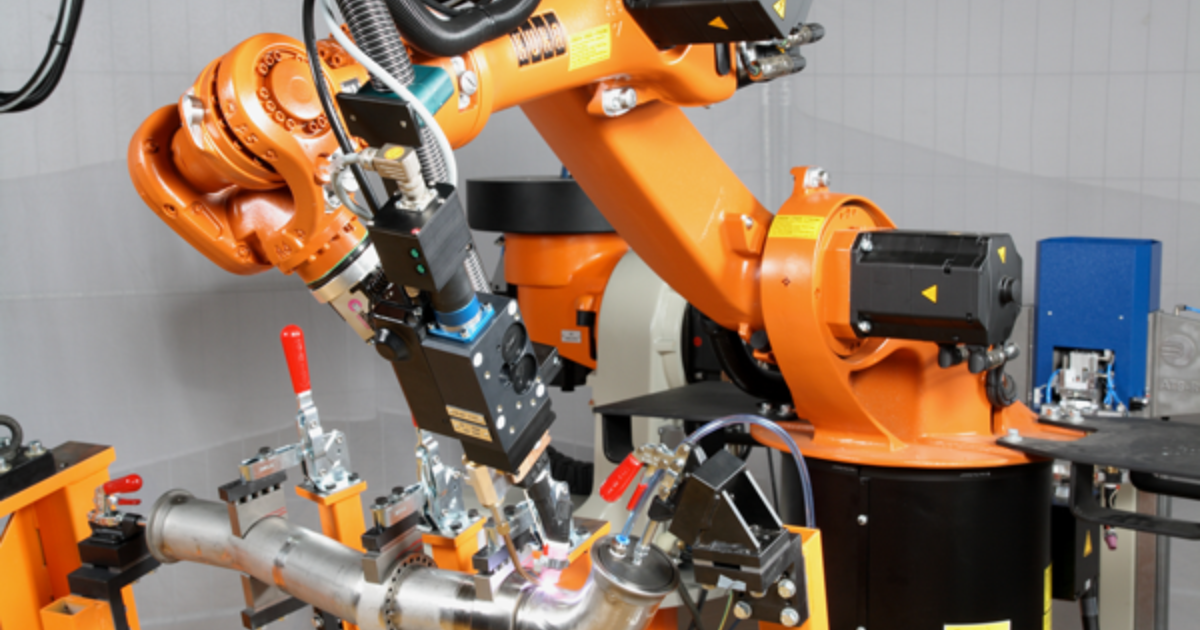

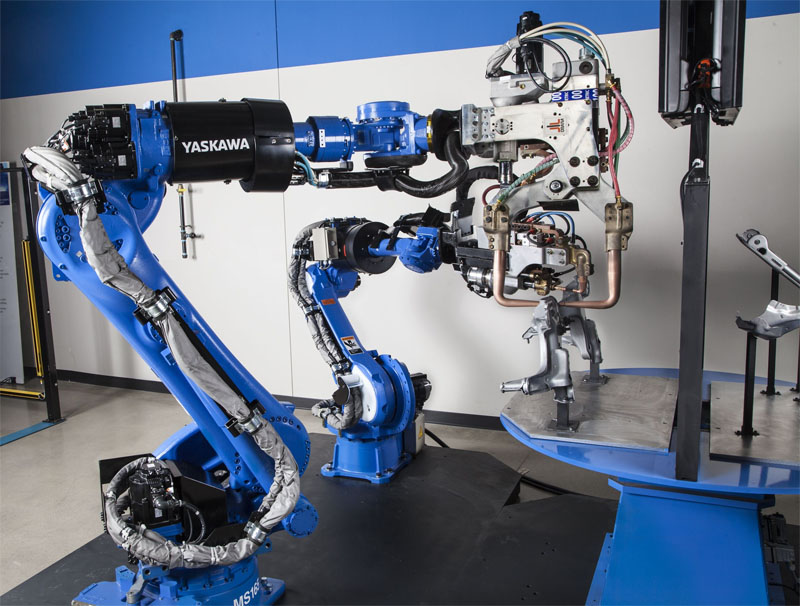

Spot Welding Robot System

Spot Welding Robot System:

1. Increased productivity: The robot system can perform spot welding tasks at a faster rate compared to manual welding, thereby increasing productivity and reducing production time.

2. Improved accuracy and consistency: The robot system ensures precise and consistent spot welds, resulting in higher quality products and reducing the need for rework.

3. Enhanced worker safety: By automating the spot welding process, the system eliminates the need for human workers to perform repetitive and potentially hazardous tasks, thereby improving worker safety.

Catalogue:

Spot Welding Robot System:

Spot Welding Robot System is a cutting-edge technology that is revolutionizing the manufacturing industry. Kuka Rsi Control, one of the top robotic companies, has developed this system to enhance productivity and efficiency. The system utilizes the Ur5 Robot Arm, which is known for its precision and versatility. With this advanced technology, manufacturers can automate the spot welding process, reducing human error and increasing production speed. Kuka Rsi Control's spot welding robot system has become a game-changer in the industry, allowing companies to streamline their operations and deliver high-quality products to their customers.