Material Handling In Robotics

Material Handling In Robotics

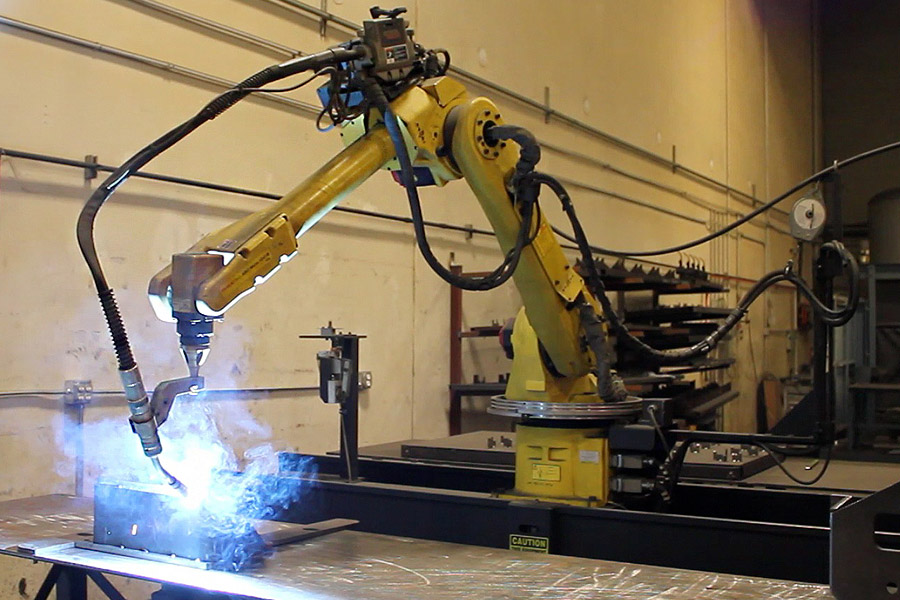

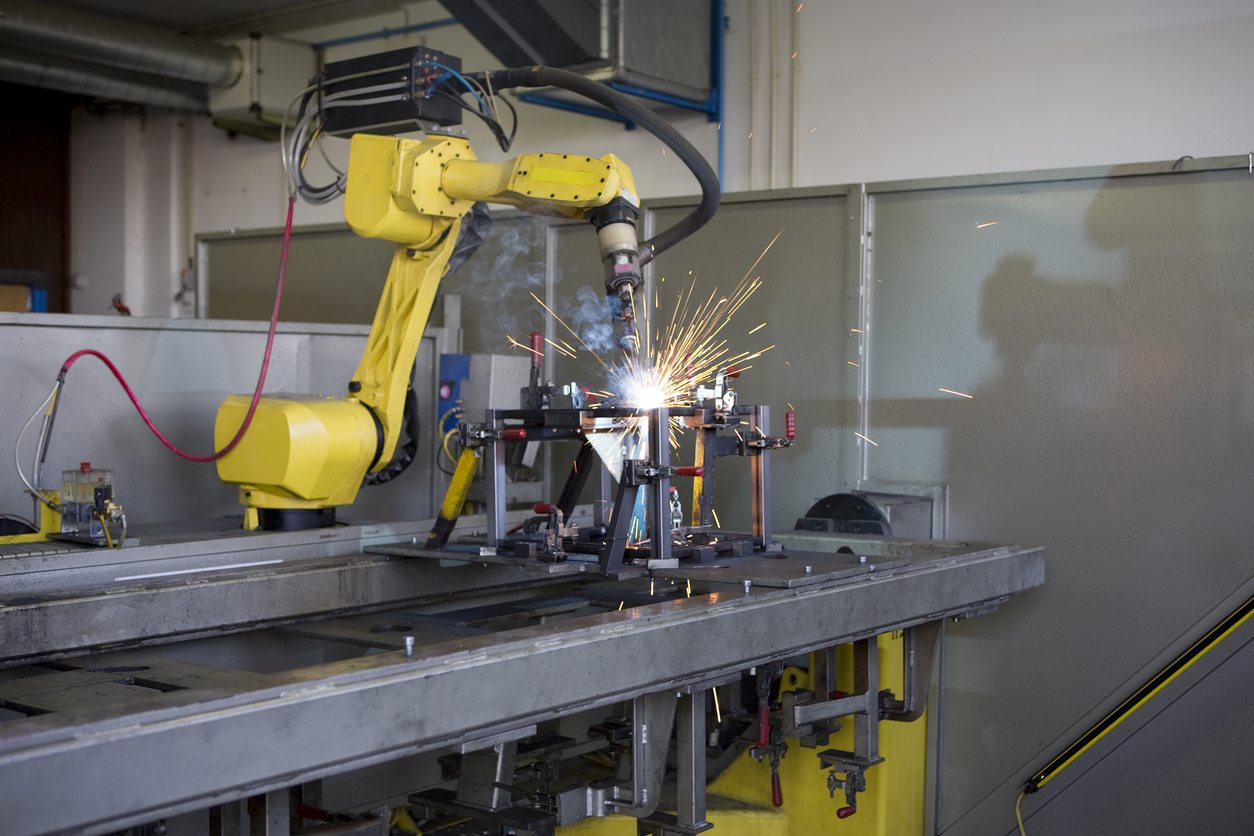

Material handling in robotics offers several advantages. Firstly, it improves efficiency by automating the movement, organization, and transportation of materials, reducing the need for manual labor and saving time. Secondly, it enhances safety by reducing the risk of injuries associated with lifting and carrying heavy objects. Thirdly, it increases accuracy and precision in material handling tasks, minimizing the chances of errors and damage. Additionally, it optimizes space utilization by maximizing storage capacity and streamlining workflows. Moreover, it enables real-time monitoring and data collection, facilitating better inventory control and supply chain management. Overall, material handling in robotics improves productivity, reduces costs, and enhances overall operational effectiveness.

Material Handling In Robotics

Material handling in robotics has become increasingly important in various industries. Companies like Kuka, known for their powerful and versatile Kuka KR 1000 Titan, are leading the way in providing innovative solutions. While the price of the Kuka KR 1000 Titan may be high, the benefits it offers in terms of efficiency and productivity justify the investment. Additionally, there are other reputable robotics companies worldwide that excel in material handling, such as ABB, Fanuc, and Yaskawa. These companies offer a range of robotic solutions, including machinery automation and robotics, to optimize manufacturing processes. With the continuous advancements in material handling robotics, industries can expect improved efficiency and cost-effectiveness.