Robotic Labeling Machine Solution

Robotic Labeling Machine Solution:

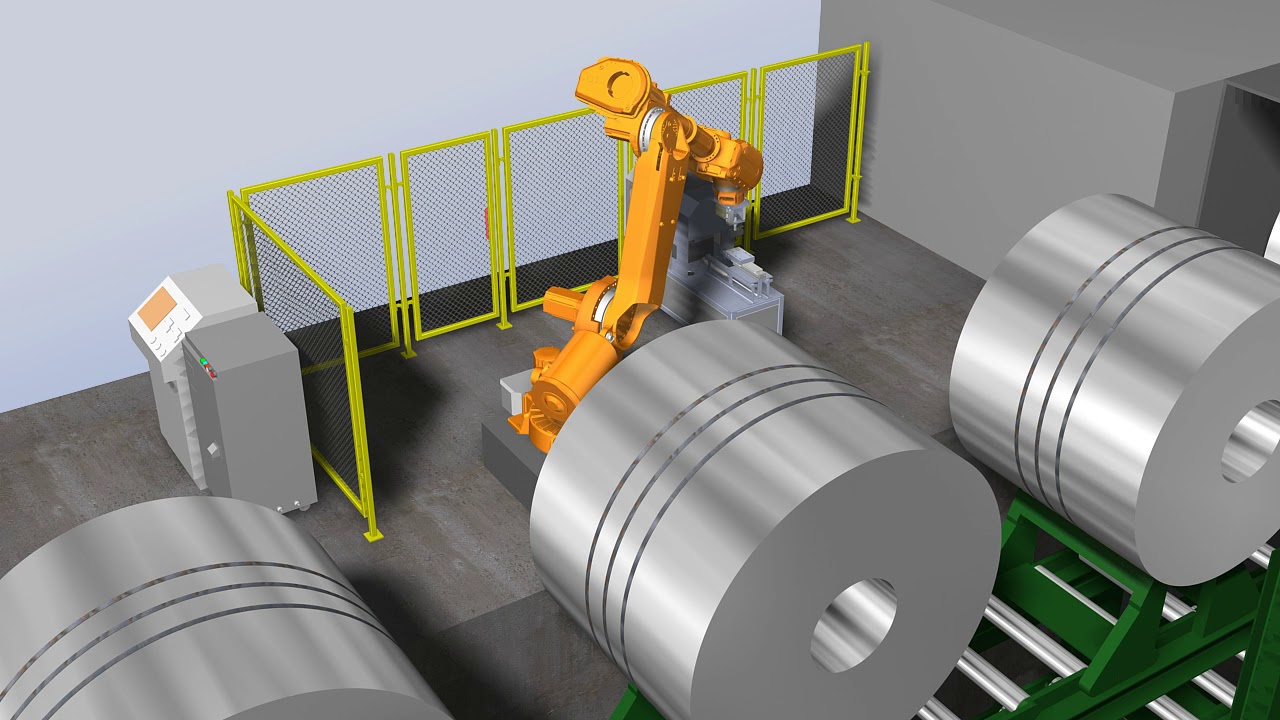

The project uses a robot plus linear ground rail moving technique.

The installation area is regarded as being at the end of the output roller table of the

Continuous casting machine for 1#. The robot is programmed to flow 1, 2, 3, 4, and 5 to the casting machine, in accordance with the production rhythm of Max60 pieces/hour. At the station, the label welding process is completed. The area of the cooling bed's receiving position has been given careful thought in this concept. The welding label machine's layout is practical, which has no bearing on the sampling inspection of the billet samples from the 1# casting machine. The sample channel is set aside to carry out the sampling process following flame cutting.

Please Contact Us For Detailed Technical Parameters.

Robotic Labeling Machine Solution:

Robotic labeling machines are revolutionizing the labeling industry with their advanced capabilities. These machines utilize robotic technology to apply labels with precision and speed, minimizing errors and increasing efficiency.

When considering the purchase of an automatic labeling machine, price is a significant factor. However, it's important to remember that the price will vary depending on the machine's features and capabilities. It's recommended to choose a machine that aligns with your specific labeling needs and budget.

For round bottle labeling, an automatic labeling machine specifically designed for round bottles is ideal. It ensures accurate application of labels on curved surfaces, enhancing your product's branding and aesthetics.

Additionally, an automatic labeling machine for sleeves offers a convenient solution for applying shrink sleeves. This machine precisely applies the sleeve to the container, providing a seamless finish and professional look.

Investing in these automatic labeling machines can greatly enhance your labeling process, improve productivity, and contribute to the overall success of your business.

1. Process requirements and technical data | |||||||||||

NO. | Item | 1# machine | |||||||||

1 | Casting machine station | 1、2、3、4、5 flow | |||||||||

2 | Diameter specification | 270、350、390、430mm | |||||||||

3 | Standard length | 5.7-9.4m | |||||||||

4 | Pull speed | 0.15-1.2m/min | |||||||||

5 | Production rhythm | 45 minutes a furnace of steel | |||||||||

6 | The temperature range of the | 550-650 | |||||||||

7 | Flow spacing | 1650mm | |||||||||

8 | Production rhythm | Max60 /hour | |||||||||

9 | Annual output | 1 million tons | |||||||||

10 | Annual production time | 350 Day | |||||||||