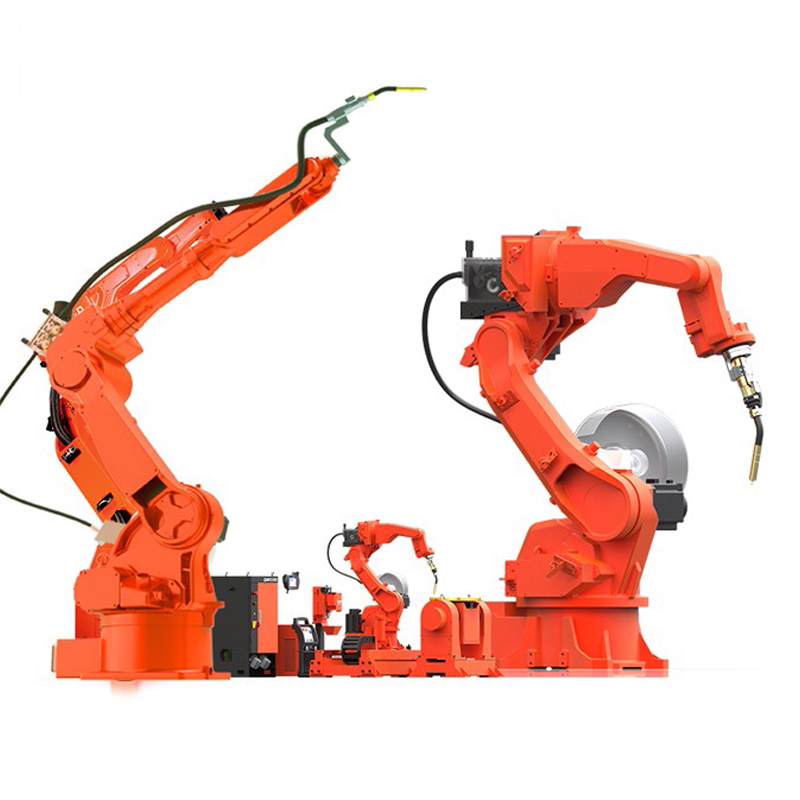

Welding Robot Arm Automotive

Welding Robot Arm Automotive:

1. Improved precision: Welding Robot Arms are programmed to perform precise and accurate welds, resulting in higher quality and consistency in automotive welding processes.

2. Increased productivity: These robotic arms can work continuously without the need for breaks or rest, leading to increased production rates and reduced cycle times in automotive manufacturing.

3. Enhanced safety: Welding Robot Arms eliminate the need for human welders to work in hazardous environments, reducing the risk of accidents and injuries. They also have built-in safety features, such as collision detection sensors, ensuring a safe working environment.

Welding Robot Arm Automotive:

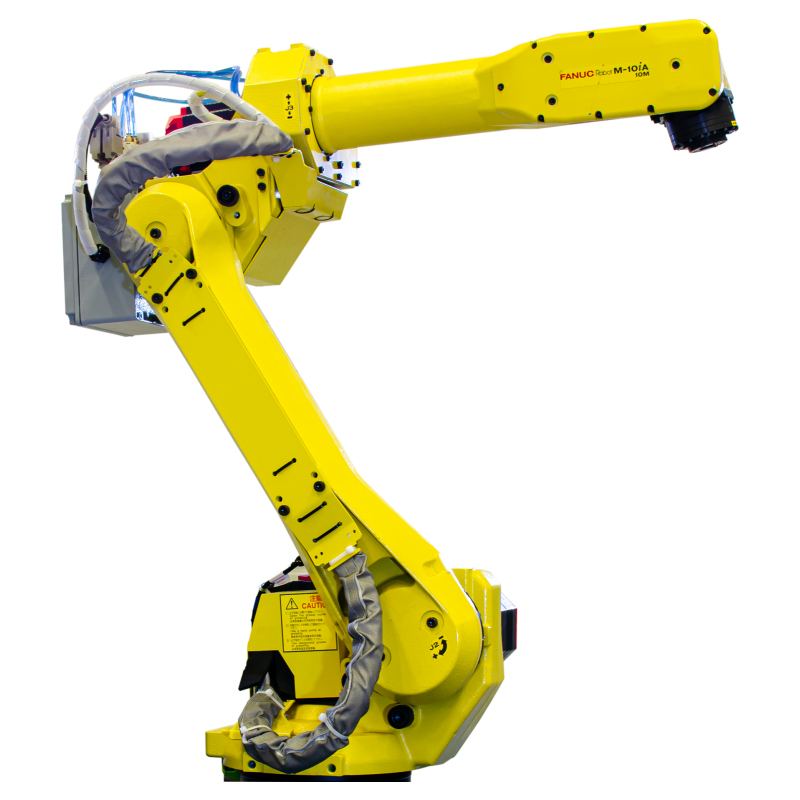

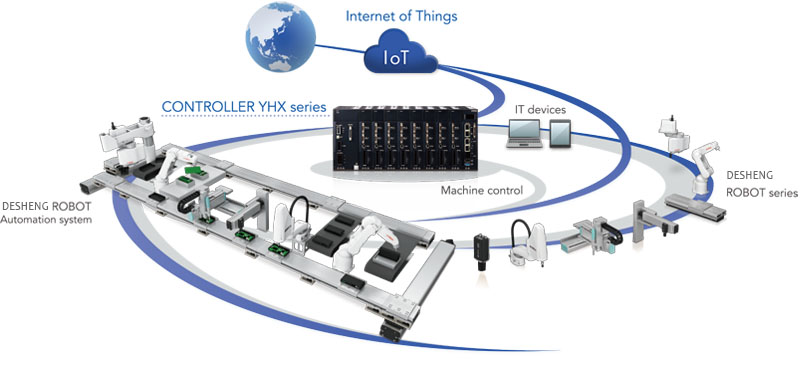

Welding Robot Arm Automotive, Kuka Machine Vision, Robotic Arm Kits, and Vision Robot Bin Picking are all advanced technologies in the field of robotics.

Welding Robot Arm Automotive refers to the use of robotic arms in the automotive industry for welding tasks. These robot arms are programmed to perform precise and repetitive welding tasks, resulting in improved efficiency and accuracy in the manufacturing process.

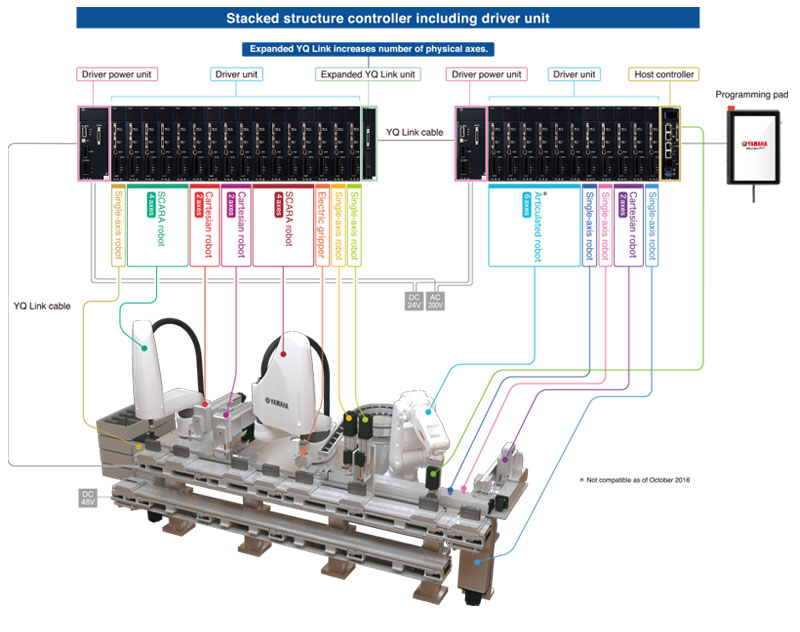

Kuka Machine Vision, on the other hand, is a technology that combines robotic arms with advanced vision systems. This allows the robot to analyze and interpret visual information, enabling it to perform tasks that require visual perception, such as object recognition and tracking.

Robotic Arm Kits are DIY kits that allow enthusiasts and hobbyists to build their own robotic arms. These kits come with all the necessary components and instructions for assembly. They are a great way to learn about robotics and explore the possibilities of robotic arm technology.

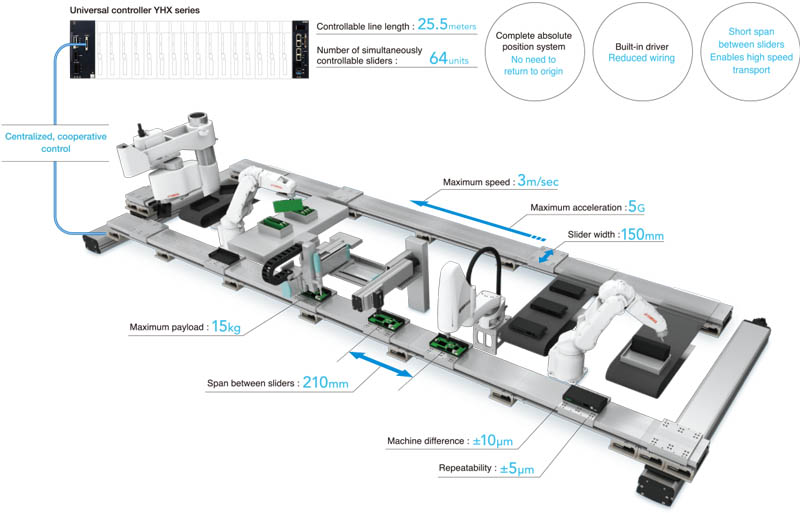

Vision Robot Bin Picking is a technology that combines machine vision and robotic arms to automate the process of picking objects from bins or containers. The vision system identifies the objects in the bin, and the robotic arm then picks them up and places them in the desired location. This technology is widely used in industries such as logistics and manufacturing.

Overall, these technologies are revolutionizing the way tasks are performed in various industries. They offer improved efficiency, accuracy, and flexibility, making them invaluable tools in the world of robotics.