Industrial Inspection Robots

Industrial Inspection Robots

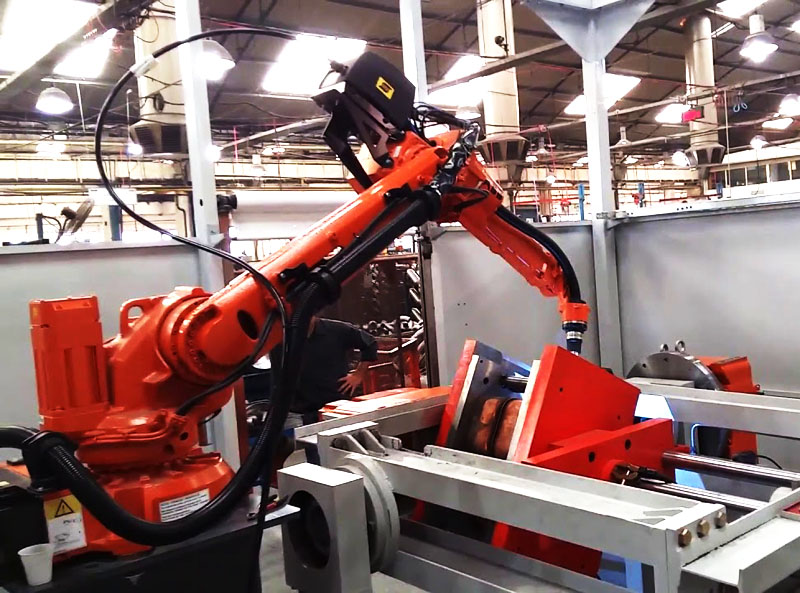

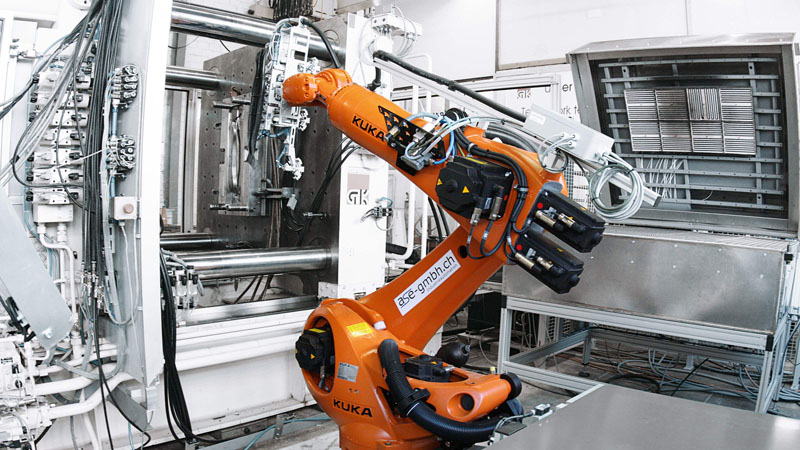

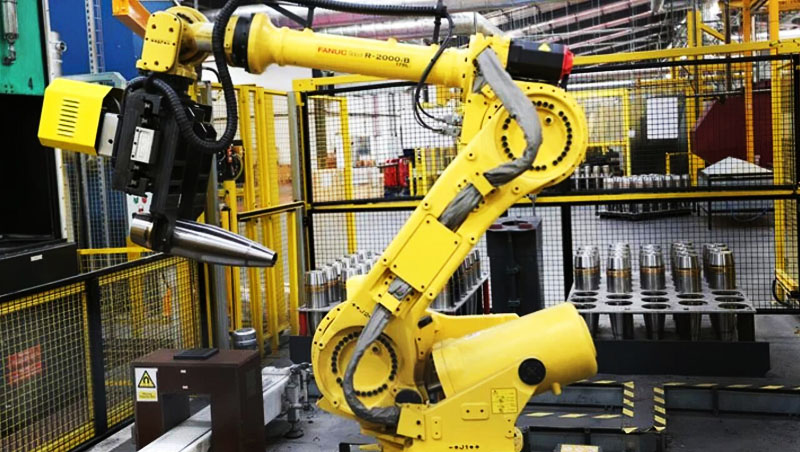

Industrial inspection robots offer several advantages in various industries. Firstly, they can perform inspections in hazardous or hard-to-reach areas, reducing human exposure to risks. Secondly, these robots are equipped with advanced sensors and cameras, enabling them to detect defects, anomalies, or quality issues with high accuracy and precision. Moreover, inspection robots facilitate faster and more consistent inspections, resulting in increased productivity and reduced downtime. They can also collect and analyze vast amounts of data, providing valuable insights for process optimization and predictive maintenance. Overall, industrial inspection robots improve efficiency, safety, and quality in inspections, making them invaluable tools in industries such as manufacturing, energy, and infrastructure.

Industrial Inspection Robots

Industrial inspection robots, along with robotic packaging systems and the integration of industrial robotics and digital manufacturing, are transforming the manufacturing sector. Industrial inspection robots enhance quality control processes by providing consistent and accurate inspections. Robotic packaging systems streamline packaging operations, improving efficiency and reducing errors. The integration of industrial robotics and digital manufacturing optimizes production processes, enhancing productivity and flexibility. Additionally, the versatile Mir100 robot plays a crucial role in various industries, performing tasks such as material handling and logistics. Together, these technologies and solutions are revolutionizing the manufacturing landscape, driving automation, and enabling businesses to achieve higher levels of efficiency and competitiveness in the market.