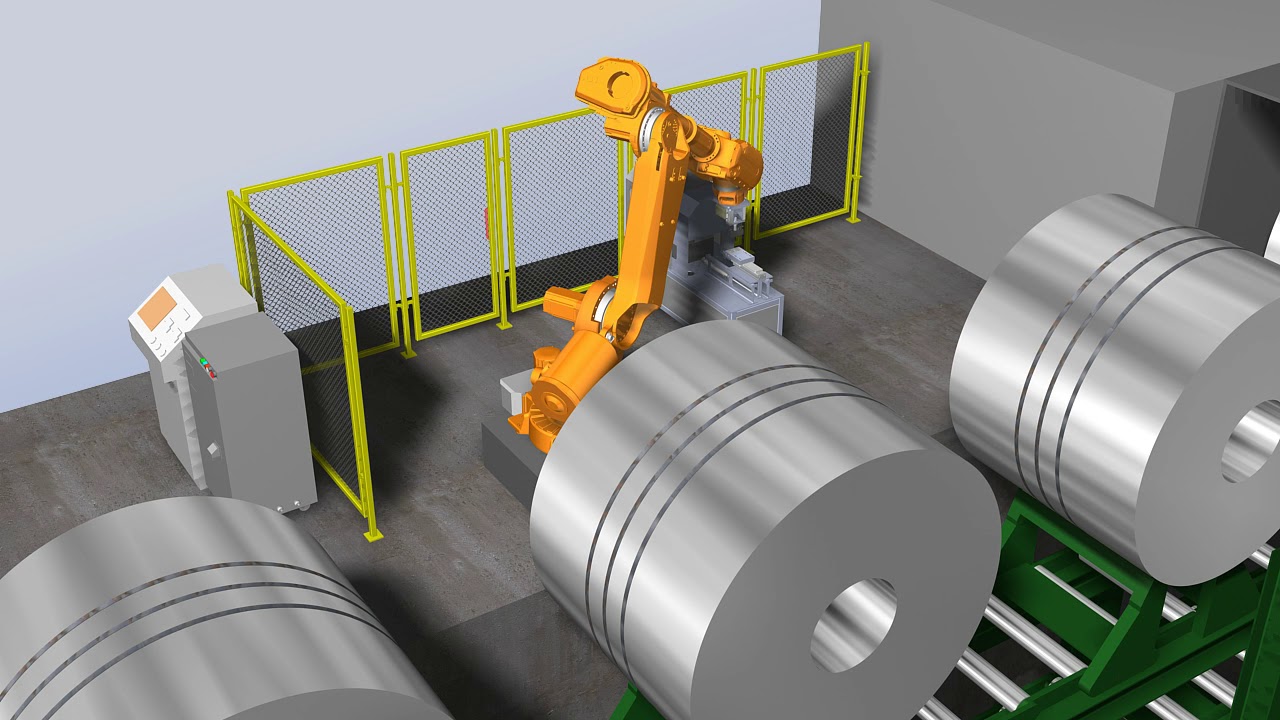

Robot In Metal Processing Industry

Robot In Metal Processing Industry:

1,Increased productivity: Robots can work continuously without getting tired or needing breaks, leading to higher output and faster processing times.

2,Improved accuracy: Robots are programmed to perform tasks with precision, resulting in consistent and accurate results. This reduces errors and waste in metal processing operations.

3,Enhanced safety: By automating tasks that are dangerous or physically demanding, robots help to ensure the safety of workers in the metal processing industry. This reduces the risk of accidents and injuries.

Please Contact Us For Detailed Technical Parameters.

Robot In Metal Processing Industry:

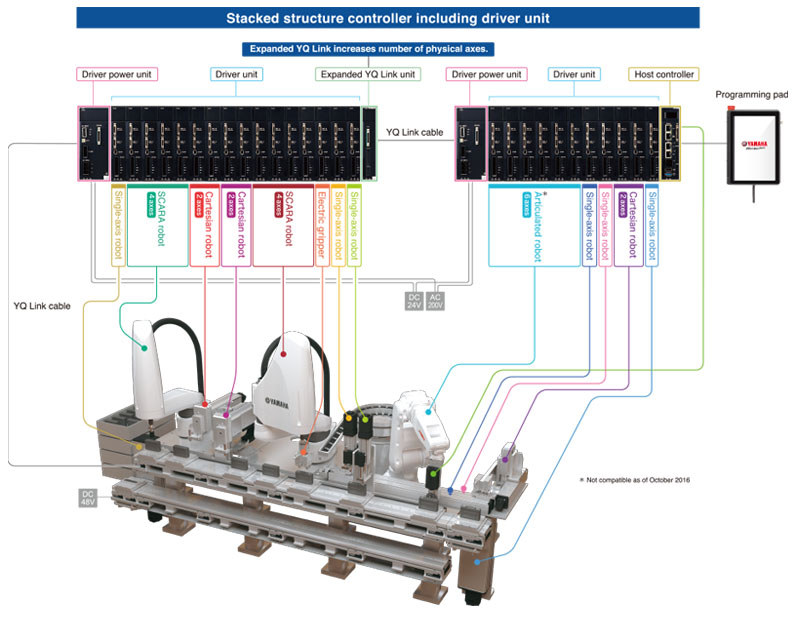

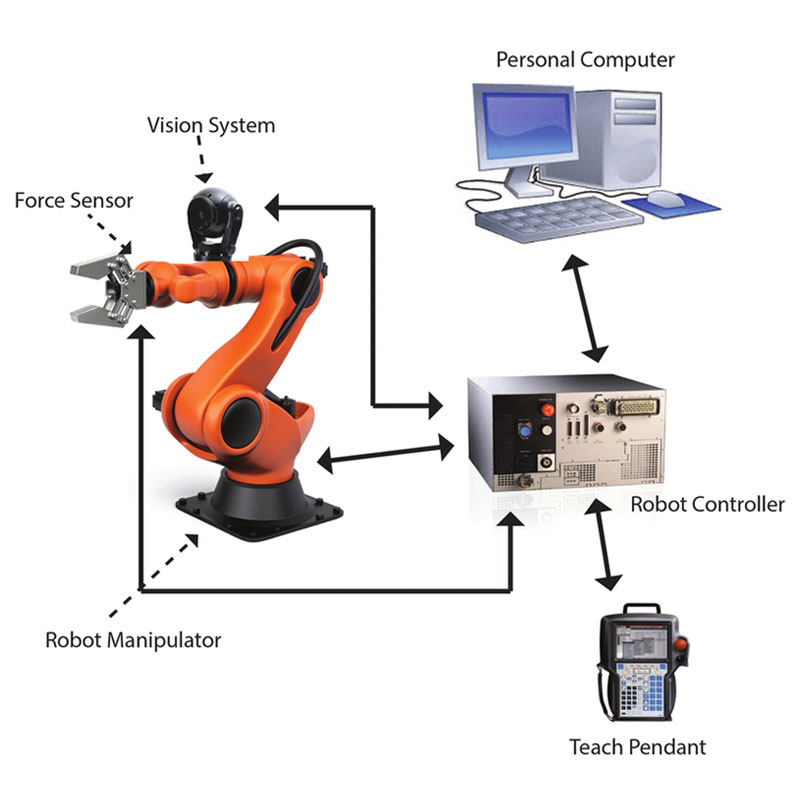

The use of robotic technology in the metal processing industry has revolutionized the way metallic components are fabricated and assembled. One such advancement is the metallic robot arm, which has greatly enabled the automated assembly of robots themselves.

The process of assembling a robot involves intricate and precise tasks that are best suited for robotic automation. By employing robots in this process, manufacturers can ensure higher accuracy and efficiency. The metallic robot arm, equipped with sensors and advanced programming, can perform tasks such as picking and placing components, tightening screws, and conducting quality checks with great precision.

Assembly in robotics has become faster and more reliable, thanks to the implementation of robots. With their tireless and consistent performance, robots can work for extended periods without fatigue or errors, resulting in increased productivity. Additionally, the use of robots in assembly processes enhances worker safety, as manual and repetitive tasks are transferred to robots, reducing the risk of injuries.

In conclusion, the integration of metallic robot arms and robotic automation in the assembly of robots has transformed the metal processing industry. This technological advancement has not only improved productivity and accuracy but has also led to safer working environments.