Robot In Petroleum Industry Solution

Robot In Petroleum Industry Solution:

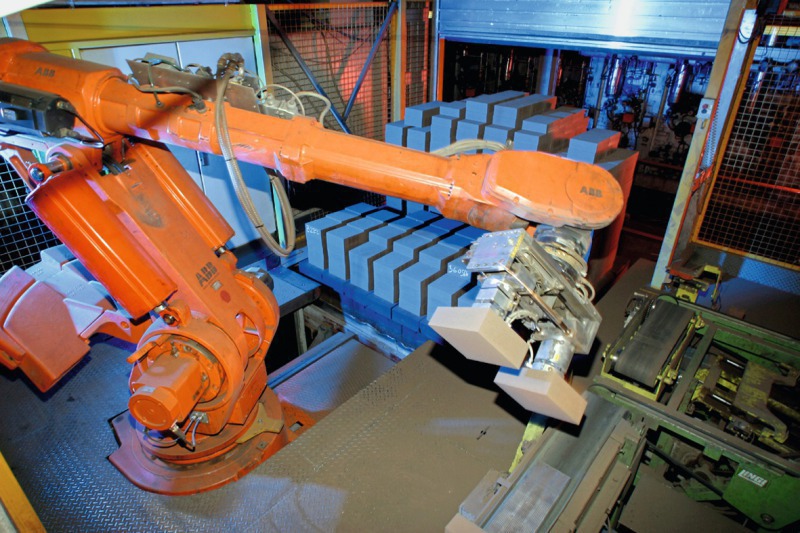

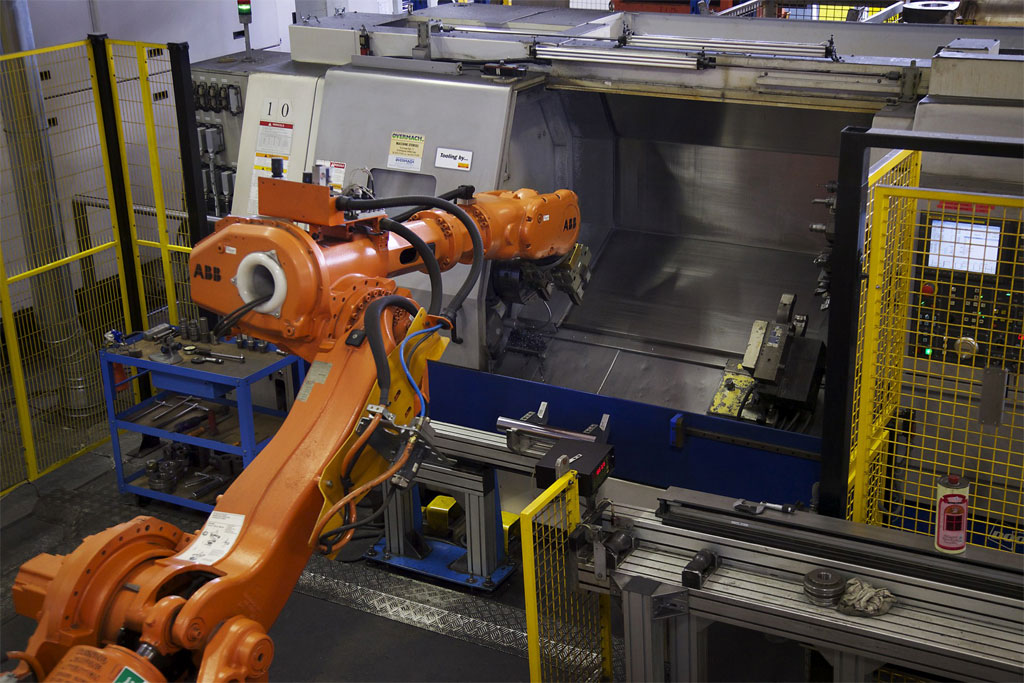

1,Efficiency: Robots in the petroleum industry are capable of performing tasks with increased efficiency and accuracy compared to human workers. They can work non-stop for long periods of time without getting tired or requiring breaks, thereby improving productivity.

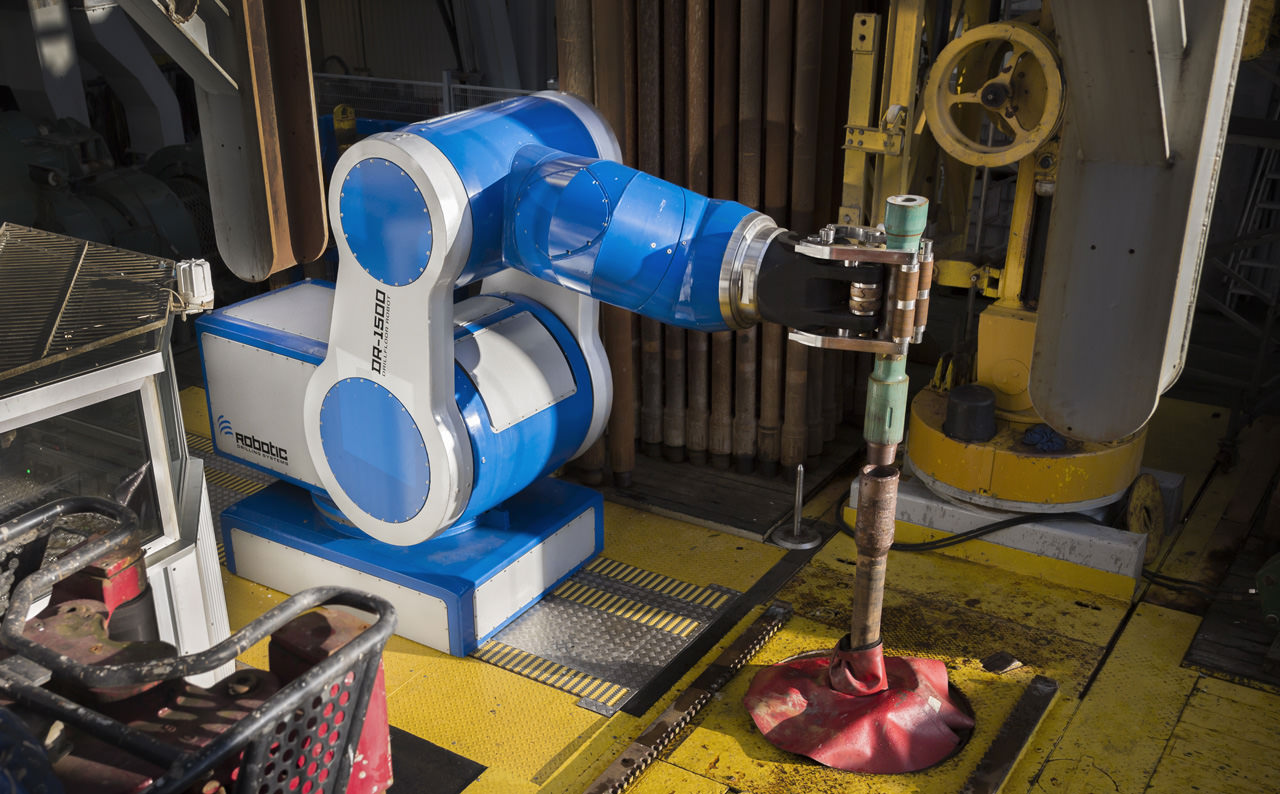

2,Safety: Robots can be deployed to carry out high-risk and dangerous tasks in the petroleum industry, such as inspection of pipelines, tankers, and offshore platforms, without putting human workers at risk. This helps to minimize accidents and ensures the safety of workers.

3,Cost-effectiveness: Implementing robots in the petroleum industry can lead to cost savings in the long run. While initially, the investment in robotics may be higher, they can significantly reduce operational costs by reducing the need for human labor and improving overall efficiency. This can result in increased profitability for petroleum companies.

Please Contact Us For Detailed Technical Parameters.

Robot In Petroleum Industry Solution:

