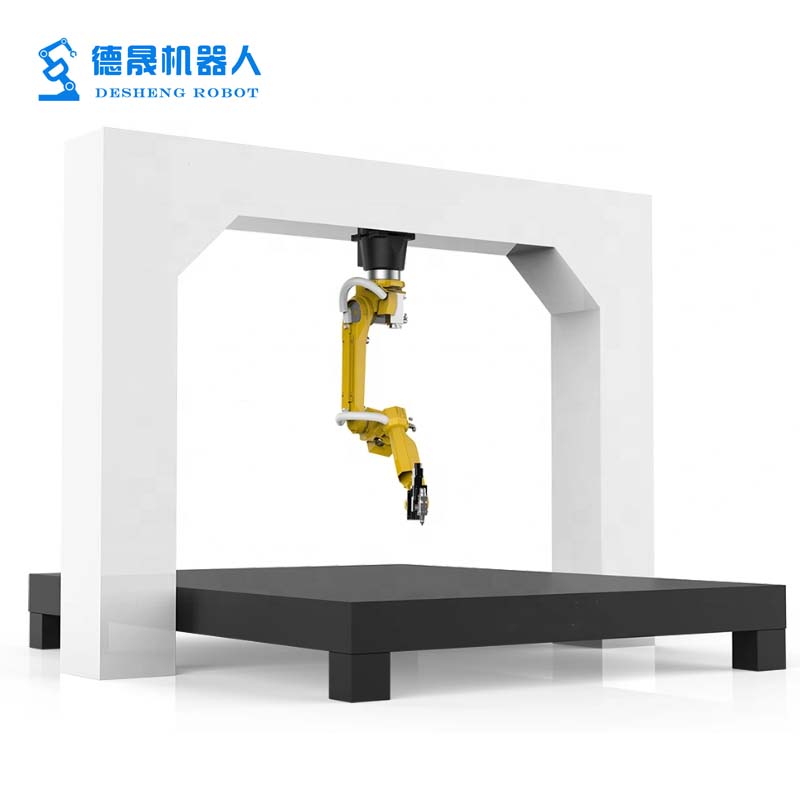

Highly Efficient Automated Welders

Welding robot arm advantages:

1,Stable welding quality, to ensure a high degree of uniformity of the product.

2,Using application robots to automate production lines is an easy way to save time and money.

3,Industrial robots also reduce waste and produce high-quality products with continuous precision.

4,Robots can also save workers from health hazards by limiting exposure to fumes and decreasing risk of arc burn.

5,24 hours can be continuously produced, the maximum increase in productivity.

Automated welding systems, along with the use of underwater welding robots, are revolutionizing the welding industry. Automatic welding has significantly increased productivity while also improving the quality of the weld. The use of an auto feed TIG welder further increases this efficiency as it allows for continuous welding without the need for stopping and starting. This automation not only saves time and money but also reduces the risk of human error and injury. With the latest advancements in technology, automatic welding, including the use of underwater welding robots and automated welding systems, is becoming the go-to solution for welding projects that require precision, speed, and reliability.

PARAMETERS:

Name | Welding robot | |||||||

Type | Vertical joint 6 degrees | |||||||

The main purpose | Laser Weld | |||||||

specification | BR10iG-14 | |||||||

Maxload weight | 10KG | |||||||

Position repeatability | 0.05mm | |||||||

Vibration | s4.9m/S | |||||||

Body weight | 149KG | |||||||

Maximum reach | 1566mm | |||||||

Conditions | 0-45RC,10-80%RH(no condensation) | |||||||

Protection class | Equivalent to lP65 | |||||||

Installation | Ground, hoisting side mounting | |||||||

Range Motion | basic | J1 | ±170° | Max | basic | J1 | 173.6°/S | |

J2 | +90°-160 | J2 | 138.8°/S | |||||

J3 | +115°-90 | J3 | 198.3°/S | |||||

arm | J4 | ±190° | arm | J4 | 288.1°/S | |||

J5 | ±140° | J5 | 400°/S | |||||

J6 | ±360° | J6 | 588.2°/S | |||||

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

FEATRUES:

Servo motor

The larqe inertia andlarge power servd motors.Ensure High-precision moving ability, to promise accuratewedingworks.

Anti-backlashgear

It doesn't matter whatangle it reaches, there will no gap between the motion. And no gap means highprecision.

Teaching programming

The control system is strong in the smart compensation function.The teaching programming makes the work simple.

APPLICATIONS:

The following fields are the primary ones in which laser welding robots are used, and when in assessment to humans, their paintings awesome and efficiency are far better than the ones of synthetic technique.

1. The manufacturing of machines

2. Motors and car elements

3. Extracting coal

4. Assets

5. Aviation

AFTER-SALES SERVICE:

1,3 hundred and sixty five days for the primary additives (engine, axle, frame, beam, and so on.).

2,Technical assistance is available 24/7 through the use of phone, whatsapp, or e-mail.

3,Supports for lifetime factors.

4,Remote places engineering offerings handy.

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER

EXHIBITION:

MORE PRODUCTS:

CONTACT US: