Pwr Packaging With Robots

Pwr Packaging With Robots:

1,Increased efficiency and speed: Robots can perform packaging tasks at a faster pace compared to manual labor, leading to higher production rates and improved efficiency in packaging processes.

2,Improved precision and consistency: Robots are programmed to carry out packaging tasks with precision, ensuring consistent placement and alignment of products or materials. This helps maintain product integrity and reduces errors in packaging.

3,Enhanced safety and reduced labor costs: By automating packaging tasks, PWR helps create a safer working environment by eliminating the risk of injuries associated with manual labor. Additionally, the use of robots can reduce labor costs and free up human workers to focus on more complex or value-added tasks.

Pwr Packaging With Robots:

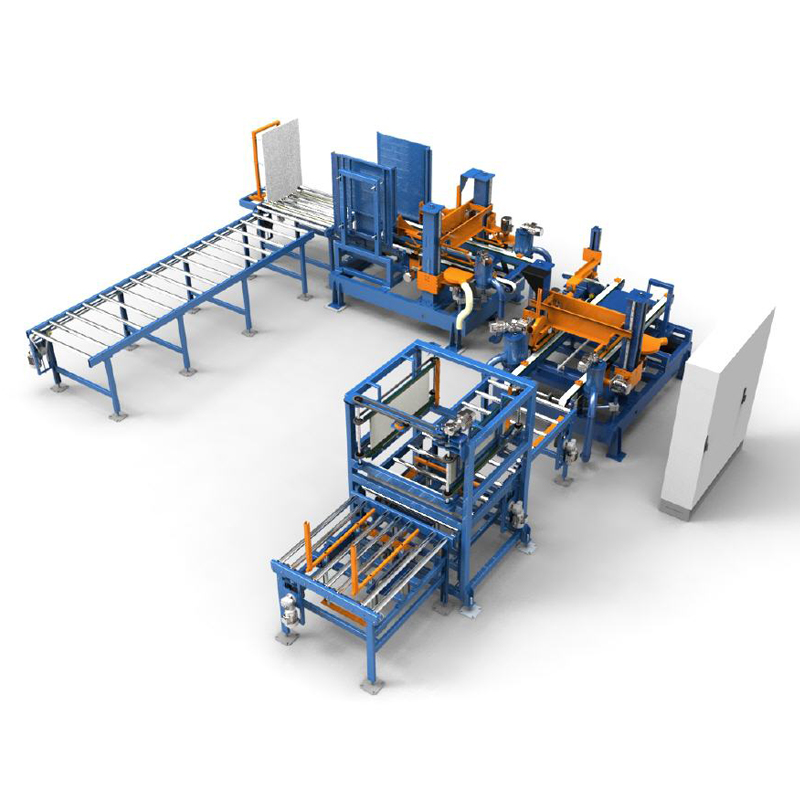

PWR Packaging With Robots combines the power of automation with packaging solutions, offering numerous benefits to industries. In the world of robotics, World Robotics Industrial Robots provide advanced automation capabilities for various applications. Octopuz Welding Software enhances welding processes by optimizing robot movements and improving efficiency. Box palletizing robots automate the labor-intensive task of stacking boxes onto pallets, saving time and reducing manual handling risks. With PWR Packaging With Robots, industries can experience increased productivity, improved precision, and reduced labor costs. By utilizing these technologies, companies can streamline their packaging operations, increase output, and ensure consistency in the packaging process. These innovative solutions revolutionize the packaging industry, bringing efficiency and automation to meet the demands of a rapidly evolving market.

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ||||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ABB | |||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||