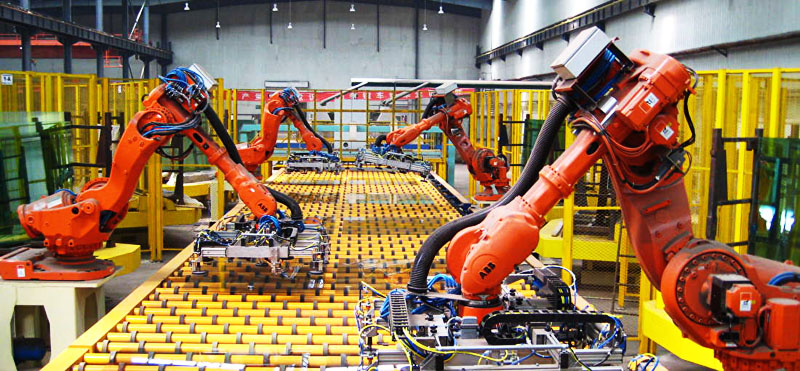

Robot Packaging Line Solution

Robot Packaging Line Solution:

1,Increased productivity: The implementation of a robot packaging line significantly boosts productivity. Robots can work continuously without breaks, leading to faster packaging rates and reduced cycle times. This allows for higher production capacity and meeting customer demands more efficiently.

2,Improved accuracy and consistency: Robot packaging lines ensure precise and consistent packaging. They can handle items with precision, ensuring accurate placement and alignment. This reduces the risk of packaging errors and enhances the overall quality of packaged products.

3,Cost savings: Robot packaging lines can lead to significant cost savings. By automating the packaging process, it reduces the need for manual labor, saving on labor costs and associated expenses. Additionally, robots optimize material usage, minimizing waste and reducing packaging costs in the long run.

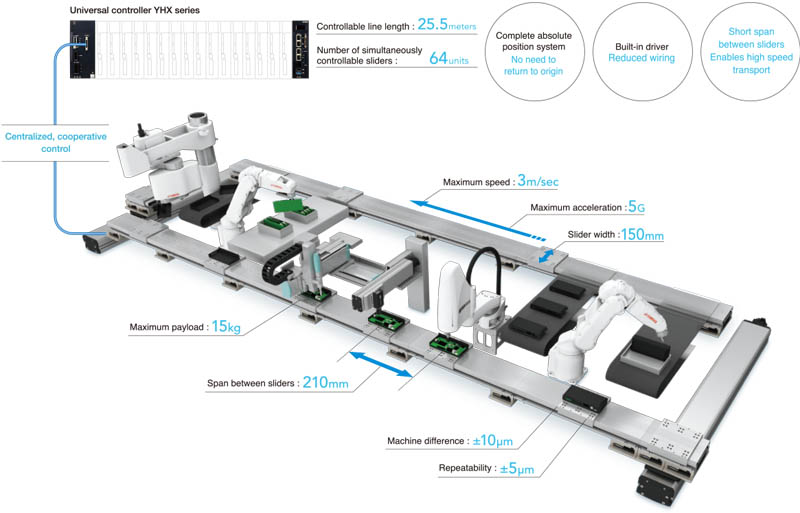

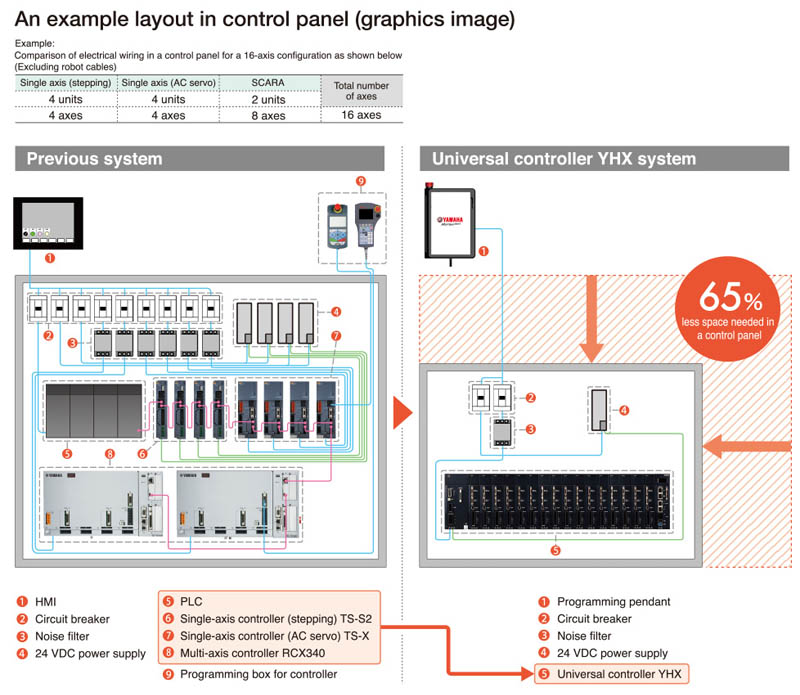

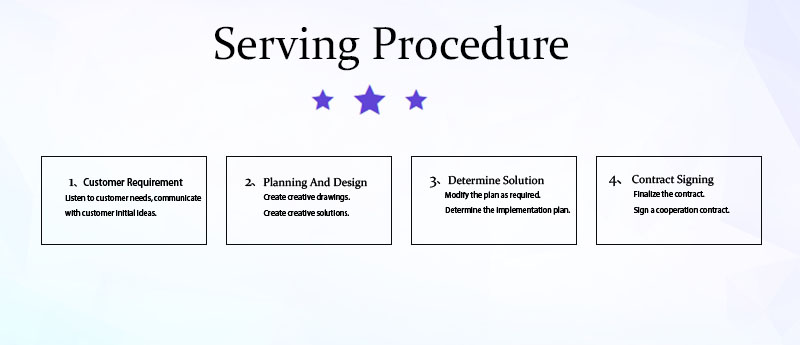

Please Contact Us For Detailed Technical Parameters.

Robot Packaging Line Solution:

The implementation of a robot packaging line in industries has revolutionized the way products are packaged, particularly in the case of bottles. Using robots for packaging bottles brings numerous advantages. Robot packaging automation ensures speed, precision, and consistency in the packaging process. With their dexterity and programming flexibility, robots can handle various bottle shapes, sizes, and materials efficiently. Additionally, robots reduce the risk of errors and improve overall packaging quality. Furthermore, the use of robots in packaging saves time, labor costs, and minimizes the chances of injuries. Overall, utilizing robot packaging lines offers significant advantages, making it an attractive choice for industries aiming to streamline their packaging operations and deliver high-quality products to consumers.