Abb Robot Welding Program

Abb Robot Welding Program

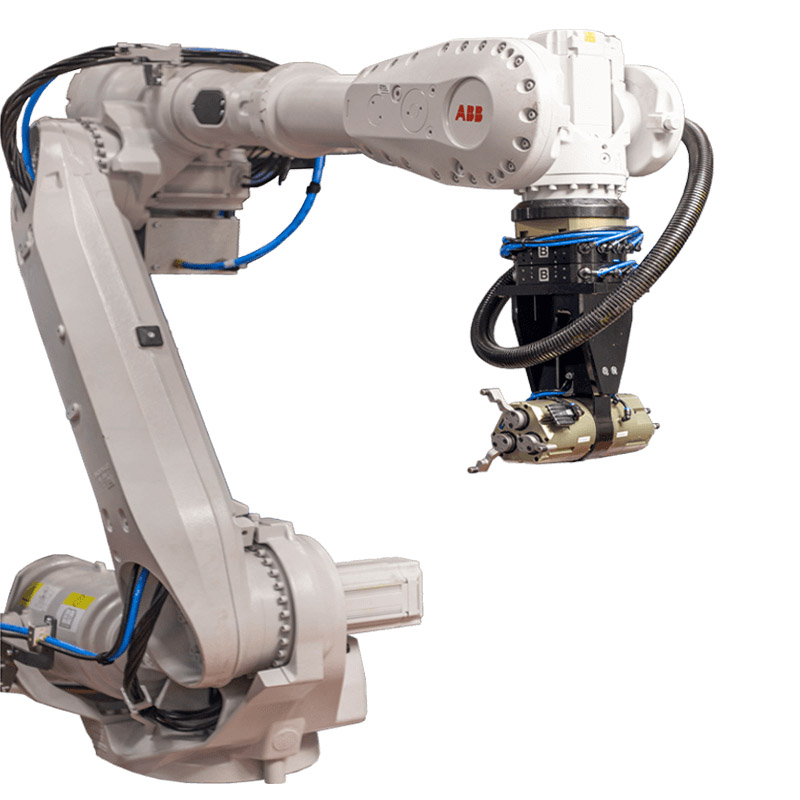

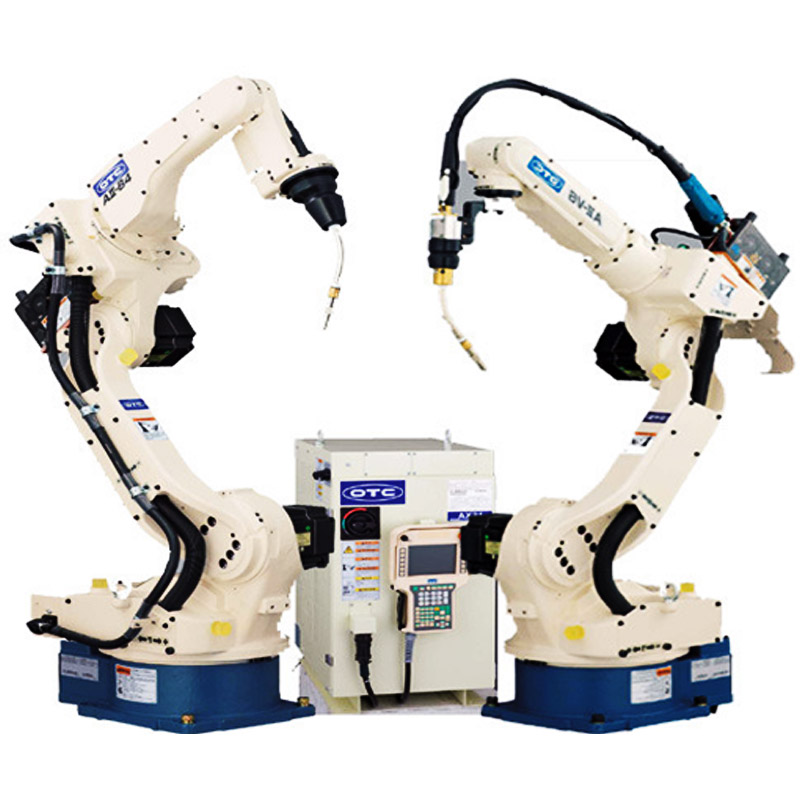

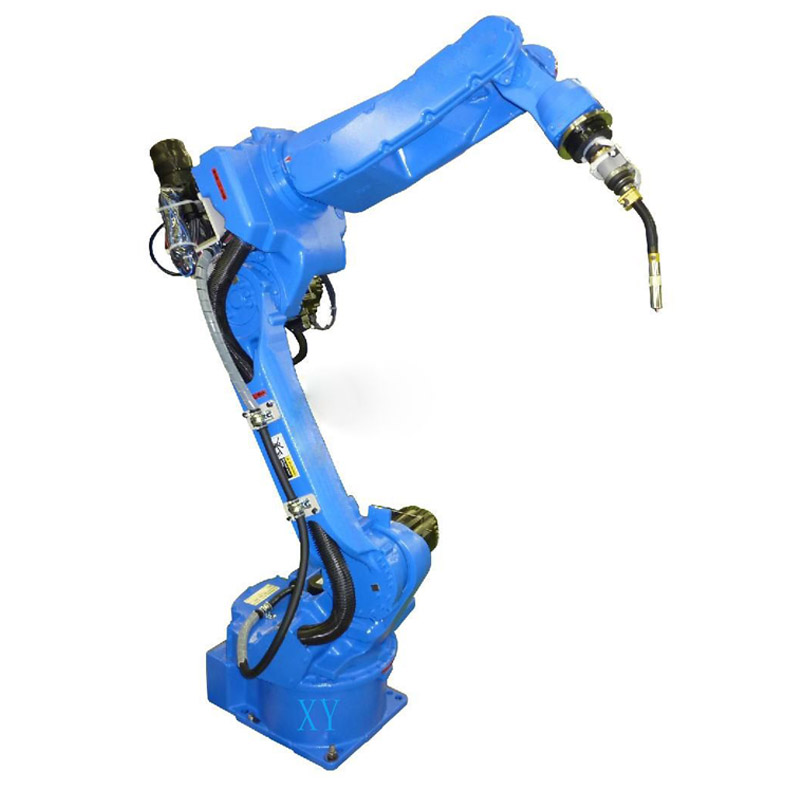

The advantages of the Abb Robot Welding Program include increased productivity, improved accuracy, and enhanced safety. The program allows for faster and more efficient welding processes, resulting in higher production rates and reduced cycle times. Additionally, the program ensures precise and consistent welds, minimizing the need for rework and improving overall product quality. Moreover, the use of robots reduces the risk of human error and injuries, making the welding process safer for operators. Overall, the Abb Robot Welding Program offers numerous benefits that can greatly enhance welding operations in terms of speed, accuracy, and safety.

Abb Robot Welding Program

The use of Abb Robot Welding Program and robotic welding machines has revolutionized the welding industry. These machines, manufactured by leading companies, have greatly increased efficiency and productivity in various sectors. One such industry that has greatly benefited from welding robots is the automotive industry. With the ability to perform complex welding tasks with precision and speed, these robots have become an integral part of automobile manufacturing. The use of welding industrial robots has not only improved the quality of welds but has also reduced labor costs and increased overall production. In conclusion, the advancement of welding robots has had a significant impact on the automotive industry and other sectors, making welding processes faster, more accurate, and cost-effective.