Billet Labeling Robot Solution

Billet Labeling Robot Solution:

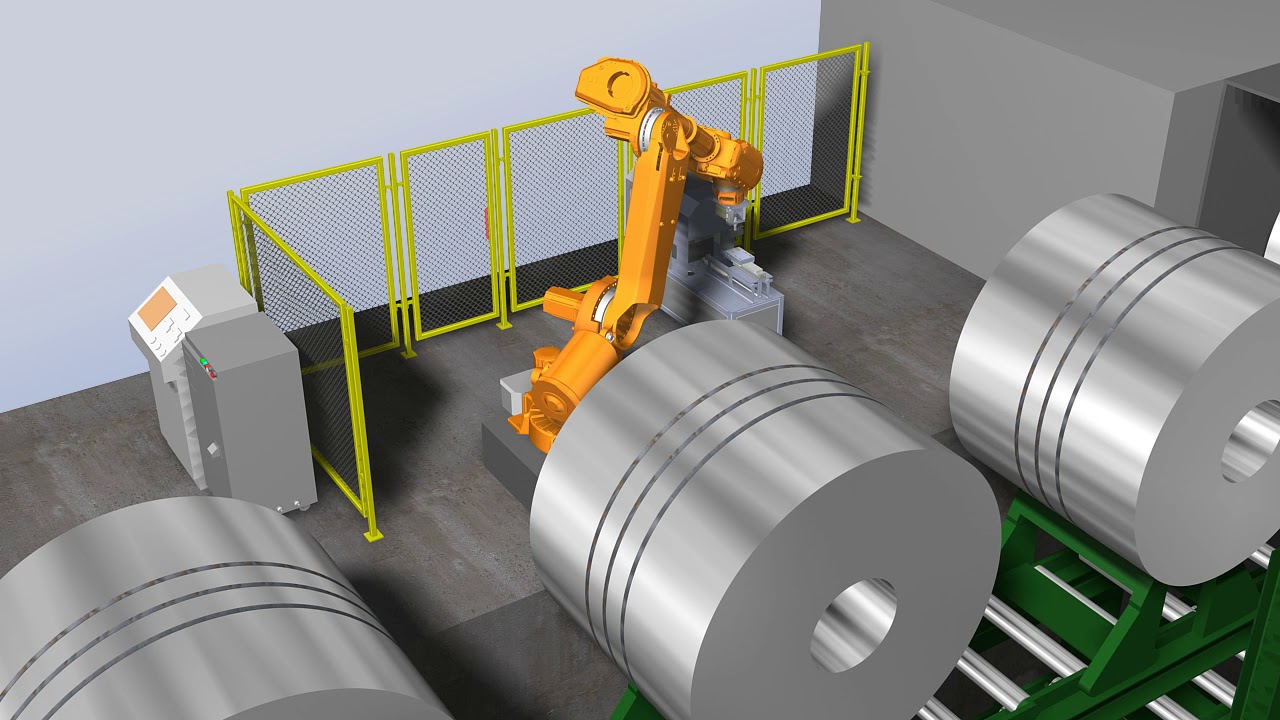

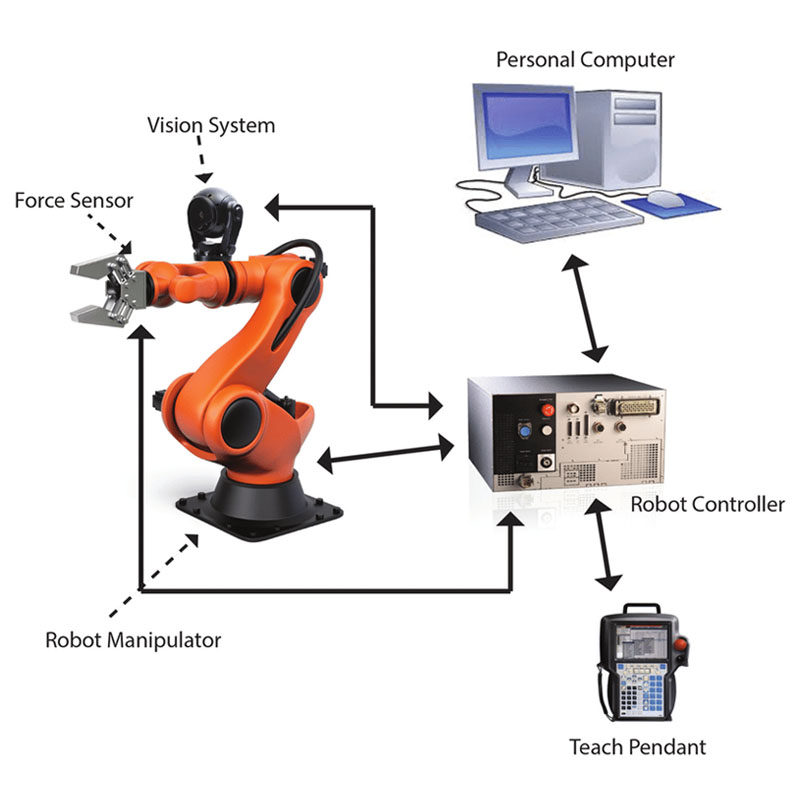

In the project, the method of robot plus linear ground rail movement is adopted.

The installation area is considered at the end area of the output roller table of the

1# continuous casting machine. According to the production rhythm of Max60

pieces/hour, the robot is set to flow 1, 2, 3, 4, and 5 to the casting machine. The

label welding operation is carried out at the station. This plan has fully considered

the space of the receiving position of the cooling bed. The layout of the welding

label machine is reasonable, which does not affect the sampling inspection of the

1# casting machine billet samples. The sampling channel is reserved to realize the

sampling operation after flame cutting.

Please Contact Us For Detailed Technical Parameters.

Billet Labeling Robot Solution:

The Billet Labeling Robot is a state-of-the-art machine that revolutionizes the labeling process for billets in the manufacturing industry. With its advanced technology, it delivers precise and efficient labeling, optimizing productivity and ensuring accurate identification.

When it comes to customs, the HS code for an Auto Labeling Machine is an important classification code. This code helps with international trade documentation and tariff classification, ensuring compliance with customs regulations.

Auto Labeling Machine Learning is an innovative feature that enables machines to learn and adapt to different labeling requirements. With machine learning capabilities, these machines can improve accuracy and efficiency over time, enhancing labeling processes.

The Automated Labeling Robot is a versatile solution that is capable of handling various labeling tasks. Equipped with cutting-edge technology, it streamlines operations, reduces errors, and increases productivity, making it a valuable addition to industries requiring automated labeling.

Investing in these automated labeling solutions can significantly transform the efficiency and accuracy of labeling processes. With technological advancements and the ability to learn, these machines are at the forefront of optimizing labeling operations in various industries.

NO. | Item | 1# machine | |||||||||

1 | Casting machine station | 1、2、3、4、5 flow | |||||||||

2 | Diameter specification | 270、350、390、430mm | |||||||||

3 | Standard length | 5.7-9.4m | |||||||||

4 | Pull speed | 0.15-1.2m/min | |||||||||

5 | Production rhythm | 45 minutes a furnace of steel | |||||||||

6 | The temperature range of the | 550-650 | |||||||||

7 | Flow spacing | 1650mm | |||||||||

8 | Production rhythm | Max60 /hour | |||||||||

9 | Annual output | 1 million tons | |||||||||

10 | Annual production time | 350 Day | |||||||||