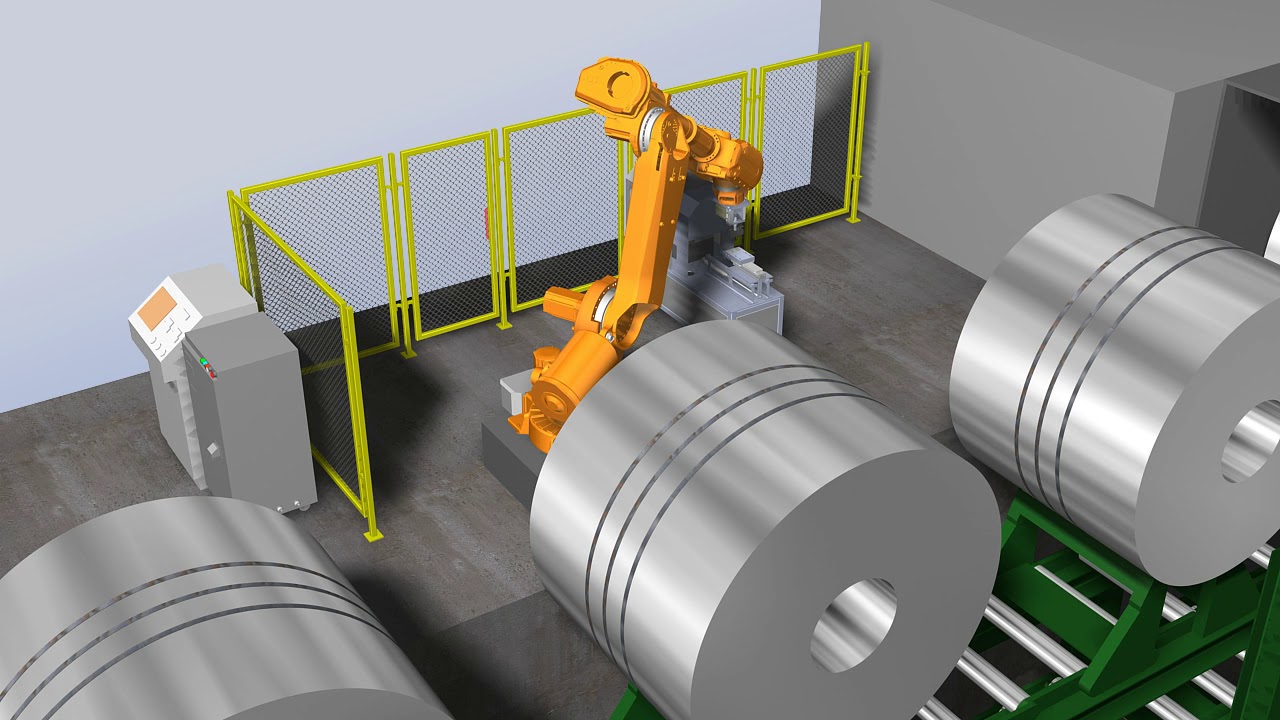

Carbon Steel Tube Labeling Robot Solution

Carbon Steel Tube Labeling Robot Solution:

The project uses the linear ground rail movement method in conjunction with a robot.

On the end of the output roller table of the installation area is considered

One-pound continuous casting machine. The robot is programmed to flow 1, 2, 3, 4, and 5 to the casting machine in accordance with a production rhythm of Max60 pieces/hour. At the station, the label welding process is performed. The area where the cooling bed would be received has been taken into account in this plan. Reasonable design decisions were made in the welding label machine's arrangement, which had no impact on the sampling inspection of the billet samples from the 1# casting machine. For the purpose of carrying out the sample process following flame cutting, the sampling channel is set aside.

Please Contact Us For Detailed Technical Parameters.

Carbon Steel Tube Labeling Robot Solution:

The carbon steel tube Labeling Robot is a reliable and durable solution for labeling tubes in various industries. With its robust construction, it ensures accurate and efficient labeling, enhancing product identification and branding.

When considering an automatic bottle labeling machine, price is a crucial factor. The cost will depend on the machine's features and capabilities, making it essential to select a machine that meets your labeling requirements and budget.

For packaging boxes, an automatic box labeling machine offers a convenient and efficient solution. It ensures precise label placement on different box sizes and shapes, streamlining the packaging process.

In industries that deal with cables and wires, an automatic cable labeling machine is indispensable. This machine can handle various cable diameters and types, providing legible and durable labeling, thereby improving organization and traceability.

Investing in these automatic labeling machines can significantly improve efficiency and productivity. Choosing the right machine for your specific labeling needs and considering the price will ensure a successful labeling process and contribute to the overall success of your business.

1. Process requirements and technical data | |||||||||||

NO. | Item | 1# machine | |||||||||

1 | Casting machine station | 1、2、3、4、5 flow | |||||||||

2 | Diameter specification | 270、350、390、430mm | |||||||||

3 | Standard length | 5.7-9.4m | |||||||||

4 | Pull speed | 0.15-1.2m/min | |||||||||

5 | Production rhythm | 45 minutes a furnace of steel | |||||||||

6 | The temperature range of the | 550-650 | |||||||||

7 | Flow spacing | 1650mm | |||||||||

8 | Production rhythm | Max60 /hour | |||||||||

9 | Annual output | 1 million tons | |||||||||

10 | Annual production time | 350 Day | |||||||||