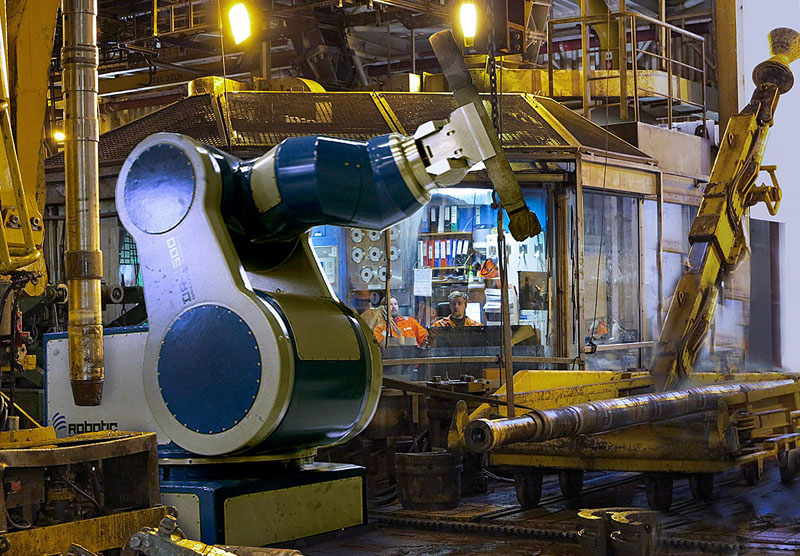

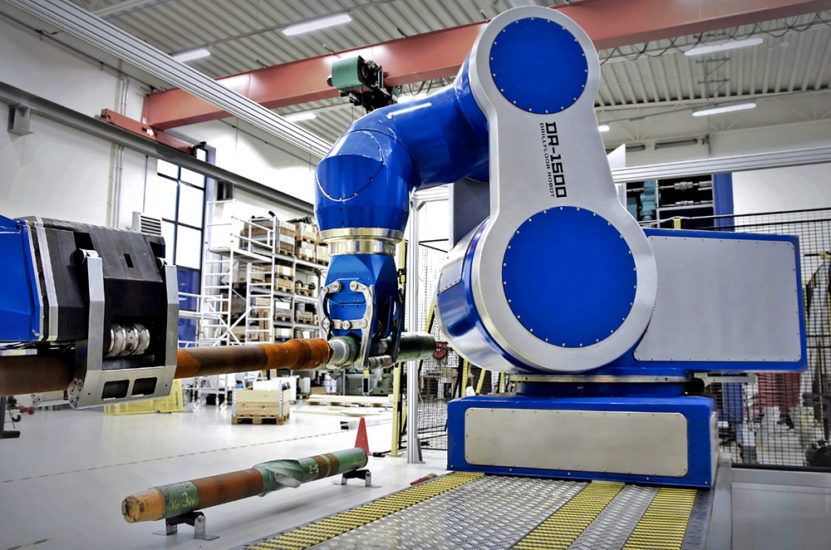

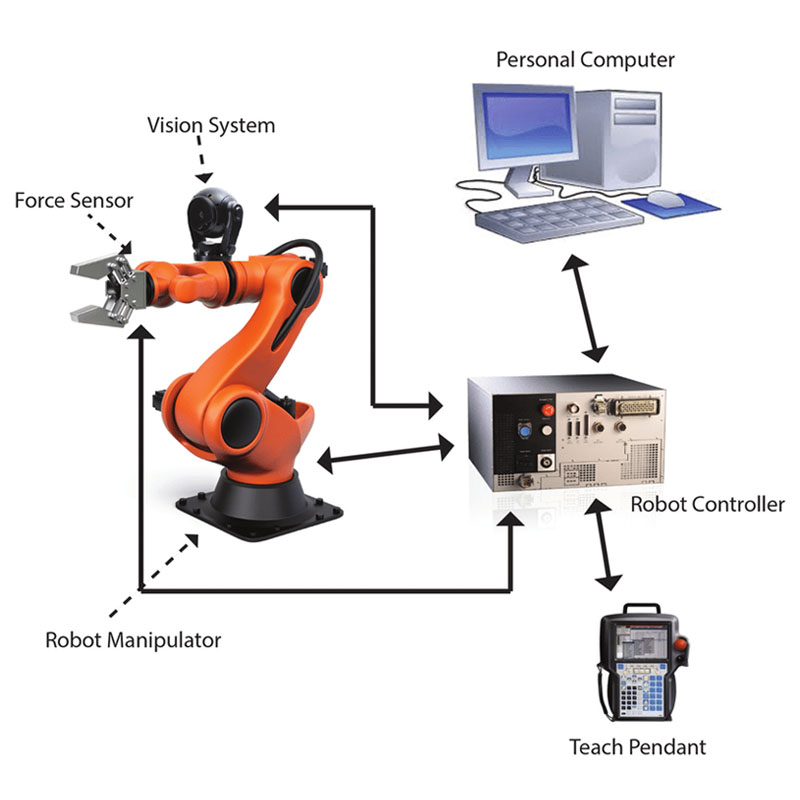

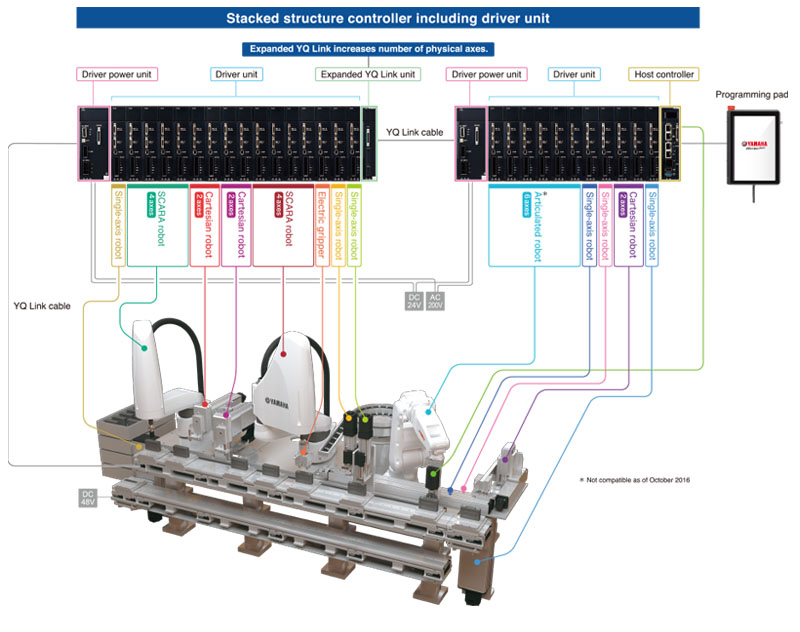

In the petroleum industry, the use of robotics has provided numerous advantages. Inspection robotics plays a vital role in the oil and gas industry by ensuring the safety and efficiency of operations. These robots are designed to perform inspections in hazardous environments, such as pipelines, tankers, and offshore platforms, reducing the risk for human workers. Robotics technology also allows for increased accuracy and efficiency, leading to improved productivity. The use of robotics in the oil and gas industry is not only cost-effective in the long run but also ensures the safety of workers and ultimately enhances profitability.