Carbon Steel Labeling Machine Equipment Solution

Carbon Steel Labeling Machine Equipment Solution:

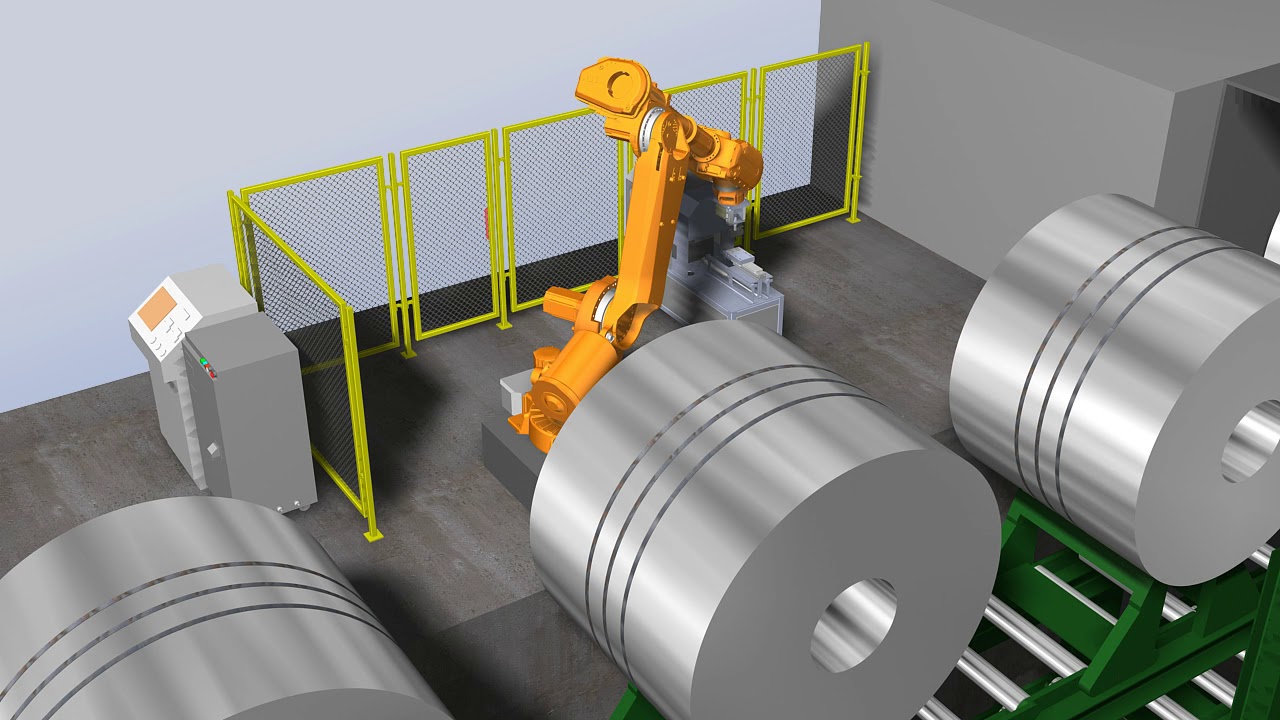

Using Kawasaki RS020N robot, load 20kg, arm span 1725mm, this model of robot

to cope with the harsh environment of the metallurgical industry, high stability, low

failure rate, can achieve the function of multi-angle free welding label. Considering

the impact of field temperature and dust, the robot is equipped with protective

armor (heat protection suit, heat insulation component), which can effectively

isolate the impact of thermal radiation generated by field temperature on the robot

system.

Please Contact Us For Detailed Technical Parameters.

Carbon Steel Labeling Machine Equipment Solution:

The carbon steel labeling machine equipment is a popular choice for industries due to its durability and reliability. It provides efficient and accurate labeling solutions for various products.

When it comes to pricing, the automatic flat labeling machine is a cost-effective option. It offers high-quality labeling for flat surfaces at a competitive price point.

For businesses in the food and beverage industry, the automatic jar labeling machine is a valuable investment. It ensures precise and consistent labeling on jars of different sizes and shapes, increasing productivity and enhancing branding.

Overall, the automatic labeling machine is an essential tool for businesses across various sectors. It streamlines the labeling process, reduces human error, and improves efficiency. With a wide range of options available, companies can find the perfect labeling machine to meet their specific requirements.

1. Process requirements and technical data | |||||||||||

NO. | Item | 1# machine | |||||||||

1 | Casting machine station | 1、2、3、4、5 flow | |||||||||

2 | Diameter specification | 270、350、390、430mm | |||||||||

3 | Standard length | 5.7-9.4m | |||||||||

4 | Pull speed | 0.15-1.2m/min | |||||||||

5 | Production rhythm | 45 minutes a furnace of steel | |||||||||

6 | The temperature range of the | 550-650 | |||||||||

7 | Flow spacing | 1650mm | |||||||||

8 | Production rhythm | Max60 /hour | |||||||||

9 | Annual output | 1 million tons | |||||||||

10 | Annual production time | 350 Day | |||||||||