Robotic Process Automation Services

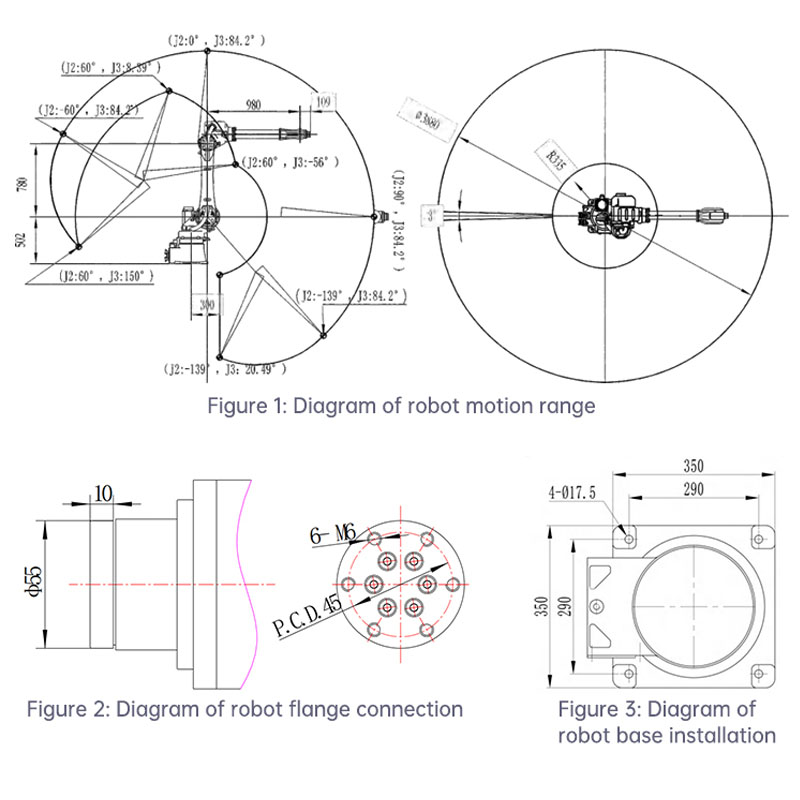

1,Nearly 1.8 meters is the wingspan. the design is extremely small and bendy for placement on the ground or upside-down installation.

2, Big running space, speedy walking speed, high repeat positioning accuracy, suitable for welding, spraying, loading and unloading, dealing with, sorting, assembly and other applications, with a extensive variety of packages.

3, Geared up with a safety emergency forestall board impartial of the control device, adopts a protection relay circuit, and gives external double-circuit emergency stop to make certain the reliability of the emergency stop.

4, The main frame cable adopts excessive-bendy robotic unique cable.

Robotic Process Automation Services:

Robotic Process Automation Services offer cutting-edge automation solutions to businesses of all sizes. With advanced technology, these services can automate repetitive and time-consuming tasks, freeing up human resources for more important work.

Aluminium Mig Welding Amperage is an important factor to consider when welding with aluminium. It determines the heat that is applied to the metal and affects the overall quality of the weld. Additionally, Air Pressure Welding Machines can help improve weld quality by providing a constant pressure and reducing the risk of errors.

For companies looking to purchase welding equipment on a budget, there are many high-quality Used Mig Welders For Sale. These machines offer a cost-effective solution for businesses looking to expand their welding capabilities without breaking the bank.

Overall, by leveraging technology and carefully selecting equipment, businesses can improve their efficiency and profitability.

PARAMETERS:

Name | ||||||||

Type | Vertical joint 6 degrees | |||||||

The main purpose | Laser Weld | |||||||

specification | DS10iG-14 | |||||||

Maxload weight | 10KG | |||||||

Position repeatability | 0.05mm | |||||||

Vibration | s4.9m/S | |||||||

Body weight | 149KG | |||||||

Maximum reach | 1566mm | |||||||

Conditions | 0-45RC,10-80%RH(no condensation) | |||||||

Protection class | Equivalent to lP65 | |||||||

Installation | Ground, hoisting side mounting | |||||||

Range | basic | J1 | ±170° | Max | basic | J1 | 173.6°/S | |

J2 | +90°-160 | J2 | 138.8°/S | |||||

J3 | +115°-90 | J3 | 198.3°/S | |||||

arm | J4 | ±190° | arm | J4 | 288.1°/S | |||

J5 | ±140° | J5 | 400°/S | |||||

J6 | ±360° | J6 | 588.2°/S | |||||

DIMENSIONAL DRAWINGS:

robot CONTROLSYSTEM:

FEATRUES:

1,Assist up to 12 axis manipulate, realizes the manipulate of outside axes (touring axes and positioner).

2,Structural optimization algorithm appropriate for the frame manipulate of diverse sorts of structure.

3,Open structure for synchronization of worldwide generation and extension of capabilities.

4,Software functions facilitate good judgment manage. method features make programming easy.

5,Modular placing of capabilities appropriate for numerous packages. safety module guarantees safe production of the robots.

6,Appropriate for a couple of increments; absolute servo. advanced laptop bus connection ensures reliability and practicability.

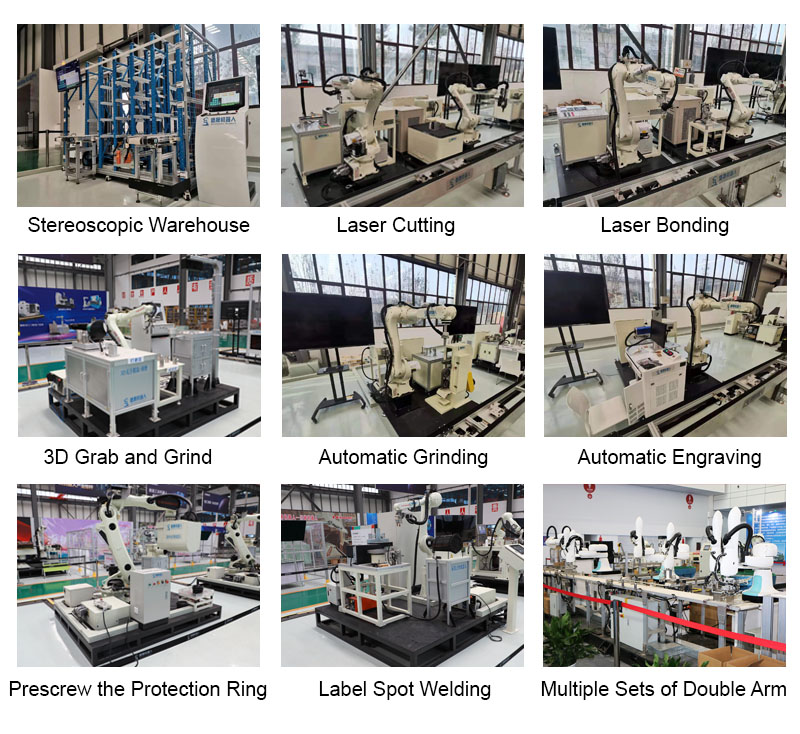

APPLICATIONS:

1, Manufacturing line, and vehicle parts manufacturing. the notebook field calls for coordination among the positioner and welding robotic to achieve computerized welding, with seamless movement that meets the welding track, speed, and gun role necessities.

2, The welding robotic manufacturing reduces manpower expenses and improves efficiency by means of connecting workpiece conveying traces to form a manufacturing line.

3, Automobile elements production distinctly advantages from welding robots, especially within the car chassis welding procedure, where welding robot replaced in advance operations, improving each welding quality and operation time.

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: