Universal Robots Ur20 Series

Advantages of Universal Robots Ur20 Series:

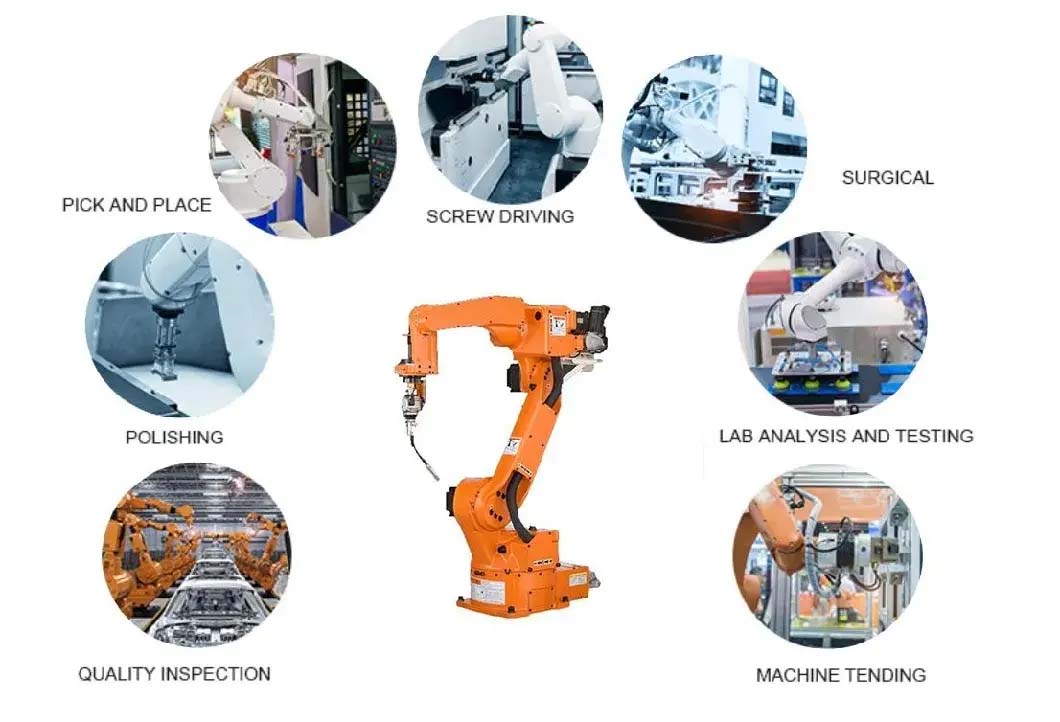

1,Versatility: The UR20 Series is designed to handle a wide range of tasks and applications, including machine tending, assembly, pick and place, and packaging. Its flexible and easy-to-use programming interface allows for quick adaptation to different tasks.

2,Safety: Universal Robots has integrated safety features in the UR20 Series, such as adjustable speed and force limits, collision detection, and a responsive emergency stop function. This ensures safe interaction between the robot and human operators.

3,Cost-effectiveness: The UR20 Series is a cost-effective solution for automation needs. Its compact size and lightweight design simplify installation and reduce the need for additional infrastructure. The collaborative nature of the UR20 Series also eliminates the need for safety guarding, making it a cost-saving option.

Universal Robots Ur20 Series:

The Universal Robots UR20 Series is revolutionizing industrial plant automation with its new automation technology. With its advanced features, it has become a game-changer in the field of industrial automation and process control.

The UR20 Series offers a wide range of applications, making it suitable for various industries. Its user-friendly programming interface allows for easy customization and adaptation to different tasks, making automation more accessible to companies of all sizes.

One of the key advantages of the UR20 Series is its collaborative nature. This means that it can work alongside human operators without the need for safety guarding, increasing efficiency and reducing costs.

Furthermore, the UR20 Series is designed with safety in mind. It has integrated safety features such as adjustable speed and force limits, collision detection, and an emergency stop function, ensuring a safe working environment.

With its cost-effectiveness, versatility, and emphasis on safety, the Universal Robots UR20 Series is shaping the future of industrial plant automation and setting new standards in the industry.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | sICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEw | |||

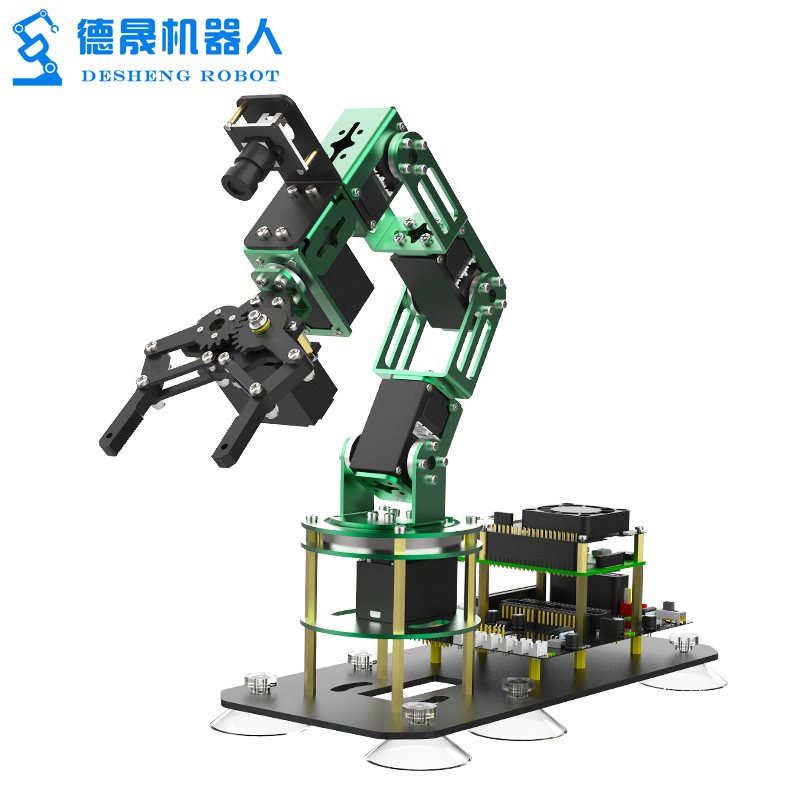

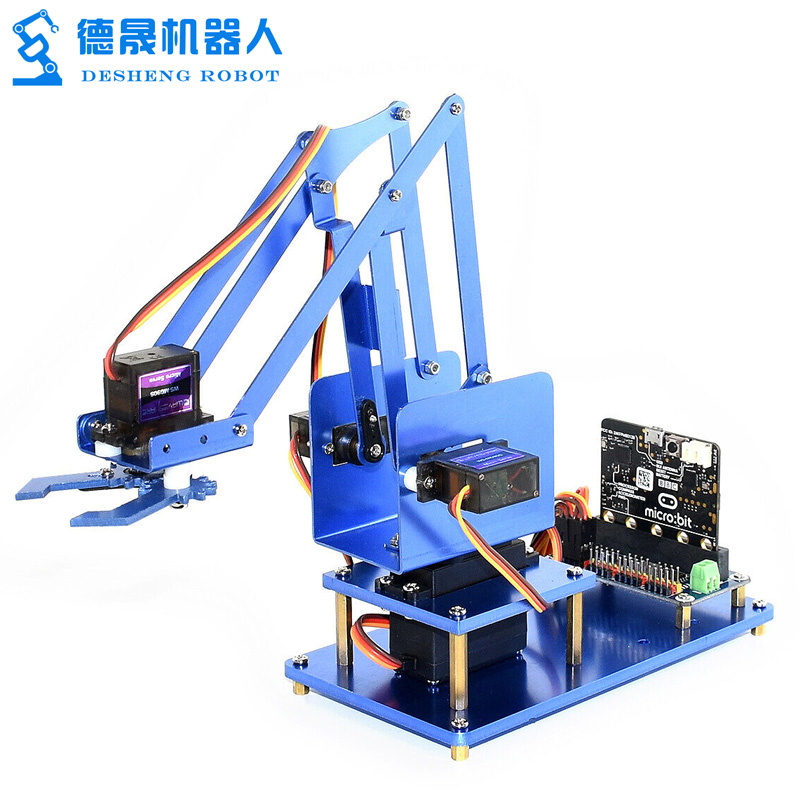

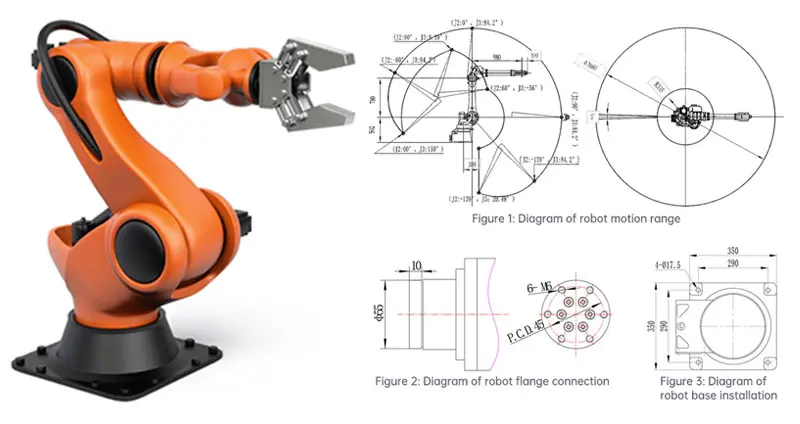

DIMENSIONAL DRAWINGS:

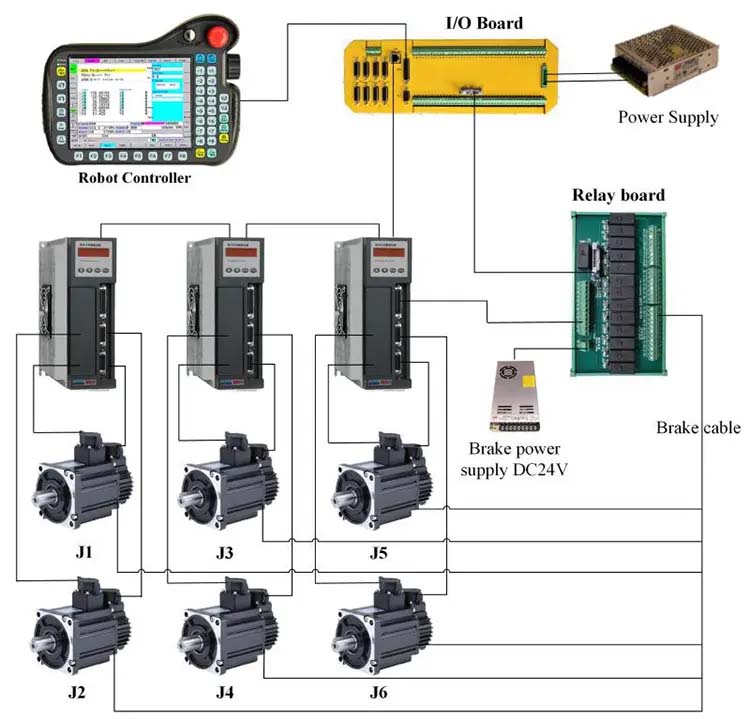

ROBOT CONTROLSYSTEM:

APPLICATIONS:

FEATURES:

1,Collaborative Capability: The UR20 Series is designed to work safely alongside human operators, without the need for safety guarding. This collaborative capability allows for efficient and flexible human-robot interaction, increasing productivity.

2,Easy Programming: The UR20 Series offers a user-friendly programming interface that simplifies task customization and adaptation. It allows users to quickly and easily program the robot to perform various tasks, making it accessible even to those without prior programming experience.

3,Advanced Safety Features: Universal Robots has integrated advanced safety features into the UR20 Series, including adjustable speed and force limits, collision detection, and an emergency stop function. These safety measures ensure the well-being of human operators working in close proximity to the robot.

OUR SERVICE:

CERTIFICATIONS:

COOPERRATION PARTNER:

CONTACT US: