Robotic Production Technology

Advantages of Robotic Production Technology:

1,Increased efficiency: Robotic production technology can greatly improve efficiency in manufacturing processes. Robots can work continuously without breaks or fatigue, resulting in higher productivity and faster turnaround times. They can also perform repetitive tasks with precision and accuracy, minimizing errors and waste.

2,Improved quality control: Robots are capable of performing intricate and delicate tasks with exact precision, resulting in higher quality products. They can consistently measure and inspect parts, ensuring that they meet the required specifications. This reduces the likelihood of defects and improves overall product quality.

3,Enhanced safety: By automating certain tasks, robotic production technology can help reduce the risk of injuries to human workers. Robots can handle hazardous materials or perform dangerous tasks in environments that may not be safe for humans. This improves workplace safety and reduces the potential for accidents or injuries.

Robotic Production Technology:

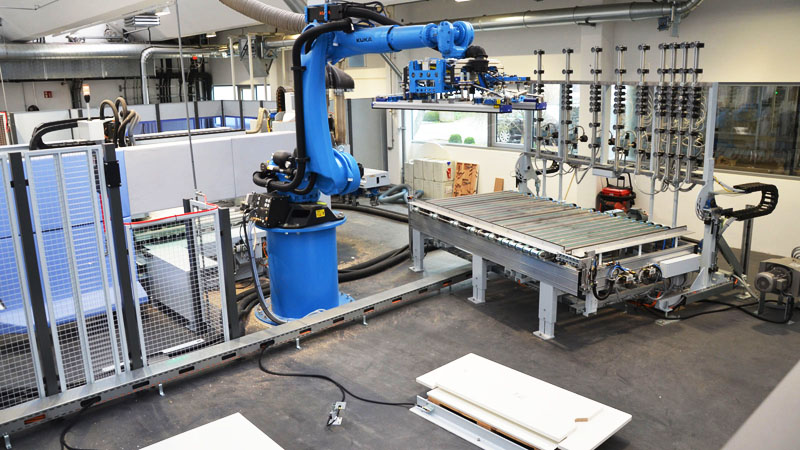

The Kuka 7 Axis Robot offers advanced capabilities and flexibility for various industrial applications. With its advanced technology and precision, this robot comes at a competitive price, making it an attractive option for businesses. Another innovative technology is the Automatic Wall Painting Robot, which provides efficient and accurate painting results. For those looking for cost-effective options, used industrial robots are available in the market, offering reliable performance at a lower price. Additionally, the Bag Palletizing Robot offers speed and precision in stacking bags, streamlining the palletizing process. These robots are revolutionizing the industry by enhancing productivity and efficiency.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

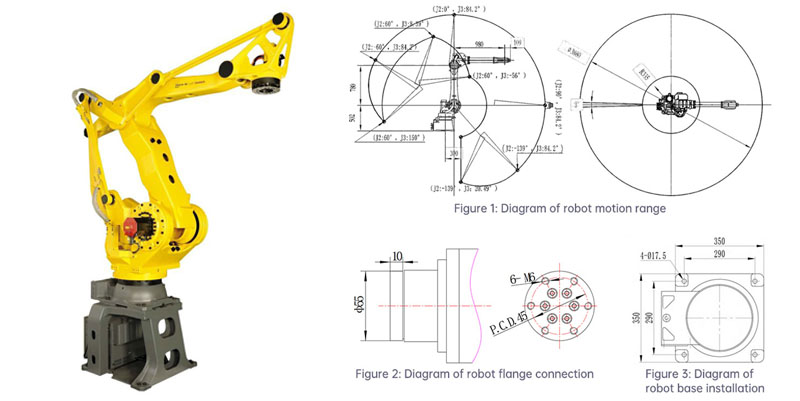

DIMENSIONAL DRAWINGS:

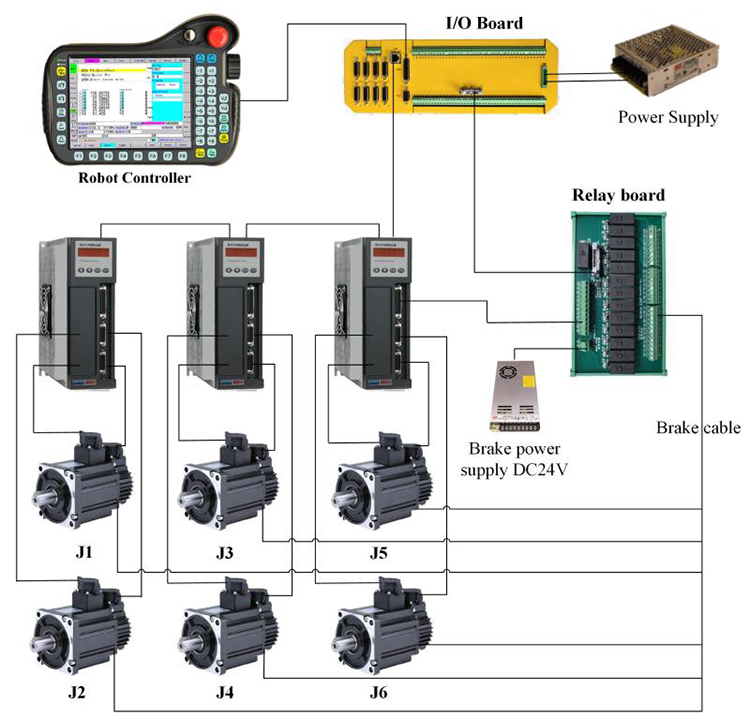

ROBOT CONTROLSYSTEM:

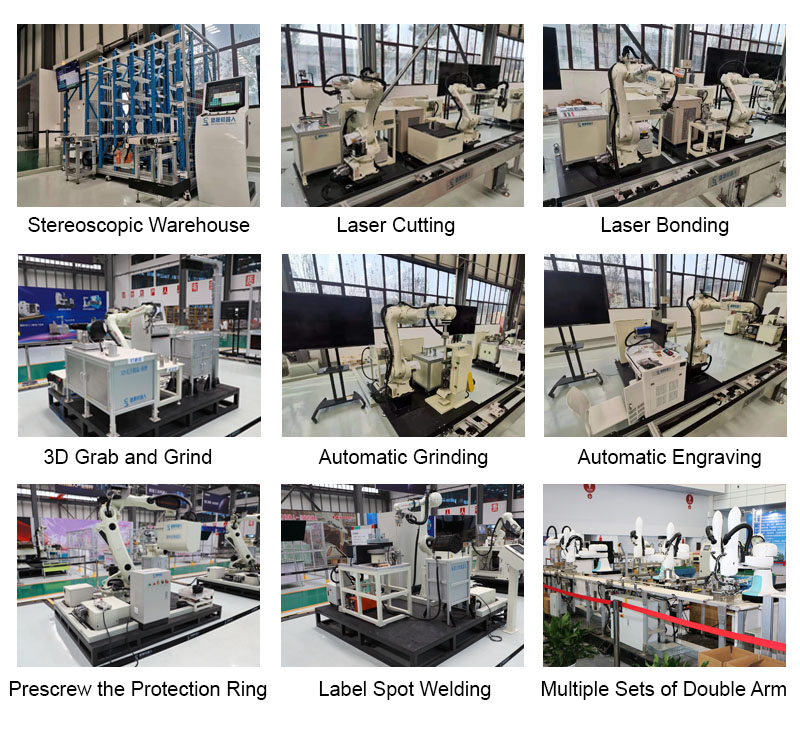

APPLICATIONS:

1,Assembly line automation: The Kuka 7 Axis Robot is commonly used in assembly line applications, where it can handle complex assembly tasks with precision and efficiency. It can perform tasks such as picking and placing components, tightening bolts, and welding. This helps streamline the assembly process and reduce human error, resulting in higher productivity and improved product quality.

2,Material handling: The Kuka 7 Axis Robot is also widely utilized for material handling tasks. It can lift heavy objects, move them to different locations, and place them with accuracy. This is particularly useful in industries such as logistics and warehousing, where there is a need to move large and heavy items quickly and safely.

3,CNC machining: Another application of the Kuka 7 Axis Robot is in CNC machining. It can be programmed to operate CNC machines, allowing for automated machining processes. This eliminates the need for manual operation and reduces the risk of errors. The robot can control the movement of the machine tool with precision, resulting in consistent and accurate machining results.

FEATURES:

1,High precision: The Kuka 7 Axis Robot is known for its exceptional precision in performing tasks. With its seven axes of movement, it can achieve complex motions and accurately position objects with high repeatability. This precision is crucial in industries where intricate tasks or tight tolerances are required.

2,Versatility: The Kuka 7 Axis Robot is highly versatile and can be used in various applications across different industries. It can handle a wide range of tasks, including assembly, material handling, welding, painting, and machining. Its flexibility and adaptability make it a valuable asset for businesses with diverse manufacturing needs.

3,Advanced technology: The Kuka 7 Axis Robot features advanced technology that enhances its performance and capabilities. It is equipped with sensors and control systems that enable it to detect and adjust to changes in its environment. This allows for improved safety, increased productivity, and seamless integration with other systems in the manufacturing process.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: