Robotic Automation In Manufacturing

Robotic Automation In Manufacturing:

1,Increased efficiency and productivity: Robots can work around the clock without breaks, leading to higher production rates and reduced cycle times, resulting in improved overall efficiency and productivity.

2,Enhanced quality and precision: With their precise movements and repeatable actions, robots can consistently produce high-quality products with minimal errors, reducing waste and rework.

3,Improved worker safety: By taking over hazardous tasks or heavy lifting, robots help eliminate the risk of injuries to human workers. This leads to a safer work environment and reduces workplace accidents and associated costs.

Robotic automation In Manufacturing:

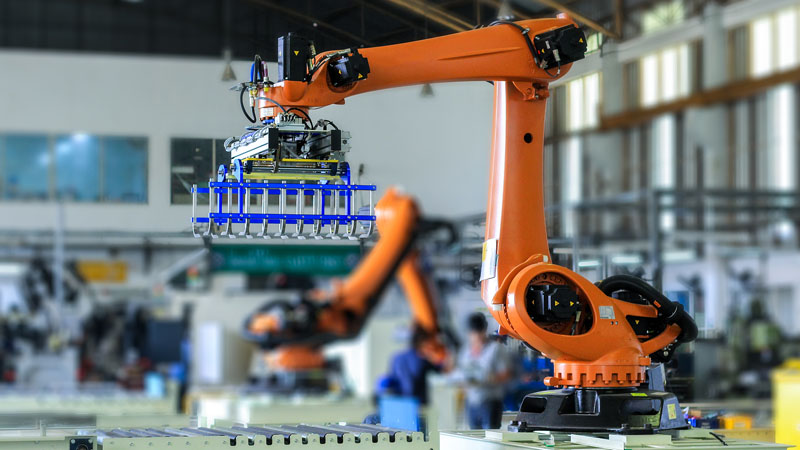

Robotic Automation in manufacturing, such as robot picking warehouse systems and retail robotics solutions, is transforming the industry. With advancements like robotic press automation, these solutions offer numerous benefits. Robotic automation in manufacturing enhances efficiency and productivity by accelerating production rates and reducing cycle times. It also ensures high-quality products through precise movements and minimizes errors. Additionally, these solutions promote worker safety by taking on hazardous tasks and eliminating the risk of injuries. Robot picking warehouse systems optimize warehouse operations by automating order fulfillment processes, improving accuracy and speed. Retail robotics solutions streamline retail operations, from inventory management to customer service, enhancing the overall shopping experience. Overall, robotic automation is revolutionizing manufacturing, delivering higher productivity, better quality, and a safer working environment.

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ||||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ABB | |||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||