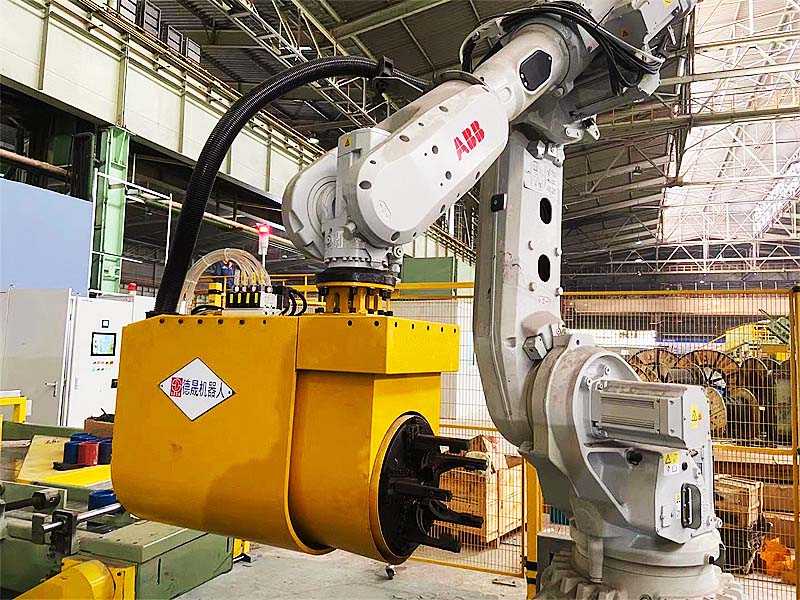

Robotic Mig Welding Machine

With the development of electronic technology, computer technology, numerical control and robotics, automatic welding robot, its technology has been increasingly mature, mainly has the following advantages:

1) Stabilize and enhance welding performance, which may be quantified numerically;

2) Increase labor output;

3) Increase the workers' productivity intensity, so that they can work in harmful environments;

4) Lowered the bar for operating competence requirements for employees;

5) Shorten the preparation period of product transformation and replacement, and reduce the corresponding equipment investment.

Robotic Mig Welding Machine:

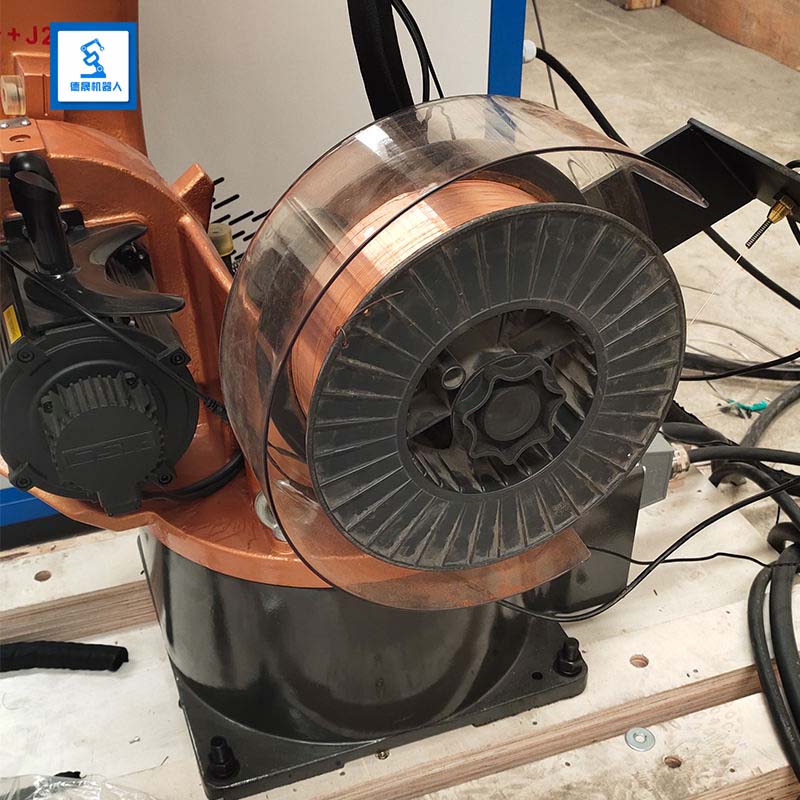

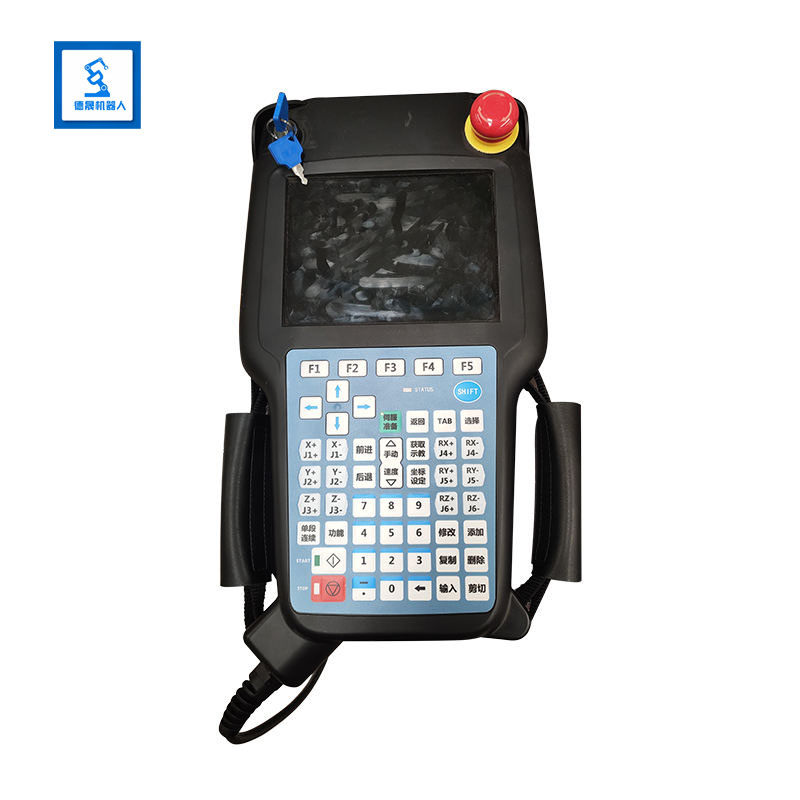

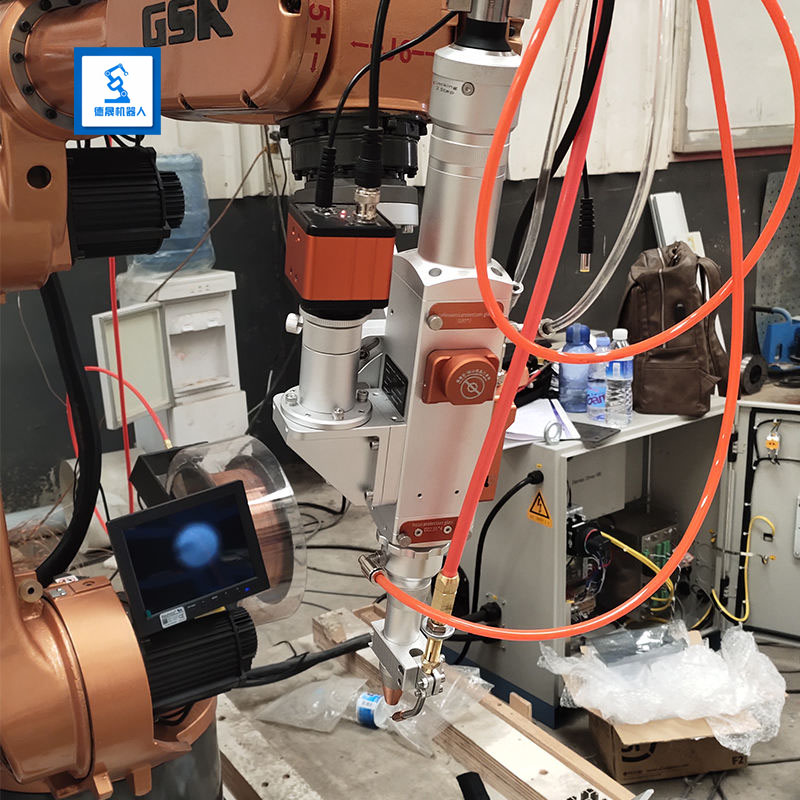

Robotic Mig Welding Machine is engaged in welding (including cutting and spraying) industrial robots. According to the definition of an industrial robot belonging to a standard welding robot adopted by the International Organization for Standardization (ISO), an industrial cobot welding robot is a multi-purpose, reprogrammable automatic control Manipulator with three or more programmable axes for use in the field of industrial automation. To suit different uses, the mechanical interface of the last shaft of the robot, usually a connecting flange, can be fitted to different tools or end-effectors. The welding robot is installed in the final shaft flange of the industrial robot welding pliers or welding (cutting) gun, so that it can be welding, cutting or thermal spraying. Welding automation robot mainly includes robot and welding equipment two parts.

Parameter:

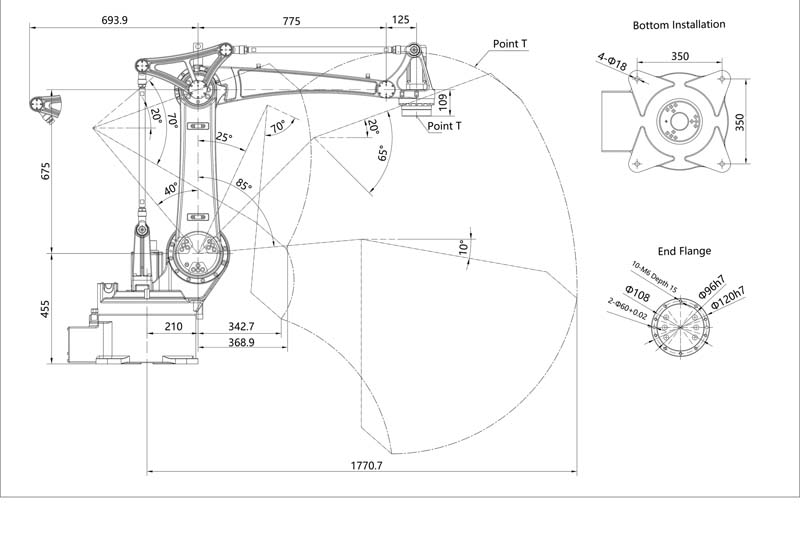

Model | PY10-1440 | |

Axis | 6 axis | |

Reach(mm) | 1440 | |

Max payload | 10KG | |

Protection Class | IP67 | |

Mounting type | Floor type/bracket type | |

Power Capacity | 4.5KVA | |

Input / output signal | 24VDC | |

Voltage | 350A/500A | |

Robot Weight | 176KG | |

Repeatability | ±0.05mm | |

Motion Range | J1 | ±160° |

J2 | +80°~-145° | |

J3 | +140°~-75° | |

J4 | ±190° | |

J5 | +50°~-210° | |

J6 | ±360° | |

Motion Speed | J1 | 199.5°/s |

J2 | 159.3°/s | |

J3 | 199.5/s | |

J4 | 392°/s | |

J5 | 272°/s | |

J6 | 1000°/s | |

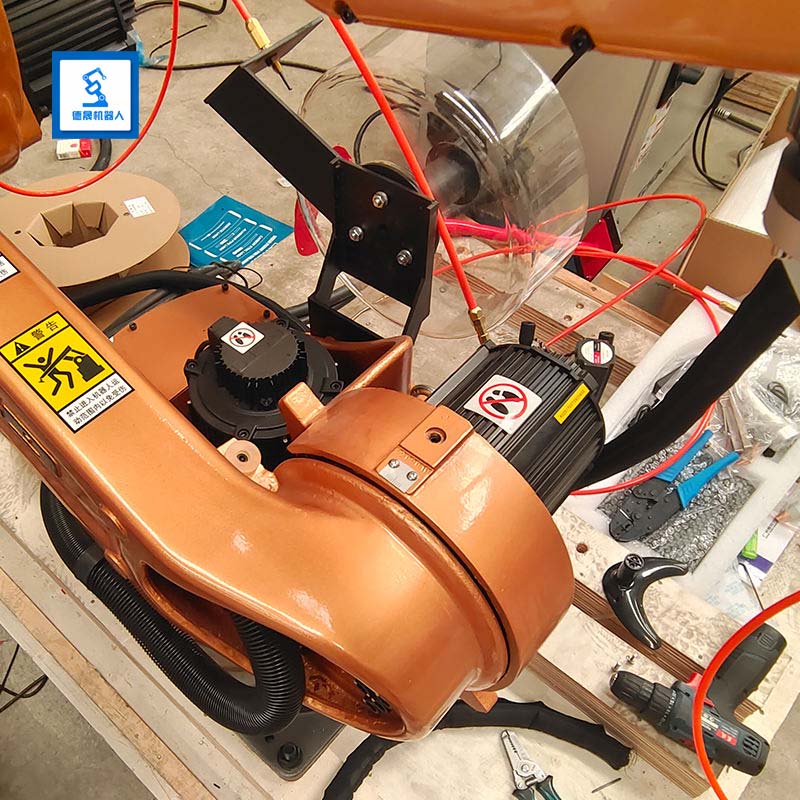

Details:

Features:

Commonality In addition to specially designed special industrial robots, general industrial robots have better commonality when performing different job tasks. For example, changing the hand end operators (claws, tools, etc.) of industrial robots can perform different job tasks.

Flexible start-up is programmable production automation's next step in development. Industrial robots can be reprogrammed according to the changing needs of their working environment, so they can play a good role in the flexible manufacturing process of small batch and variety with balanced and efficient, and are an important part of flexible manufacturing system.

Anthropomorphic industrial robots have similar walking, waist rotation, big arm, forearm, wrist, claw and other parts in the mechanical structure, there are computers in control.Additionally, intelligent industrial robots include numerous "biosensors" that are similar to those found in humans, including language capabilities, force sensors, load sensors, vision sensors, and sound sensors. Sensors improve the ability of industrial robots to adapt to the surrounding environment.

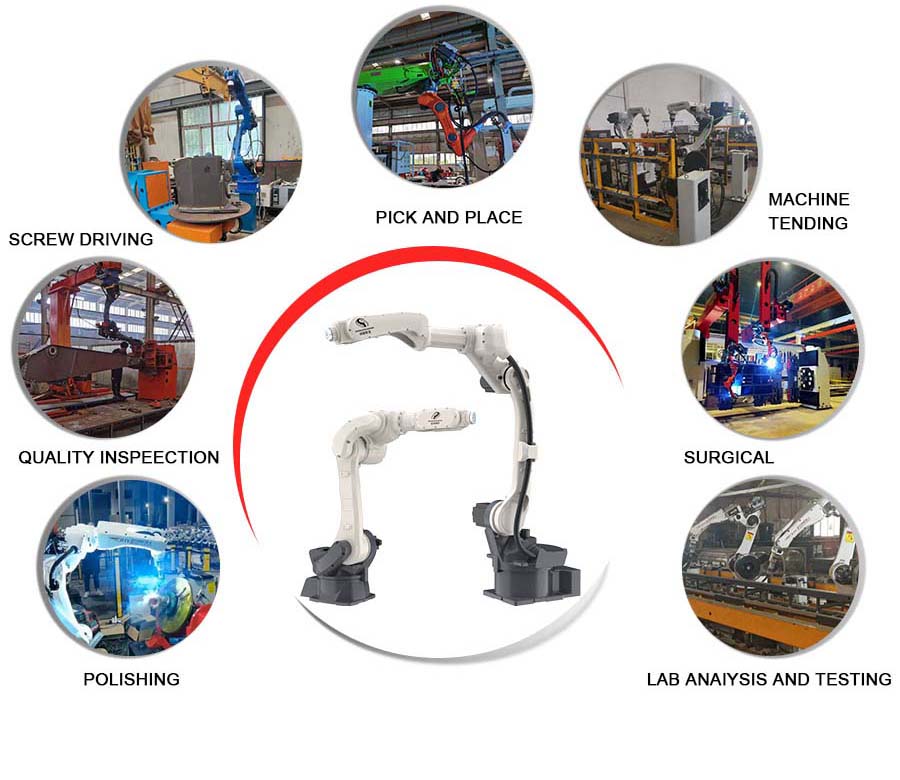

Applications:

Automobiles

Motorcycles

Construction machinery

Metallurgy

After-Sales Service:

12 months for main parts(engine,axle,body and beam,etc).

Technical Support by phone Whatsapp or email around the clock.

Lifelong Parts Supports.

Engineer available service oversea.

Packing & Shipping:

We typically use bulk cargo, flat rack, containers, and Roro ships for shipping.

We will arrange the most cost-effective transportation mode according to the quantity of products.

Before shipping, all trailers will receive a wax polishing.Every sale we close aims to have a 100% client satisfaction rate.

Delivery period: 10–20 working days following confirmation of payment receipt (depending on actual quantity).

Standard export packaging is available, as is custom packing upon request.

Professional goods shipping forwarder.

Production Line:

Certifications:

Customer Visit:

Cooperation Partner:

Exhibition:

More Products: