Spot Welding Robot In Use

Spot Welding Robot In Use:

There are several advantages of using a spot welding robot in industrial applications.

Firstly, spot welding robots offer high precision and accuracy, ensuring consistent weld quality and reducing the likelihood of defects or errors.

Secondly, these robots can work at a faster pace compared to human operators, resulting in increased productivity and efficiency.

Lastly, spot welding robots can operate in hazardous or challenging environments, such as high temperatures or confined spaces, ensuring the safety of human workers and reducing the risk of accidents.

Catalogue:

Spot Welding Robot In Use:

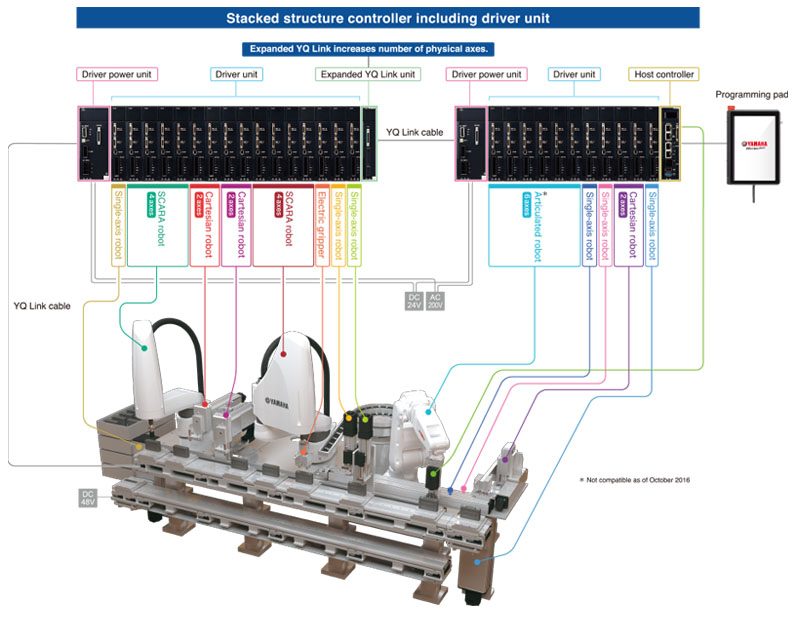

Spot welding robots are widely used in the automotive industry to join metal sheets together. These robots are equipped with special welding guns that deliver high-intensity electric current to create strong and durable welds. The robots are programmed to accurately position the welding gun and apply the correct amount of pressure and current for each weld. This automation not only improves the quality and consistency of the welds but also increases productivity and reduces labor costs.

Kuka Za Traktor Store

Kuka Za Traktor Store is a leading retailer of Kuka robotic arms specifically designed for tractors. These robotic arms are used for various tasks in agriculture, such as planting seeds, spraying pesticides, and harvesting crops. The Kuka arms are highly versatile and can be easily attached to different tractor models. They are equipped with advanced sensors and cameras to ensure precise and efficient operations. With the help of Kuka Za Traktor Store, farmers can automate their farming processes and increase productivity.

The Meca500 robot arm is a compact and lightweight robotic arm that is highly suitable for small-scale industrial applications. With its high precision and flexibility, the Meca500 can perform tasks such as assembly, pick and place, and quality inspection. Its small size allows it to be easily integrated into existing production lines, saving space and reducing costs. The Meca500 is also known for its user-friendly interface, making it easy for operators to program and control.

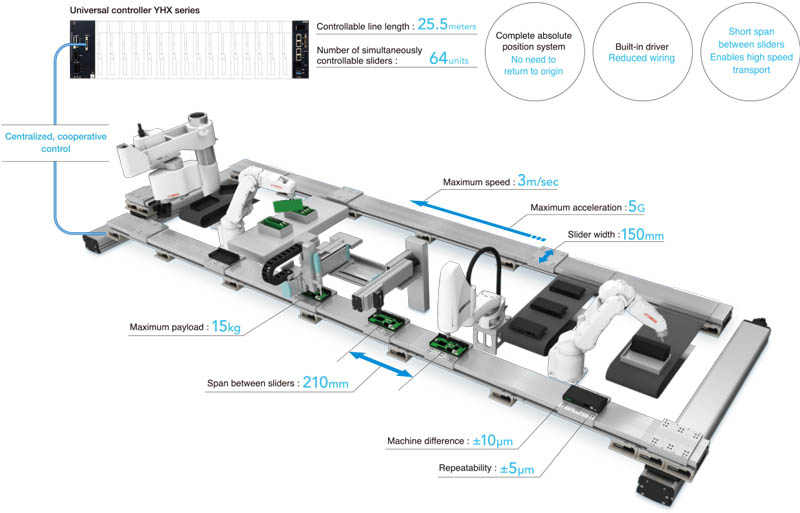

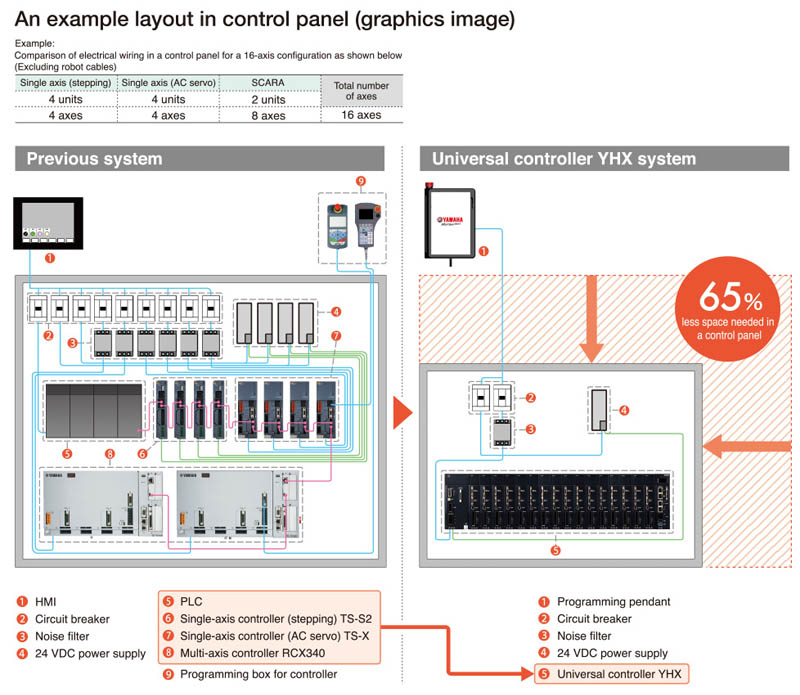

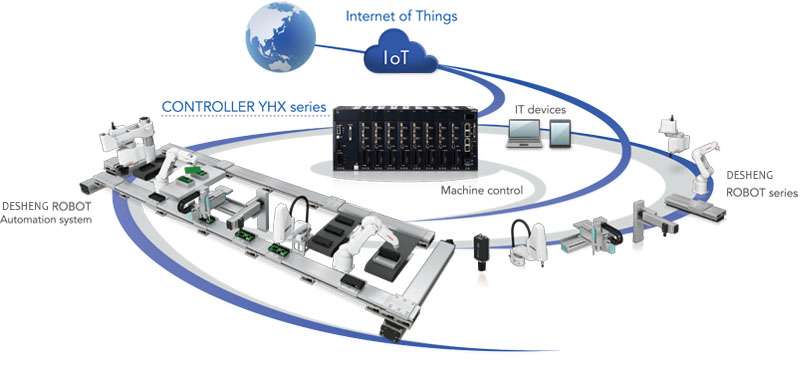

Automated robotic machinery is revolutionizing the manufacturing industry by increasing efficiency and reducing human error. These machines are equipped with advanced sensors and cameras to accurately perform tasks such as assembly, packaging, and quality control. They can work continuously without fatigue, ensuring consistent and high-quality output. Automated robotic machinery also improves workplace safety by taking over hazardous tasks and reducing the risk of accidents. With the help of these machines, manufacturers can streamline their production processes and stay competitive in the global market.