Steel Industry Autonomous Robots

Steel Industry Autonomous Robots:

1,Increased productivity: Autonomous robots in the steel industry can work round the clock without breaks or fatigue, leading to increased productivity and efficiency in operations.

1,Improved safety: With autonomous robots taking over hazardous tasks such as handling heavy materials and working in high-temperature environments, the safety of human workers is significantly enhanced.

3,Cost savings: Autonomous robots can perform repetitive tasks with precision, reducing the need for manual labor and minimizing human error. This leads to cost savings in the long run by optimizing operations and minimizing wastage.

Steel Industry Autonomous Robots:

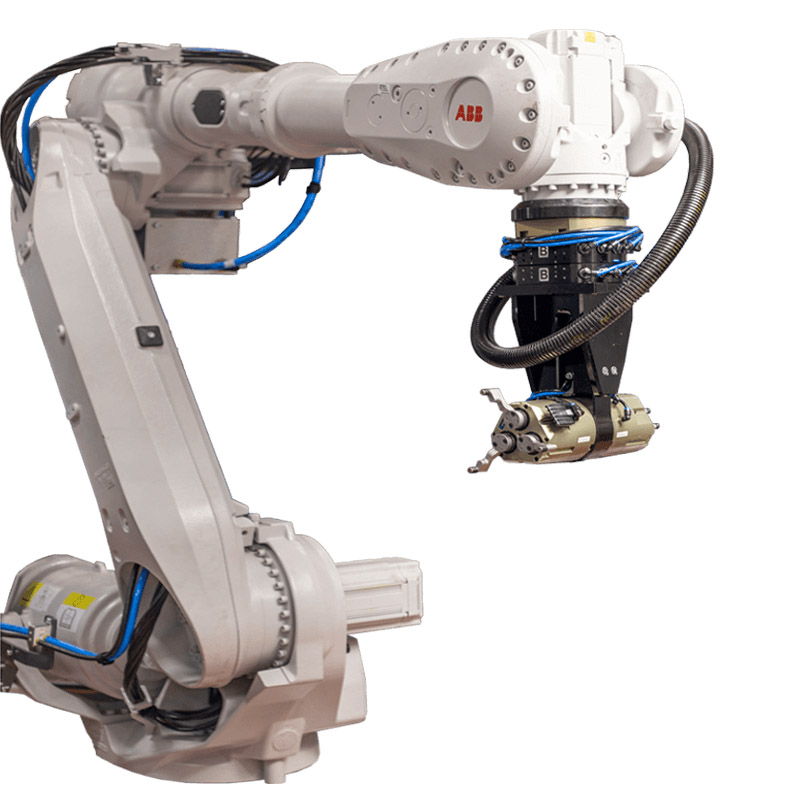

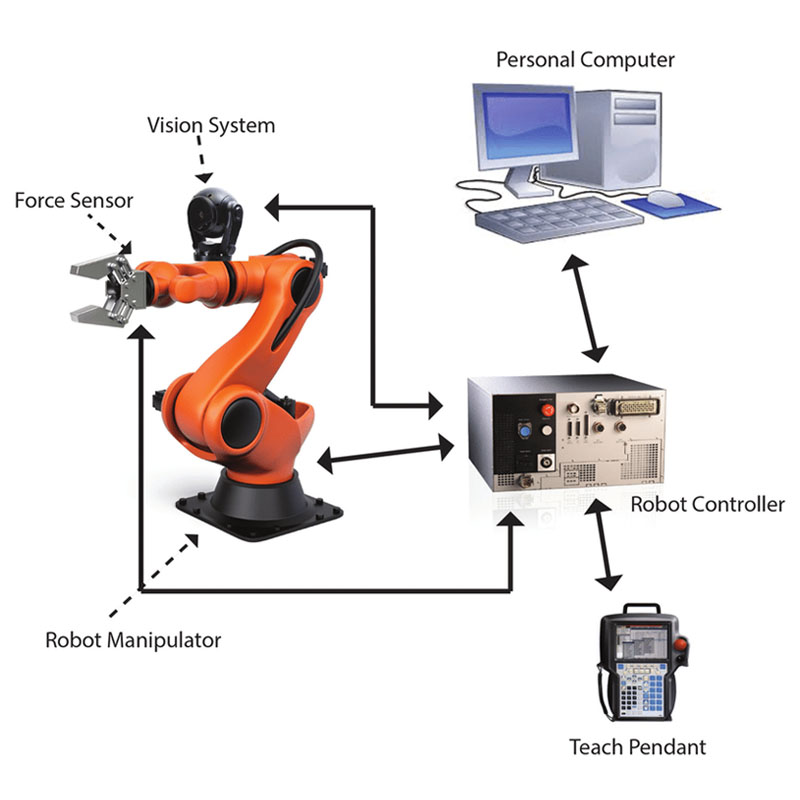

In the steel industry, the use of autonomous robots, such as the 4 Dof robotic arm from ABB, has become increasingly prevalent. These robots offer numerous advantages, including increased productivity, improved safety, and cost savings. With their ability to work tirelessly without breaks, they enhance productivity in operations. The autonomous nature of these robots also makes them ideal for performing hazardous tasks, ensuring the safety of human workers. Additionally, robotic automation companies like ABB offer competitive prices for their robotic arms, making them an attractive option for steel industry businesses looking to optimize their operations.