Electronics Pick And Place Robot

Electronics Pick And Place Robot:

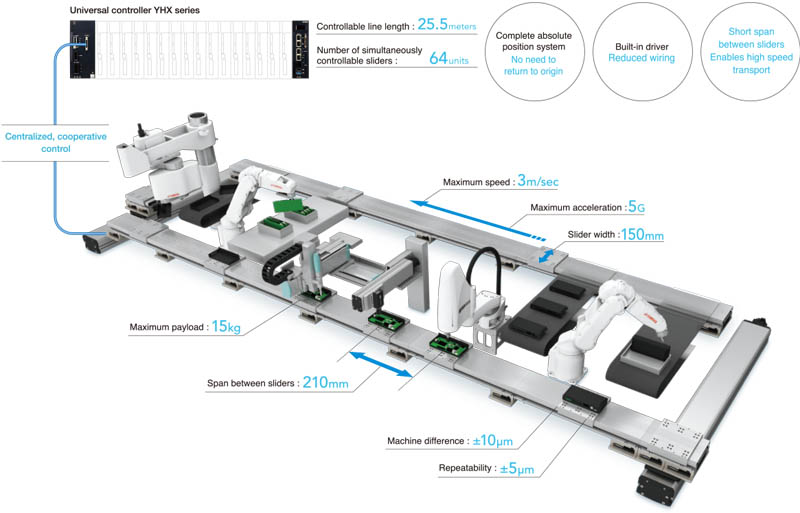

The Electronics Pick and Place Robot offers significant advantages in the electronics manufacturing industry. With its precise and efficient automation capabilities, this robot revolutionizes the assembly process of electronic components.

One key advantage is speed. The Pick and Place Robot can swiftly handle and place electronic components onto circuit boards with high accuracy and precision. This speed ensures faster production cycles, leading to increased productivity and shortened time-to-market.

Additionally, the robot's accuracy and repeatability contribute to improved quality control. It can precisely position components in accordance with the design specifications, minimizing errors and reducing the risk of faulty connections or defective products. With its ability to consistently repeat tasks, the robot ensures uniformity and reliability in the manufacturing process.

Moreover, the Pick and Place Robot enhances worker safety by reducing manual labor and potential ergonomic risks associated with repetitive tasks. By taking over the repetitive and monotonous work, it frees up human operators to focus on more complex and value-added tasks, promoting a safer and healthier working environment.

Lastly, the robot's versatility allows it to adapt to various production requirements and component sizes. It can handle a wide range of electronic parts, enabling flexibility in manufacturing and facilitating scalability as production demands change.

In summary, the Electronics Pick and Place Robot's advantages lie in its speed, accuracy, quality control, worker safety, and versatility. These features make it an invaluable tool in the electronics manufacturing industry, improving efficiency, productivity, and overall product quality.

Electronics Pick And Place Robot:

In the realm of industrial automation, the Electronics Pick and Place Robot has emerged as a game-changer. Its capability to precisely handle electronic components has revolutionized the electronics manufacturing industry.

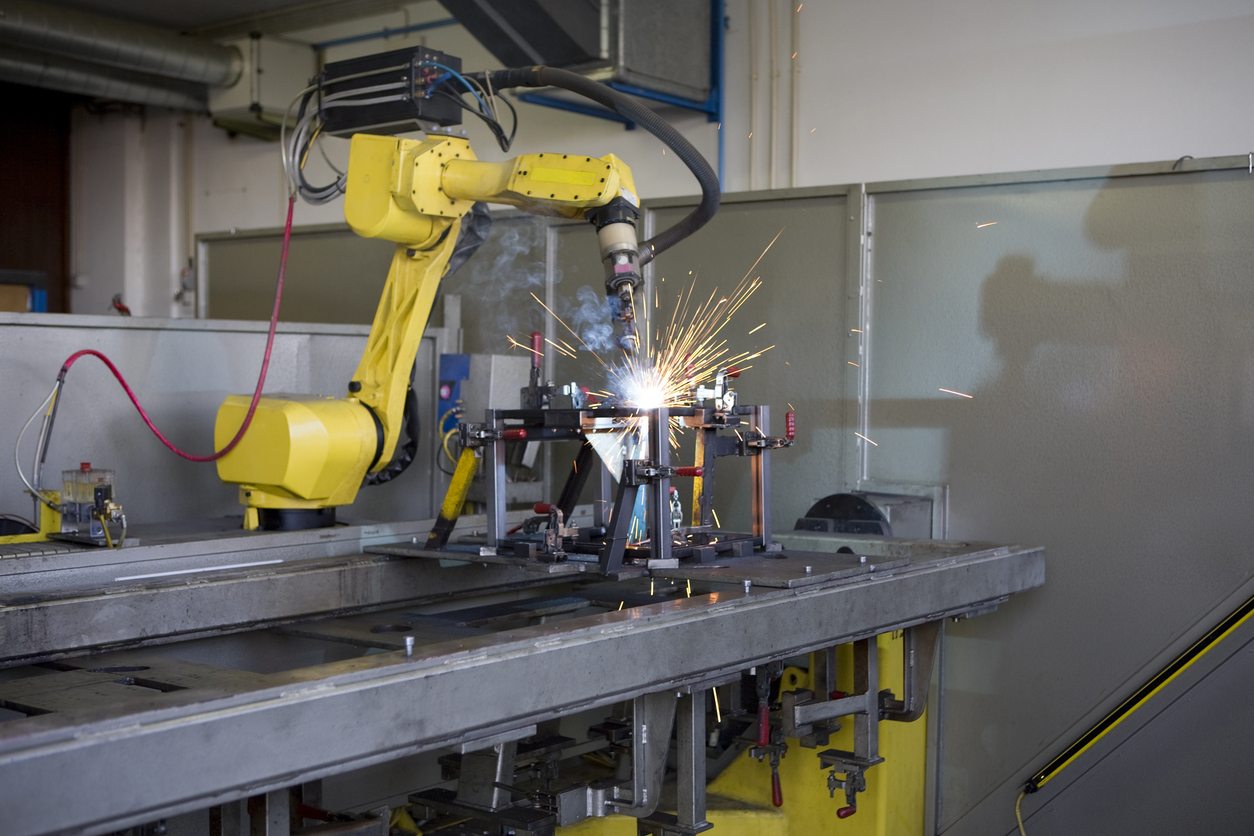

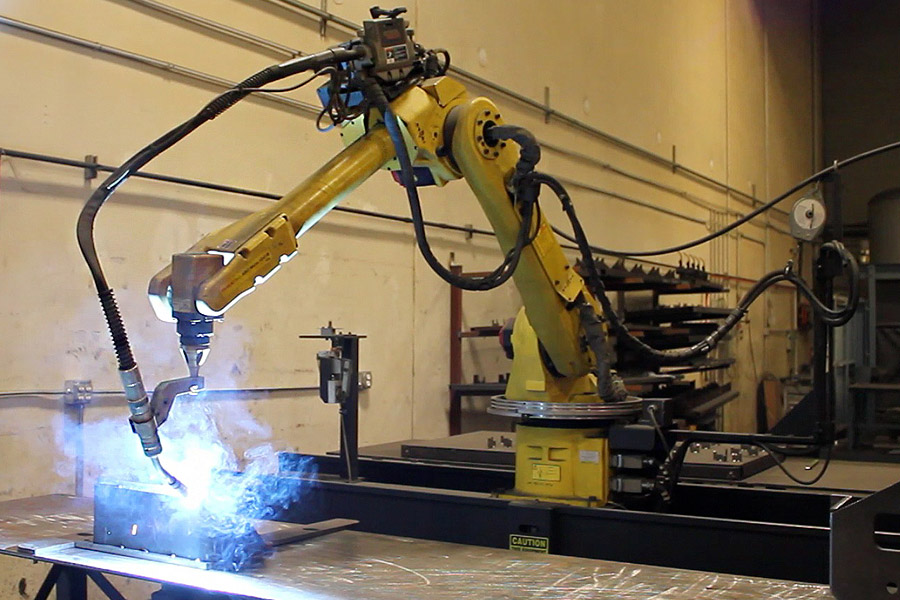

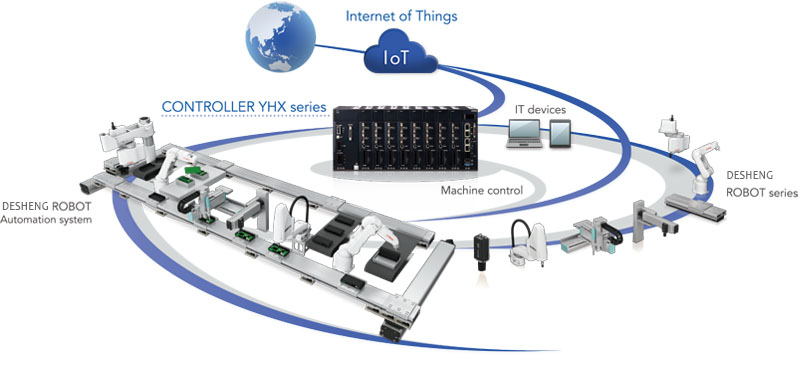

The Electronics Pick and Place Robot is part of the broader domain of industrial robots, which encompasses a wide range of robotic systems used in various sectors. As the demand for automation grows, so does the number of industrial robot manufacturers. Among the top 10 manufacturers are renowned companies such as Fanuc, ABB, KUKA, Yaskawa, and Universal Robots.

These manufacturers offer a diverse array of industrial robots, each with its own unique features and functionalities. From welding robots to assembly robots, they cater to different industries and applications. These robots improve productivity, enhance quality control, and optimize efficiency in manufacturing processes.

Industrial robots, including the Electronics Pick and Place Robot, have become indispensable in the electronics manufacturing sector. By automating the precise placement of components on circuit boards, these robots drastically reduce production time and increase product quality. They enable electronics manufacturers to meet the demands of an ever-evolving market swiftly and efficiently.

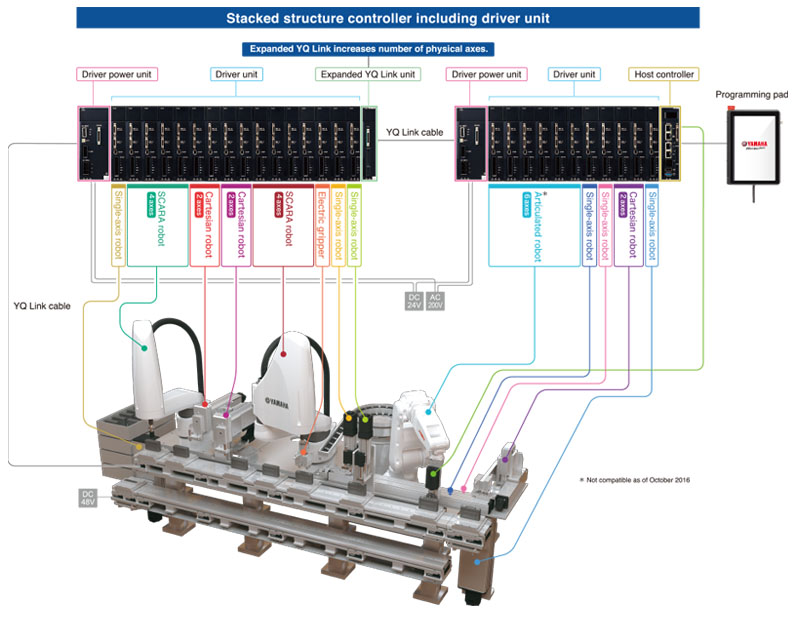

Furthermore, the integration of collaborative robots, or cobots, into industrial environments has opened up new possibilities. Cobots work in close proximity with human operators, aiding in tasks that require delicate interaction and flexibility. Their intuitiveness, safety features, and ease of use have made them popular choices for small and medium-sized enterprises.

In conclusion, the Electronics Pick and Place Robot stands as a prime example of the capabilities and impact of industrial robots in modern manufacturing. Together with the top 10 robot manufacturers, these robots are transforming industries worldwide, driving efficiency, innovation, and productivity.