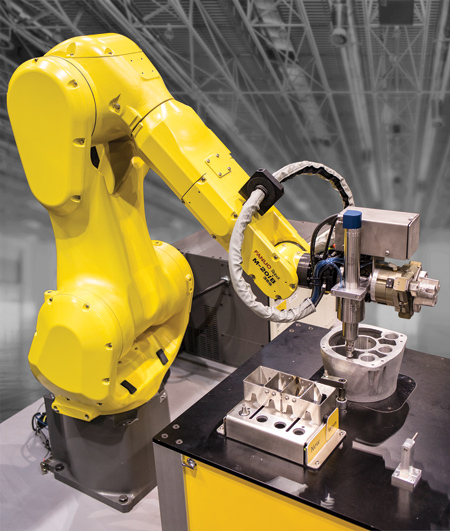

Continuous Casting-Hardness Detection Robot Solution

Continuous Casting-Hardness Detection Robot Solution:

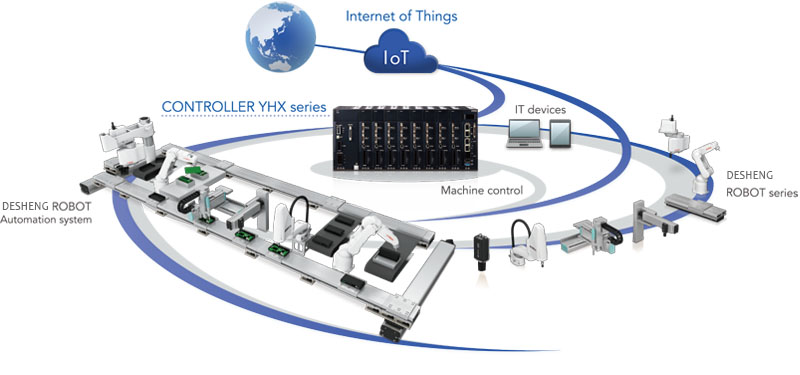

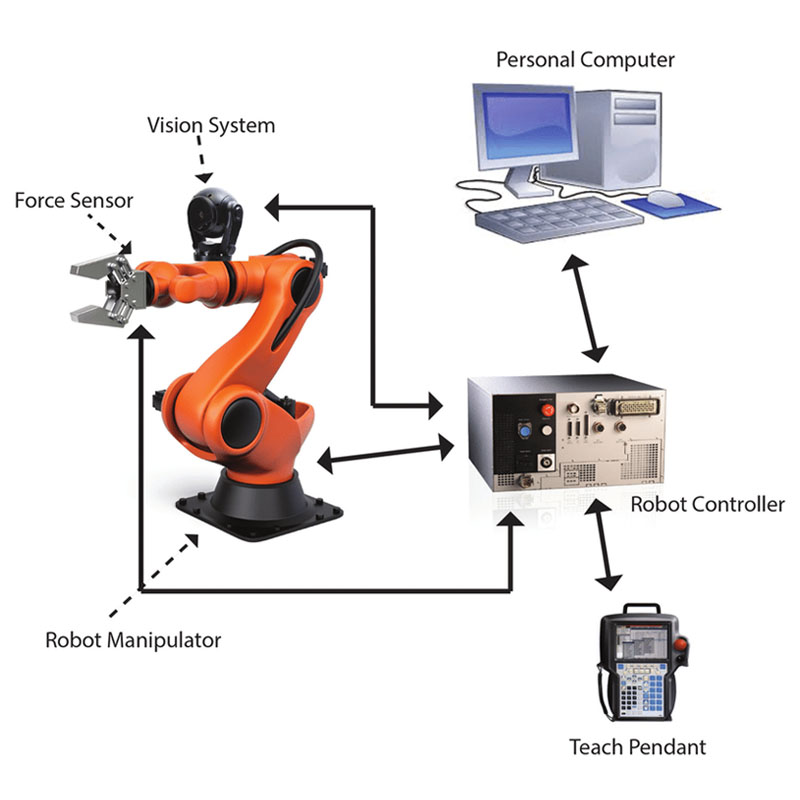

1,Accuracy: The robot utilizes advanced sensing and measurement technologies to accurately detect the hardness of continuous castings. This ensures precise and reliable results, minimizing errors and improving overall quality control.

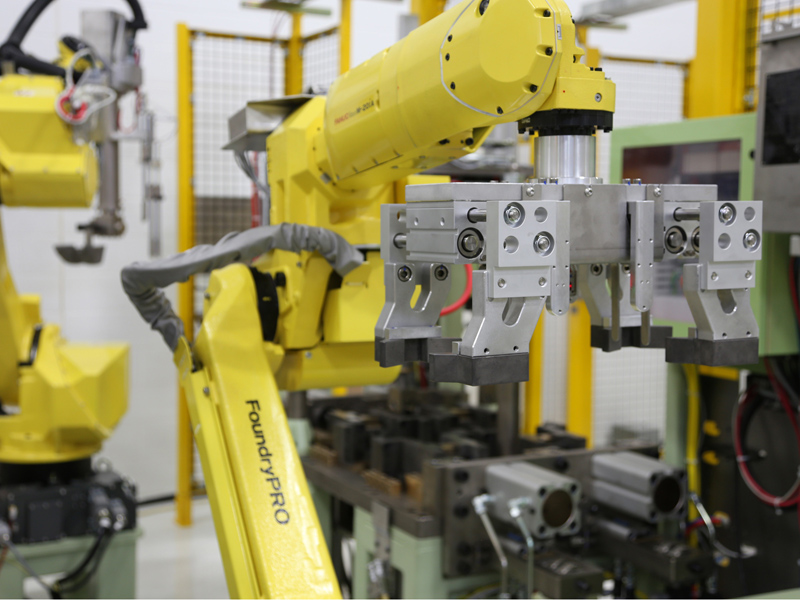

2,Efficiency: The robot operates autonomously and can continuously monitor the hardness of castings without human intervention. This significantly reduces the time and effort required for manual inspections, allowing for faster production cycles and increased productivity.

3,Safety: By eliminating the need for manual hardness testing, the robot reduces the risk of accidents and injuries associated with traditional methods. It can operate in hazardous environments, such as high-temperature areas, ensuring the safety of workers and maintaining a secure working environment.

Please Contact Us For Detailed Technical Parameters.

Continuous Casting-Hardness Detection Robot Solution:

Continuous Casting-Hardness Detection Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.

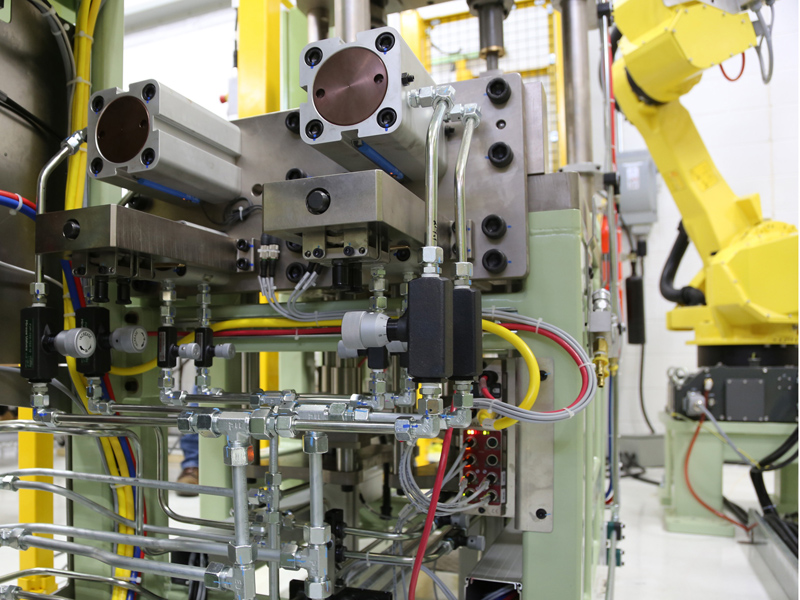

1,Steel Manufacturing: The robot is used in continuous casting processes to monitor the hardness of steel castings. It ensures that the castings meet the required specifications, preventing defects and ensuring the quality of the final product.

2,Automotive Industry: The robot is employed in the production of automotive components, such as engine blocks and transmission parts. By continuously monitoring the hardness during the casting process, it helps maintain the desired strength and durability of these critical components.

3,Aerospace Sector: The robot plays a crucial role in the production of aerospace components, such as turbine blades and structural parts. It ensures that the castings meet the stringent quality standards required for aerospace applications, guaranteeing the safety and reliability of the final products.