Structural Design Engineer Aerospace

1,Small and flexible layout with 1.8m wingspan for versatile installation. Optimal maneuverability in tight and unconventional spaces.

2,High-speed and accurate with broad application range. Ideal for welding, spraying, loading, unloading, managing, sorting and assembly in commercial settings.

3,Robust emergency stop system with independent board, safety relay and double-circuit. Ensures high reliability and safety when working with heavy machinery.

4,Designed for durability in tough environments, the robot cable is high-bendy and flexible. Suitable for engineering design, laser and MIG welding. Achieve optimal performance with Air Products Argoshield.

Structural Design Engineer Aerospace:

The field of aerospace design requires skilled professionals who understand the nuances of structural design. That's why having a Structural Design Engineer Aerospace is essential for businesses looking to take on projects in this field. They can help ensure that designs are optimized for safety and efficiency.

But having a good design is only half the battle. Welding is also an important part of aerospace manufacturing. Finding Welding Shops Near Me that specialize in aerospace welding can be critical in producing high-quality final products. AWS D17 1 lays out guidelines for welding in the aerospace industry, so it's important for welders to be familiar with these standards.

To achieve optimal welding results in aerospace manufacturing, it's critical to have reliable equipment. The Lincoln Weld Pak HD is a popular choice for welding enthusiasts. Its compact size and portability make it perfect for projects where space is at a premium, while still providing the necessary power to get the job done.

When welding in the aerospace industry, safety is paramount. Accidents can be prevented by using equipment that meets industry standards and by following proper procedures. In case of an unexpected emergency, a robust emergency stop system can make a big difference. That's why it's important to carefully evaluate machines and systems, such as those with an independent board, safety relay, and double-circuit like the ones found in this robot.

With the right equipment, personnel, and processes in place, businesses can achieve success in the aerospace industry.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

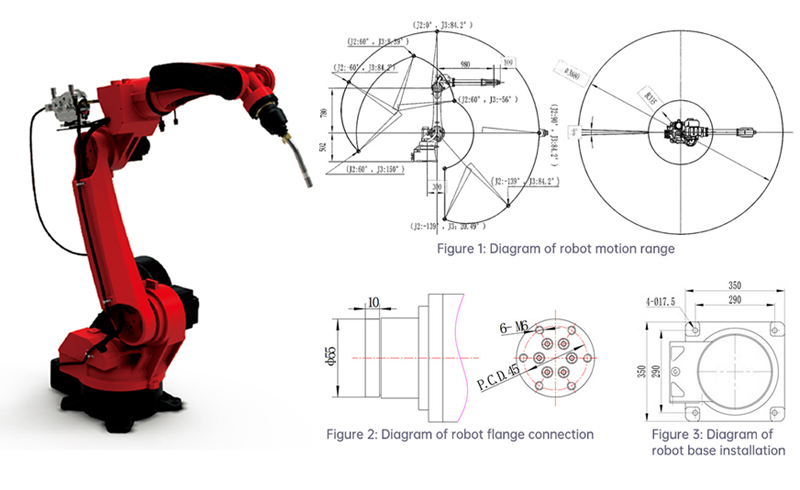

DIMENSIONAL DRAWINGS:

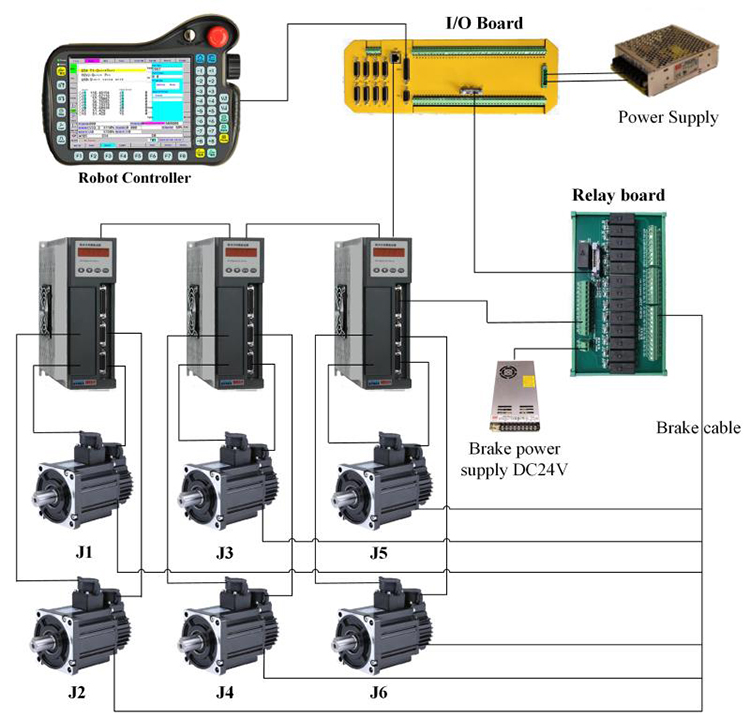

ROBOT CONTROLSYSTEM:

ADVANTAGE:

1,Free Saving

May be operated 24 hours, effec-tively shop labor prices. in additionthe use of commercial manipulator operation mode, automatic assembly line to save the web page, sothat the entire plant planning extra compact.

2,Excessive Manufacturing Performance

Manipulator manufacturing of a producttime is constant within the equal manufacturing cycle, the output is fixed product yield is excessive, excessive production advantages.

3,Excessive Balance

Manufacturing operation, high precision,high stability,can guarantee character-nel,in preference to guide risky operations.

4,Wide Utility Range

It is appropriate for hardware system-ing, automobile add-ons,furni-ture accessories, heating pipewelding embedded parts, and so on.

FEATRUES:

1,Help as plenty as 12 axis control, realizes the manipulate of outside axes (journeying axes and positioner).

2,Structural optimization set of rules suitable for the body manipulate of numerous varieties of structure.

3,Open structure for synchronization of global era and extension of features.

4,Software software functions facilitate common sense control. technique features make programming easy.

5,Modular setting of functions appropriate for severa packages. safety module guarantees cozy manufacturing of the robots.

6,Suitable for a couple of increments; absolute servo. advanced pc bus connection ensures reliability and practicability.

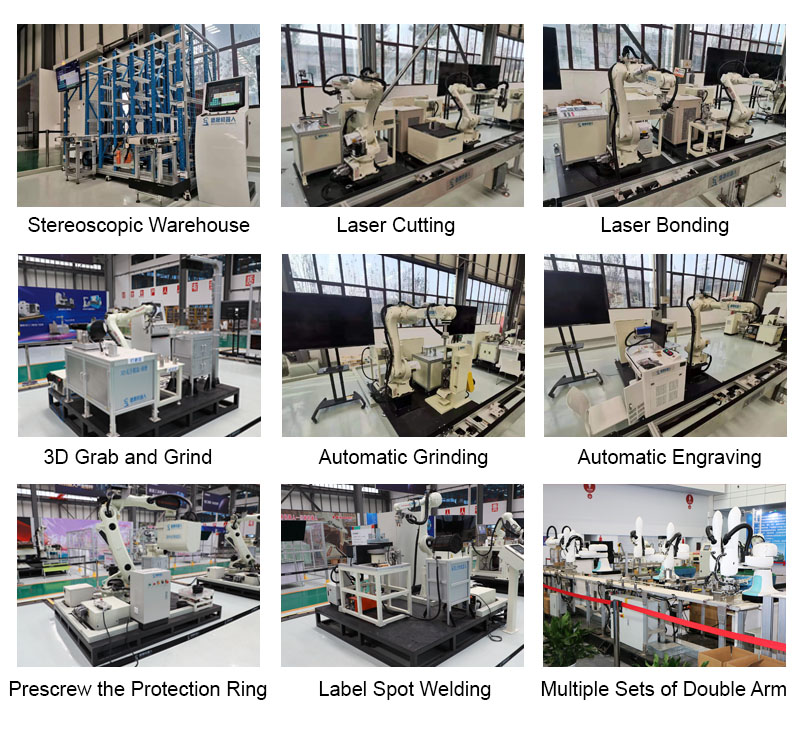

APPLICATIONS:

1, Manufacturing line, and vehicle elements production. the pocket book area calls for coordination a number of the positioner and welding robotic to advantage computerized welding, with seamless motion that meets the welding track, velocity, and gun role requirements.

2, The welding robot manufacturing reduces manpower fees and improves performance thru connecting workpiece conveying traces to form a production line.

3, Car factors production extensively benefits from welding robots, specifically within the automobile chassis welding device, wherein welding robotic modified earlier operations, enhancing each welding brilliant and operation time.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: