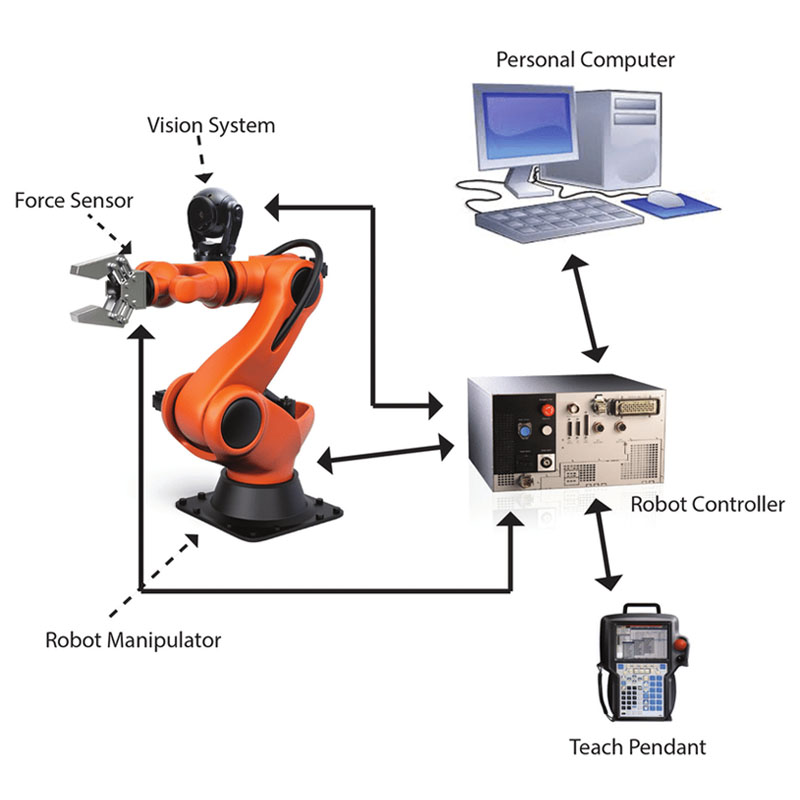

Packaging With Robots Solution

Packaging With Robots Solution:

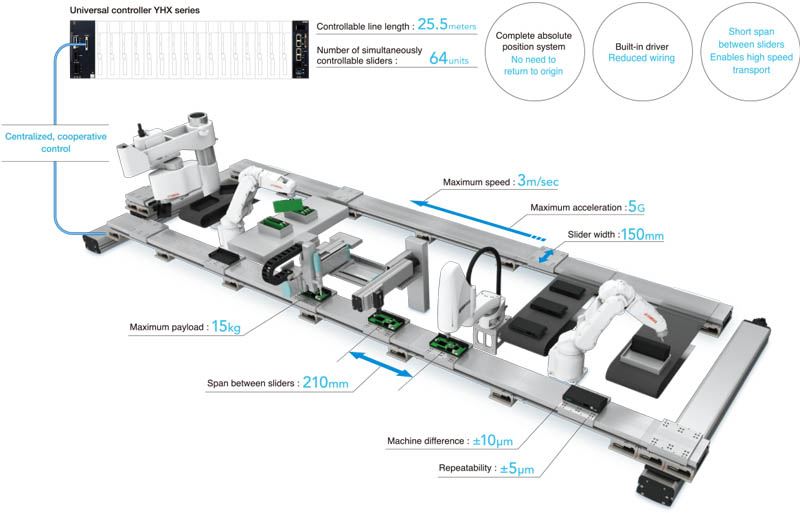

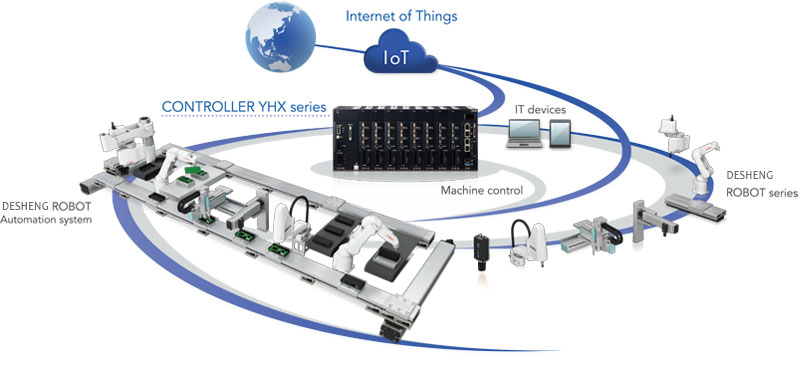

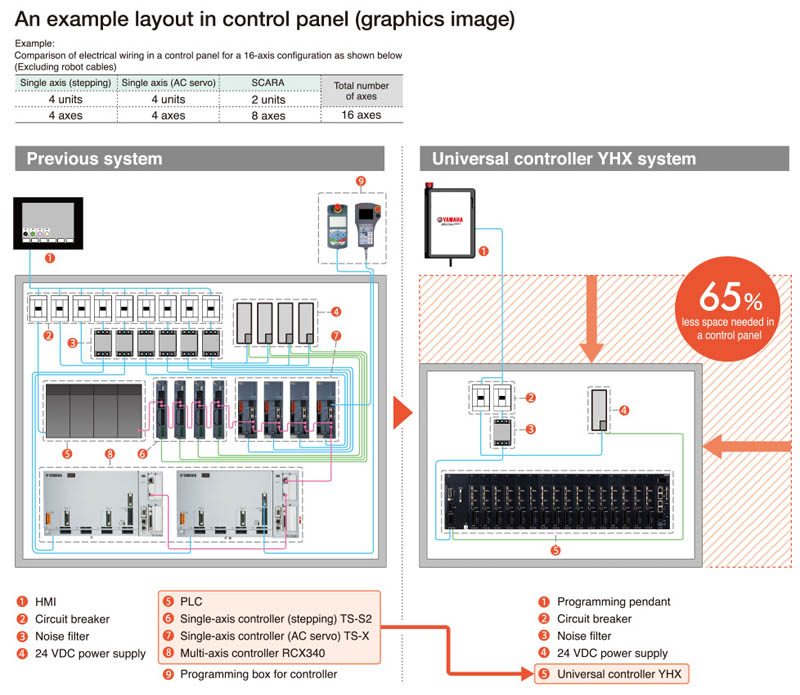

1,Increased speed and productivity: Packaging with robots allows for faster and more efficient packaging processes. Robots can work at a consistent speed without the need for breaks or rest, leading to increased production rates and shorter cycle times.

2,Improved accuracy and consistency: Robots can perform packaging tasks with a high level of precision and accuracy. They can consistently apply labels, fill containers, or arrange products with minimal errors. This results in improved packaging quality and reduces the risk of product defects or customer dissatisfaction.

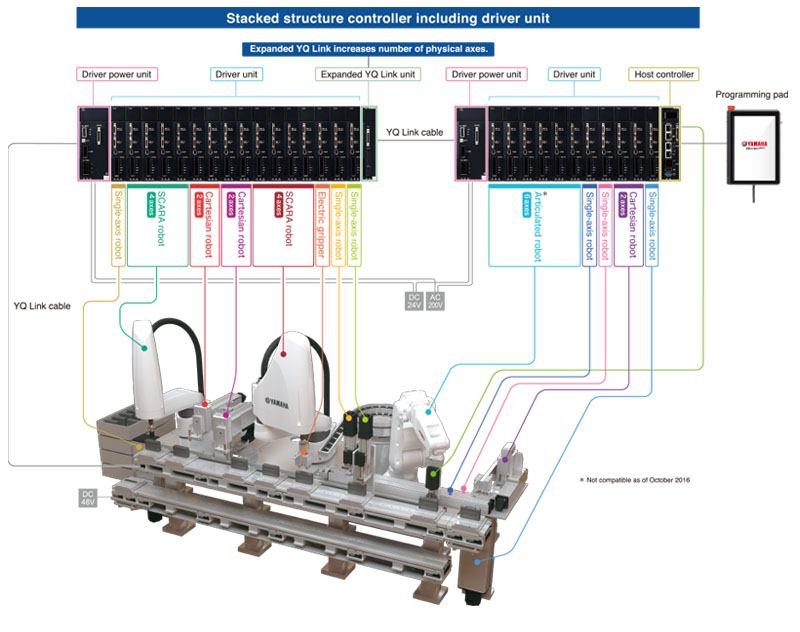

3,Flexibility and adaptability: Packaging with robots offers versatility and adaptability to changing packaging requirements. Robots can easily be programmed to handle different sizes, shapes, and materials, allowing for quick and seamless transitions between various packaging tasks. This flexibility enables manufacturers to meet varying customer demands and respond to market trends effectively.

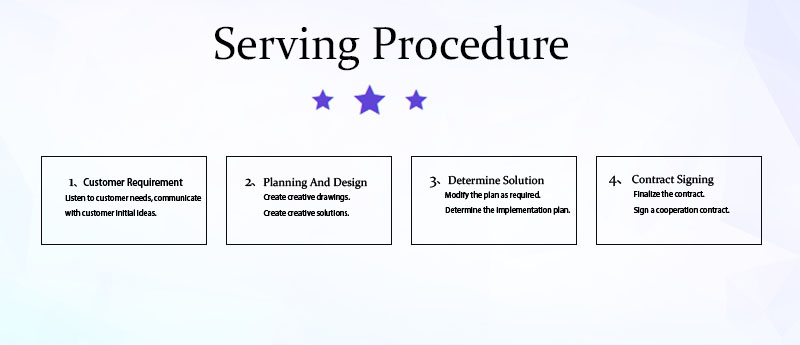

Please Contact Us For Detailed Technical Parameters.

Packaging With Robots Solution:

Packaging with robots has become a game-changer in various industries, especially when it comes to battery packs for robot cars. These delicate components require careful handling and secure packaging. With the use of robots, the packaging process becomes more efficient and precise. Companies can rely on robots to package battery packs with the utmost care, ensuring their safe transportation and storage. The integration of robots in the packaging process enables businesses to streamline operations, reduce errors, and increase productivity. As the demand for robot cars continues to rise, the use of robots for packaging battery packs ensures that these essential components are well-protected and ready for installation in the final product.