Automated Car Assembly Line

Automated Car Assembly Line:

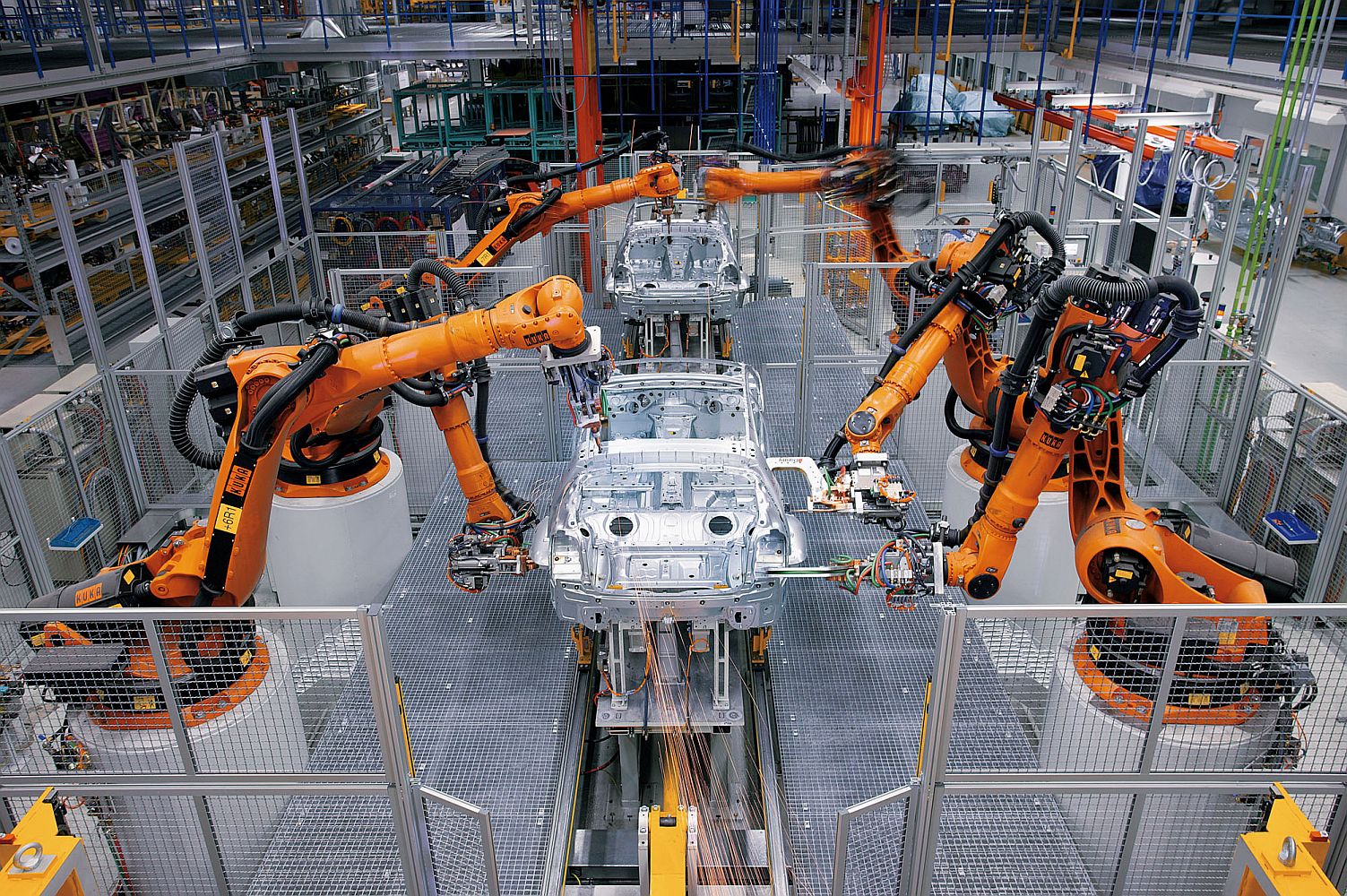

Automated Car Assembly Line has several advantages that enhance efficiency and productivity in the manufacturing process. Firstly, it significantly reduces labor costs by replacing manual tasks with automated systems, leading to higher operational cost savings. Secondly, it ensures consistent quality control as machines perform tasks with precision and accuracy, minimizing human error. Lastly, it speeds up the production cycle with faster and more efficient processes, increasing overall output and meeting customer demands in a timely manner. Overall, the Automated Car Assembly Line streamlines operations, improves quality, and boosts productivity, making it a valuable asset for car manufacturing companies.

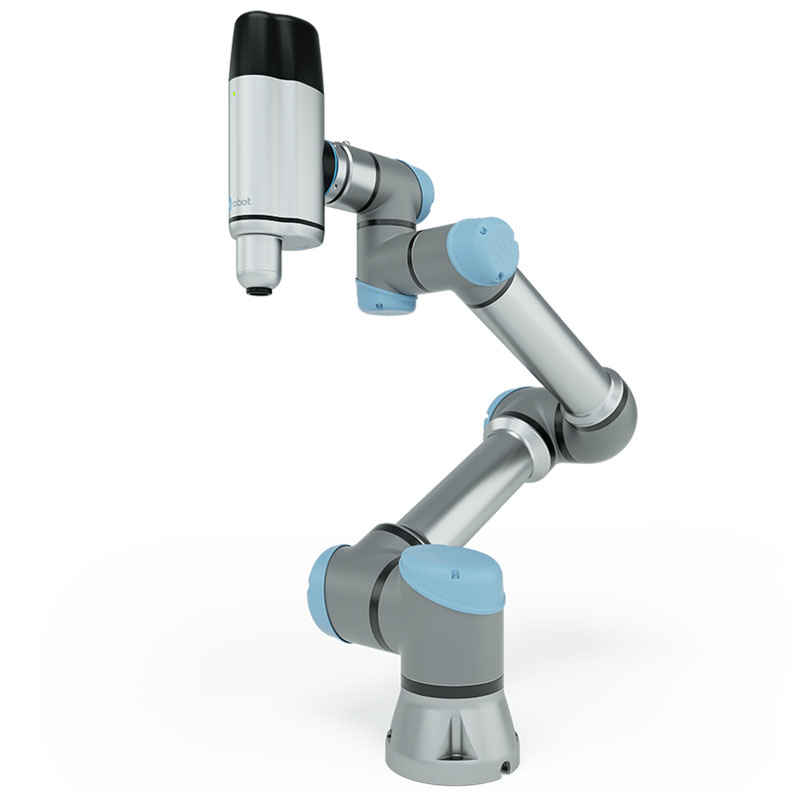

Automated Car Assembly Line, Kuka Youbot Arm, Abb Yumi Robot Manual, and Joseph Engelberger Robots are significant advancements in industrial robotics. The assembly line streamlines car manufacturing, reducing costs and improving efficiency. The Kuka Youbot Arm performs various tasks with precision. Abb Yumi Robot Manual enhances productivity and safety through collaboration. Joseph Engelberger Robots honor a pioneer in robotics, shaping the future of automation. These innovations continue to revolutionize industries, boosting productivity and driving progress.