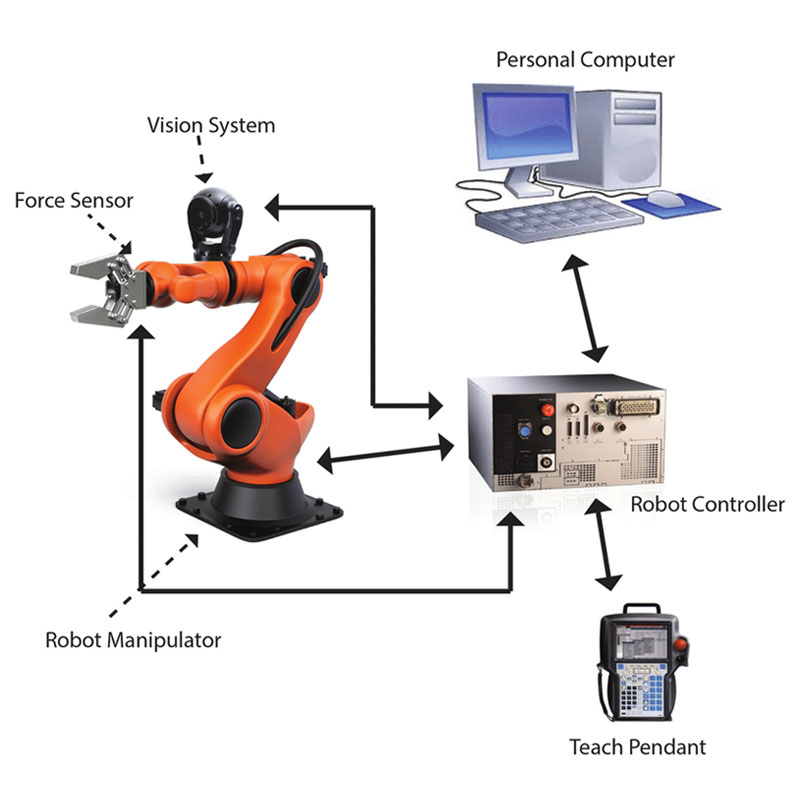

Industrial Robot Working: The working of industrial robots involves a combination of advanced sensors, programming, and mechanical components. These robots are designed to perform repetitive tasks with high accuracy, which significantly enhances productivity and reduces human error. They can operate in hazardous environments and execute tasks that are physically demanding.

Industrial Robotic Automation: Industrial Robotic Automation refers to the use of robots to automate various industrial processes. By incorporating robots, manufacturers can streamline operations, increase production rates, and improve product quality. Robotic Automation also helps in reducing labor costs, as fewer human workers are required to perform repetitive tasks.

Industrial Robotics and Automation: Industrial robotics and automation go hand in hand, offering a wide range of benefits to the manufacturing sector. Robotics and automation systems enable companies to achieve higher levels of precision, efficiency, and productivity. They also enhance workplace safety by minimizing the risk of accidents and injuries.

In conclusion, the integration of robots into the steel industry has brought about significant advancements in industrial operations. The use of industrial robots has improved productivity, accuracy, and workplace safety. The future of the steel industry is undoubtedly reliant on the continued development and implementation of robotics and automation technologies.