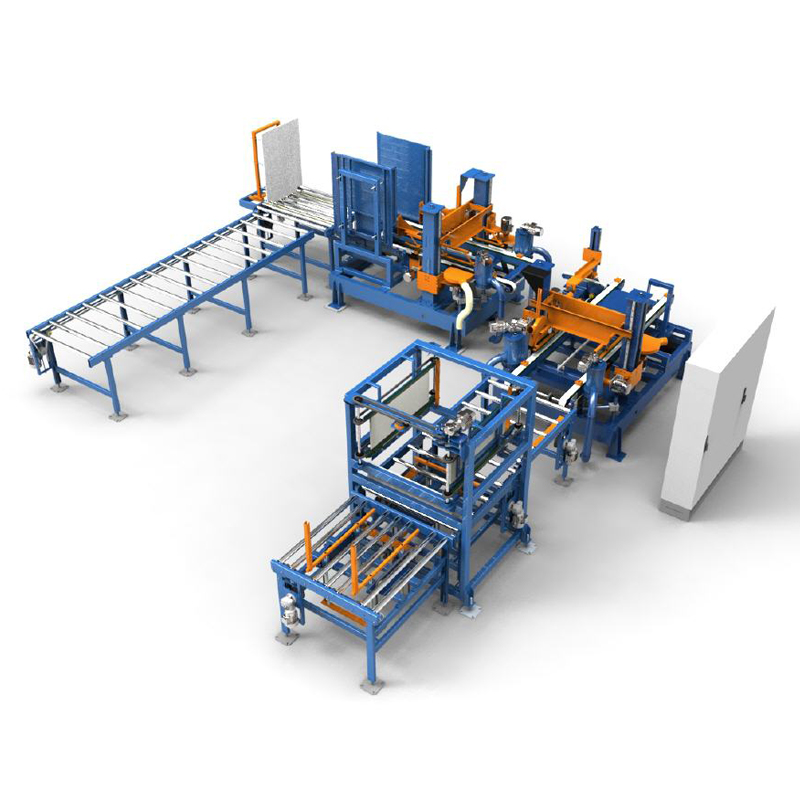

Automated Palletizing Robot

Automated Palletizing Robot:

1,Increased efficiency: The robot can work at a faster pace compared to manual palletizing, resulting in higher productivity and throughput. It eliminates the need for breaks or shifts, allowing for continuous operation.

2,Improved accuracy: The robot can precisely stack items on a pallet with consistent placement and alignment. This ensures that the load is stable and secure during transportation, reducing the risk of damage and the need for manual adjustments.

3,Enhanced safety: By automating the palletizing process, workers are freed from the physical strain of lifting heavy loads. This reduces the risk of injuries and creates a safer work environment. Additionally, the robot is equipped with safety features, such as sensors or barriers, that prevent accidents and ensure the well-being of operators.

Automated Palletizing Robot:

Automated Palletizing Robot, such as Yaskawa Industrial Automation's Palletizing Robot for Boxes, offered by Automation Robotics and Controls Inc, brings numerous advantages to the palletizing process. These robots significantly increase efficiency by operating at a faster pace, without the need for breaks or shifts. With precise stacking capabilities, the robot ensures accurate placement and alignment of items on the pallet. Moreover, this technology enhances safety by reducing the strain on workers, while also incorporating safety features to prevent accidents. Overall, Automated Palletizing Robots provide a reliable solution for efficient and safe palletizing operations.

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s Per Cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons,Cases,Bags, Pouch Bags | Containers,Bottles,Cans,Buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | Sick | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEW | |||

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s Per Cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons,Cases,Bags, Pouch Bags | Containers,Bottles,Cans,Buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | Sick | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEW | |||