Intelligent Efficient Welding Robot

1. Reliable welding quality. In traditional welding, welding workers will be affected by various factors, resulting in uneven welding quality, welding robot to a greater extent to reduce the mutual interference between the cable and the fixture, easier to obtain the right attitude of the welding gun, accurate control, intelligent control system can lower just good welding materials, weld filling degree is good, stable welding quality.

2. Reliable working efficiency. Welding robot through intelligent system control, only need to set good welding parameters in the system, welding robot can work, do not need artificial interference, by human factors less, collocation of auxiliary equipment can realize automatic welding welding parts turn over, high degree of automation, realize the automation of welding process, improve the production efficiency of the enterprise.

Intelligent Efficient Welding Robot is one of the most active fields of industrial robot and can be used in a variety of applications. One of these applications is the use of robotic welding cells, where welding robots work alongside other machines to improve efficiency. Additionally, there is a market for used welding robots for sale, providing an economical option for businesses looking to invest in robotic technology. Another type of welding Robot gaining popularity is the cobot welding robot, which can work collaboratively with human workers to complete welding tasks.

Parameters:

Welding robot main technical parameters | ||||

Model | 10006A-144 | 10006A-180 | ||

Name | welding robot | welding robot | ||

Type | Vertical 6 axis | Vertical 6 axis | ||

Main purpose | welding.transportation | welding.transportation | ||

Wrist load | 6KG | 6KG | ||

Repeated positioning accuracy | ±0.08mm | ±0.08mm | ||

Power capacity | 1.5KVA | 3.7KVA | ||

Motion range of P | as picture shows | as picture shows | ||

Self weight | 170KG | 210KG | ||

Motion range | basic axis | J1 | ±170° | ±170° |

J2 | +155° -90° | +155° -85° | ||

J3 | +68° -82° | +80° -90° | ||

arm axis | J4 | ±150° | ±170° | |

J5 | ±112° | +125° -90° | ||

J6 | ±330° | ±220 | ||

Max speed | basic axis | J1 | 119°/s | 136°/s |

J2 | 136°/s | 135°/s | ||

J3 | 137°/s | 125°/s | ||

arm axis | J4 | 160°/s | 150°/s | |

J5 | 156°/s | 150°/s | ||

J6 | 346°/s | 333°/s | ||

Installation | Ground | Ground | ||

Environmental condition | 0-45°,20-80%RH,without dew | 0-45°,20-80%RH,without dew | ||

Protection level | Equivalent to IP67 | Equivalent to IP67 | ||

Details:

Features:

1. Increase overall loading capacity by using welding platforms, heavy-duty guide rails, and humanized structure designs that make machine-to-machine interchange more reasonable and practical.

2. An independently created CNC control system for pipes. Standard G code, three-dimensional simulation operations, node expansion, over length pipe splitting, pipe optimization, etc. may all be generated from engineer design drawings created in AutoCAD. EGES DXF SAT and STL software compatibility, etc. a lifetime of upgrade and modification services in accordance with the technical specifications of the clients.

3. The Advantech industrial computer can be directly programmed for a machine. Choose input cutting parameters from a menu by using the menu type, such as external diameter, thickness, beveled edges angle, deviation, compensation data, etc. to use a professional pipe cutting application tool to link everything seamlessly.

Applications:

The following fields are the main ones where laser welding robots are used, and when compared to humans, their work quality and efficiency are far higher than those of artificial means.

1, the production of machines

2. Vehicles and automobile parts

3. extracting coal

4. Resources

5. Aviation

After-Sales Service:

1,12 months for the major components (engine, axle, body, beam, etc.).

2, Technical help is available 24/7 by phone, Whatsapp, or email.

3, Supports for Lifetime Parts.

4, Overseas engineering services accessible.

Package and shipping:

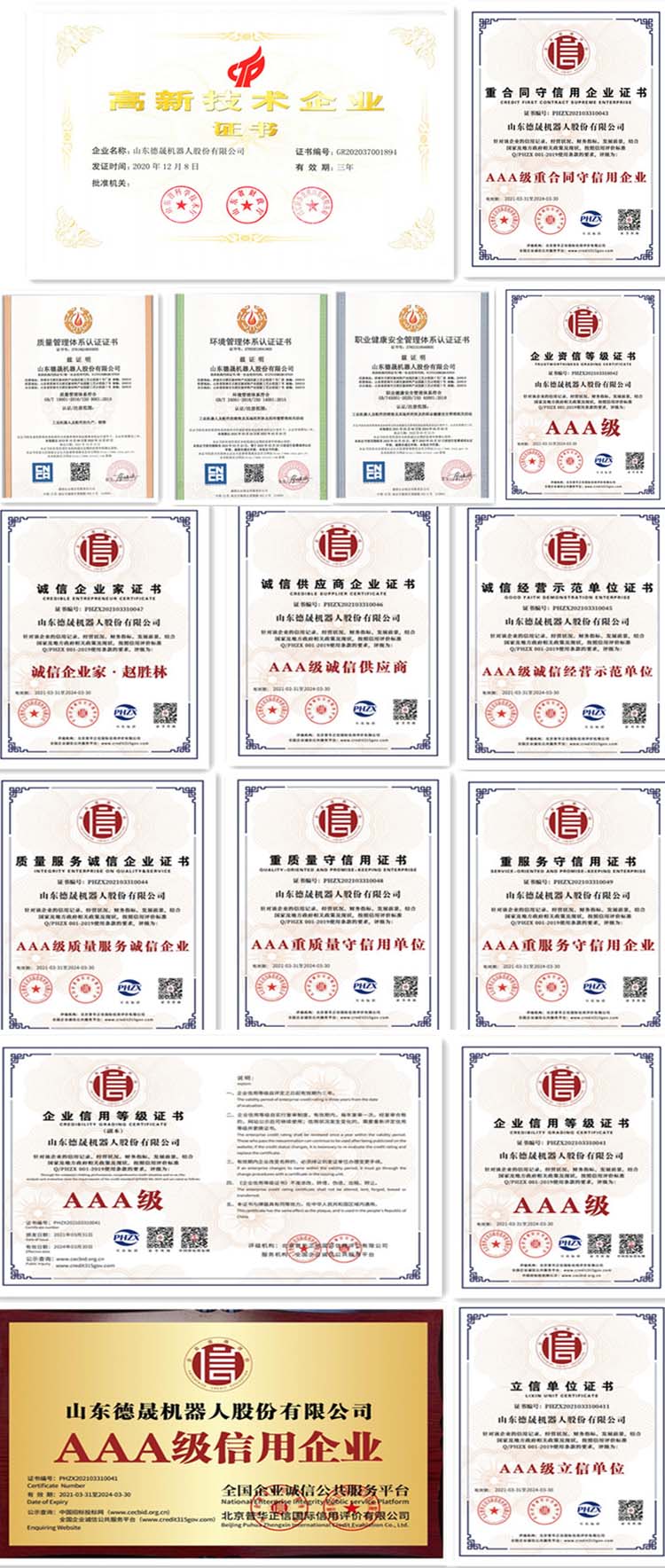

Certifications:

Cooperation Partner:

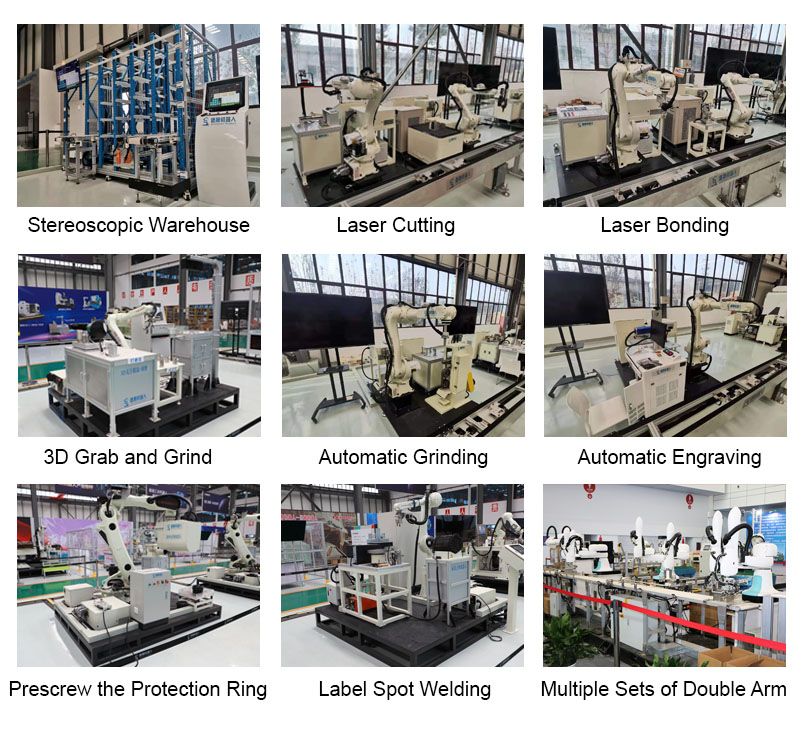

More Products: