Welding Using Robotic Arm

Welding Using Robotic Arm:

1,Precision: Robotic arms can perform welding with exceptional accuracy and repeatability, ensuring consistent and high-quality welds. The programmed path and control systems enable precise placement of the welds, resulting in superior welding outcomes.

2,Efficiency: Robotic arms can work continuously without fatigue, leading to increased productivity and reduced production time. They can perform multiple welds simultaneously, significantly enhancing overall efficiency in the welding process and speeding up production.

3.Safety: By automating the welding process, robotic arms eliminate the need for humans to work in hazardous environments. This reduces the risk of injuries and exposure to harmful fumes, creating a safer workplace for the operators. Additionally, these arms are equipped with safety features like collision detection and emergency stop, ensuring safe operations.

Welding Using Robotic Arm:

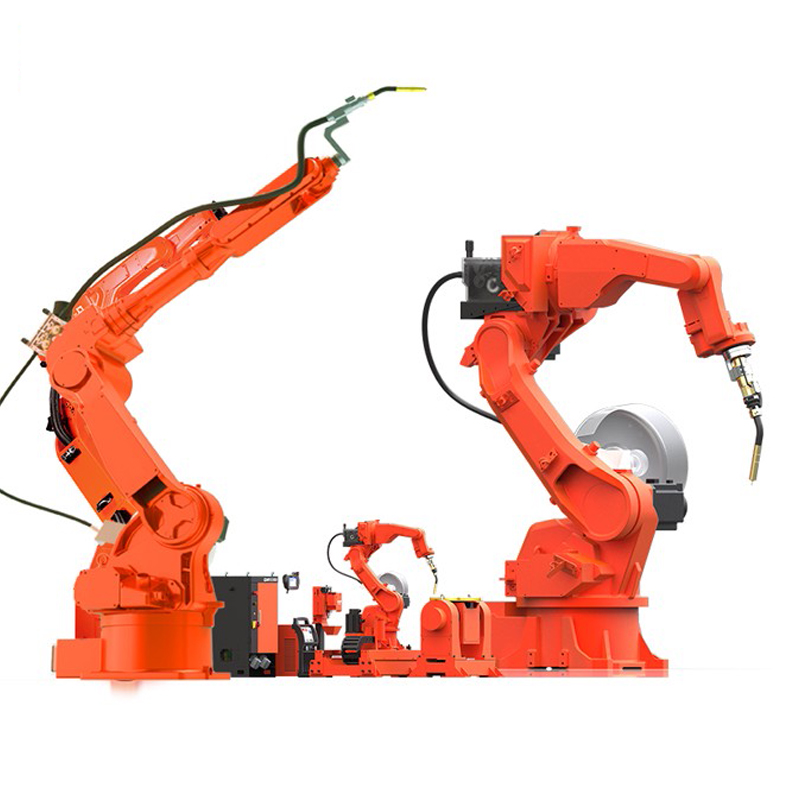

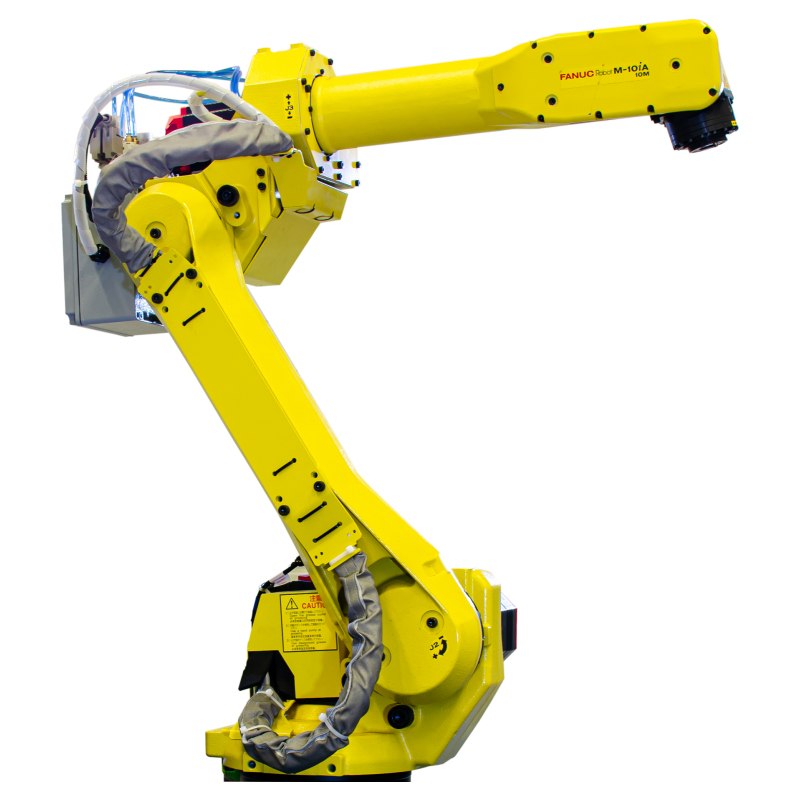

Welding using robotic arms has gained popularity in various industries. Robot Kuka Mexico and Fanuc Laser Robot are leading providers of advanced robotic systems for welding applications. These robots offer precise and efficient welding capabilities, delivering high-quality welds consistently.

Additionally, pick and place robots play a vital role in the welding process by handling and positioning the workpieces accurately, ensuring seamless welding operations. These robots enhance productivity by automating material handling tasks, allowing for faster workflow.

Overall, the combination of robotic arms from companies like Robot Kuka Mexico and Fanuc Laser Robot, along with the integration of pick and place robots, has revolutionized the welding industry. This technology offers improved efficiency, reliability, and consistency, making it an indispensable tool for modern manufacturing processes.