Mobile Robot Solutions for Industrial Applications

Advantages of Mobile Robot Solutions for Industrial Applications:

1,Flexibility and adaptability: Mobile robot solutions offer high flexibility and adaptability, allowing them to navigate and operate in various environments and settings. They can easily be deployed and reconfigured to meet changing operational needs, making them versatile for different industries and applications.

2,Improved productivity and efficiency: Mobile robots are designed to optimize productivity and efficiency by automating various tasks and workflows. Their autonomous navigation capabilities enable them to work in unstructured environments and collaborate with human workers, enhancing overall operational efficiency.

3,Enhanced safety and risk reduction: Mobile robot solutions prioritize safety and risk reduction. Equipped with advanced sensors and collision avoidance technology, these robots can detect and navigate around obstacles, minimizing the potential for accidents or damage. They can be programmed to operate in a safe manner, ensuring the well-being of both the workforce and the equipment.

Mobile Robot Solutions for Industrial Applications:

Mobile robot solutions have become increasingly popular in industrial applications, revolutionizing the way automation is used in various industries. Industrial automation engineers play a critical role in implementing and optimizing these solutions, ensuring seamless integration into existing production lines. These mobile robots are equipped with advanced technology and sensors, allowing them to navigate and operate autonomously in dynamic environments. They are often used for automated material handling tasks, efficiently transporting goods and streamlining logistics operations. In addition, mobile robots are widely utilized in palletizing applications, as they can accurately and efficiently stack and arrange products. With the collaboration of industrial automation engineers and robotic palletizer manufacturers, mobile robot solutions continue to advance, offering improved efficiency, increased productivity, and cost savings in industrial automation processes.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

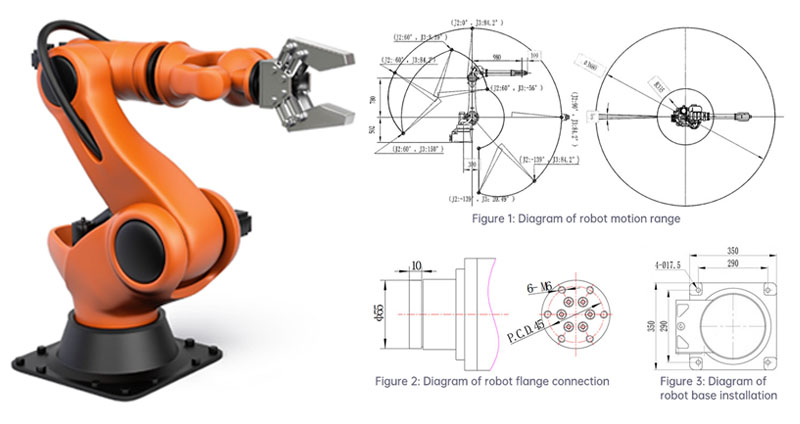

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

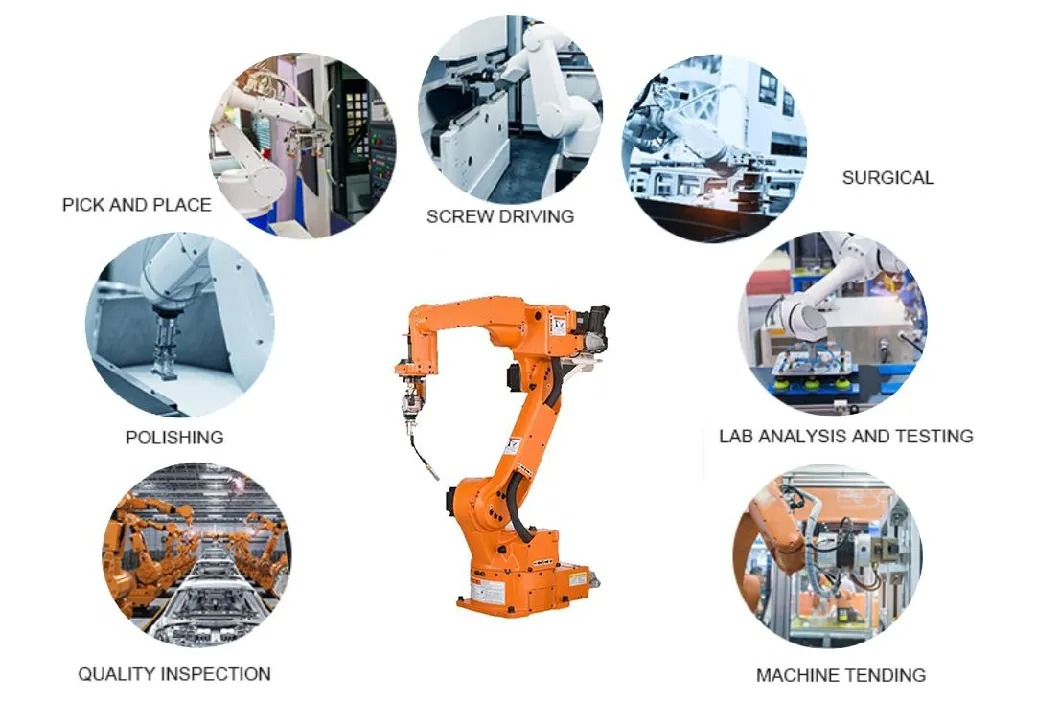

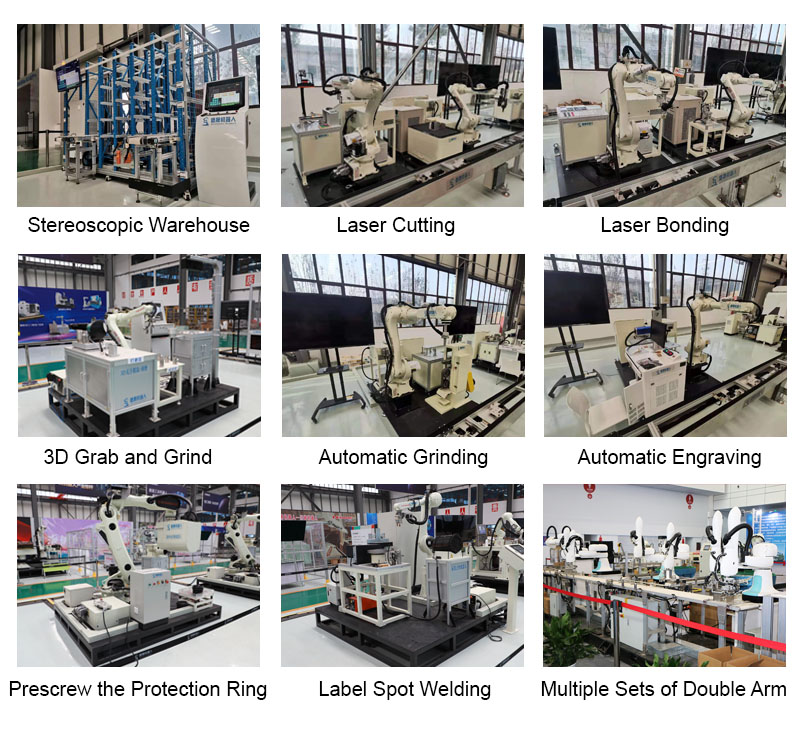

APPLICATIONS:

FEATURES:

1,Flexibility and versatility: Mobile robot solutions offer remarkable flexibility and versatility, allowing them to navigate and operate effectively in different environments and tasks. They can be easily reconfigured to adapt to changing requirements, making them suitable for a range of industrial applications.

2,Autonomous navigation: Mobile robots are equipped with advanced sensors, mapping, and navigation systems that enable them to move autonomously. They can intelligently navigate through complex environments, avoiding obstacles and adjusting their path as needed, leading to efficient and safe operations.

3,Collaborative capabilities: Mobile robot solutions have the ability to collaborate and interact with human workers. They can be programmed to work alongside humans, assisting in tasks, and improving overall productivity. Their collaborative nature enables effective human-robot cooperation, unlocking new possibilities for efficient and harmonious industrial workflows.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: