Carbon Steel Labeling Machine Solution China

Carbon Steel Labeling Machine Solution China:

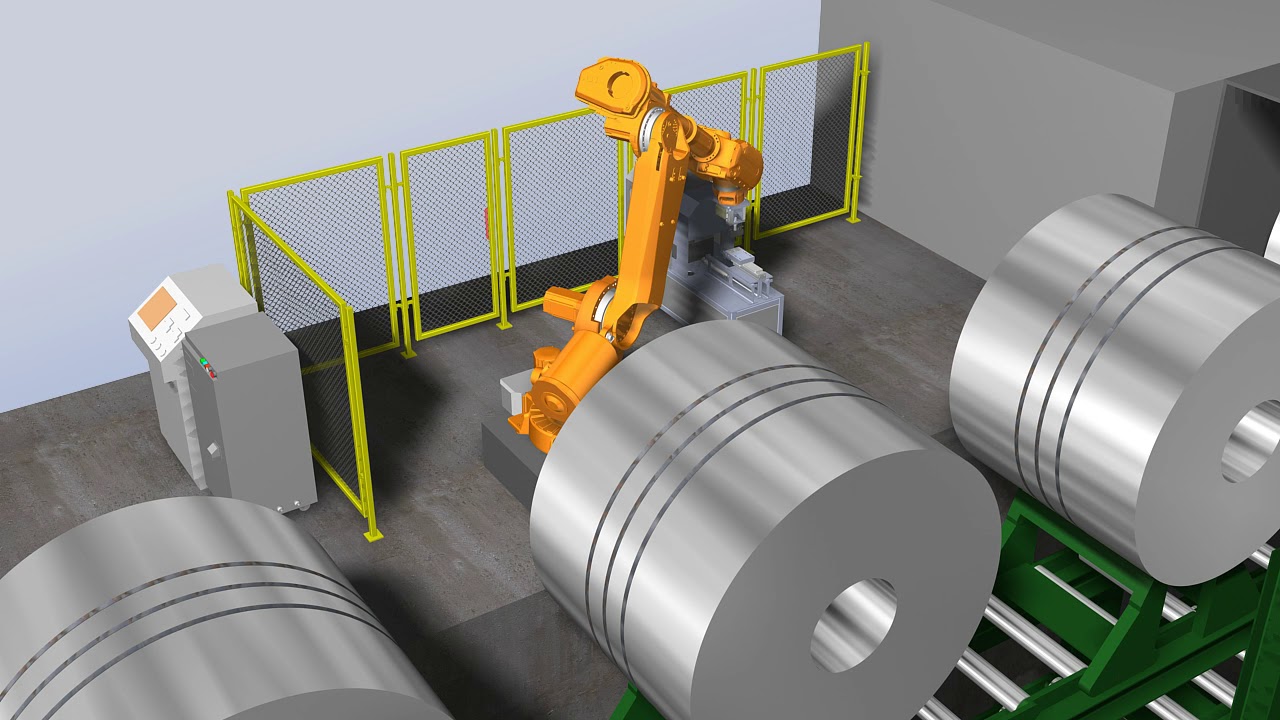

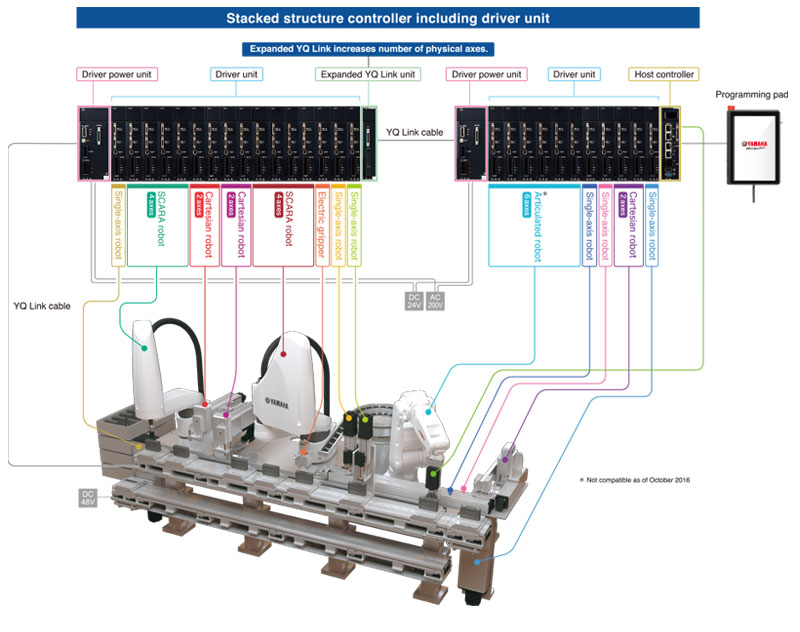

Using straight ground rails, the two robots can work independently at their

respective welding stations (1# robot is responsible for the welding operations of

the 1st and 5th stations, and 2# robot is responsible for the welding of the 2nd to

4th stations).

Please Contact Us For Detailed Technical Parameters.

Carbon Steel Labeling Machine Solution China:

China is known for its manufacturing prowess, and the carbon steel labeling machine is another example of its expertise. This durable and efficient machine is widely used in various industries. Additionally, automatic labeling machine applicators are gaining popularity for their ability to apply labels accurately and efficiently.

The demand for automatic labeling machines for bottles and boxes is also on the rise. These machines are designed to handle different shapes and sizes, providing seamless labeling solutions. With their advanced technology and user-friendly features, they have become indispensable in the packaging industry. Whether it's glass bottles or cardboard boxes, automatic labeling machines offer precise and consistent labeling, ensuring a professional look for products.

As China continues to innovate and offer high-quality automatic labeling machines, businesses around the world can benefit from these reliable and efficient labeling solutions.

1. Process requirements and technical data | |||||||||||

NO. | Item | 1# machine | |||||||||

1 | Casting machine station | 1、2、3、4、5 flow | |||||||||

2 | Diameter specification | 270、350、390、430mm | |||||||||

3 | Standard length | 5.7-9.4m | |||||||||

4 | Pull speed | 0.15-1.2m/min | |||||||||

5 | Production rhythm | 45 minutes a furnace of steel | |||||||||

6 | The temperature range of the | 550-650 | |||||||||

7 | Flow spacing | 1650mm | |||||||||

8 | Production rhythm | Max60 /hour | |||||||||

9 | Annual output | 1 million tons | |||||||||

10 | Annual production time | 350 Day 1. Process requirements and technical dataNO.Item1# machine1Casting machine station1、2、3、4、5 flow2Diameter specification270、350、390、430mm3Standard length5.7-9.4m4Pull speed0.15-1.2m/min5Production rhythm45 minutes a furnace of steel6The temperature range of thebillet at the mark550-6507Flow spacing1650mm8Production rhythmMax60 /hour9Annual output1 million tons10Annual production timeavailable350 Day | |||||||||