Leading Industrial Robot Manufacturers

Advantages of Leading Industrial Robot Manufacturers:

1,Increased Productivity: Industrial robots can work at a high speed with consistent precision, leading to increased productivity levels for industries. They can perform repetitive tasks without fatigue, allowing for continuous operations and higher output.

2,Improved Efficiency: With their advanced technology and programming, industrial robots can streamline processes and minimize errors. Their accuracy and reliability contribute to improved efficiency by reducing waste, rework, and downtime. This helps industries optimize their operations and achieve cost savings.

3,Enhanced Safety: Industrial robots can handle hazardous and dangerous tasks, keeping human workers safe by minimizing their exposure to risks. They can operate in environments with high temperatures, toxins, or heavy loads, ensuring a safer working environment for employees. This also reduces the chances of workplace accidents and injuries.

Leading Industrial robot Manufacturers:

Emerson Industrial Automation, a leading Industrial Robot manufacturer, specializes in providing automation solutions for the aerospace industry. With their plant automation technology, they offer tailored aerospace industry automation solutions that enhance productivity, accuracy, and safety. By integrating advanced robotics systems with existing operations, Emerson Industrial Automation optimizes production output while ensuring high precision and quality control. Their solutions also minimize human intervention in hazardous processes, prioritizing worker safety and the overall integrity of aerospace products. For the aerospace industry, Emerson Industrial Automation offers reliable and innovative automation solutions that drive efficiency and elevate operational standards.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

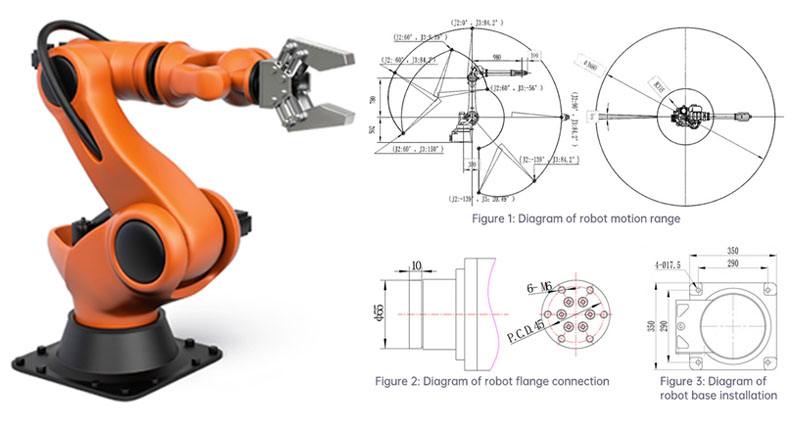

DIMENSIONAL DRAWINGS:

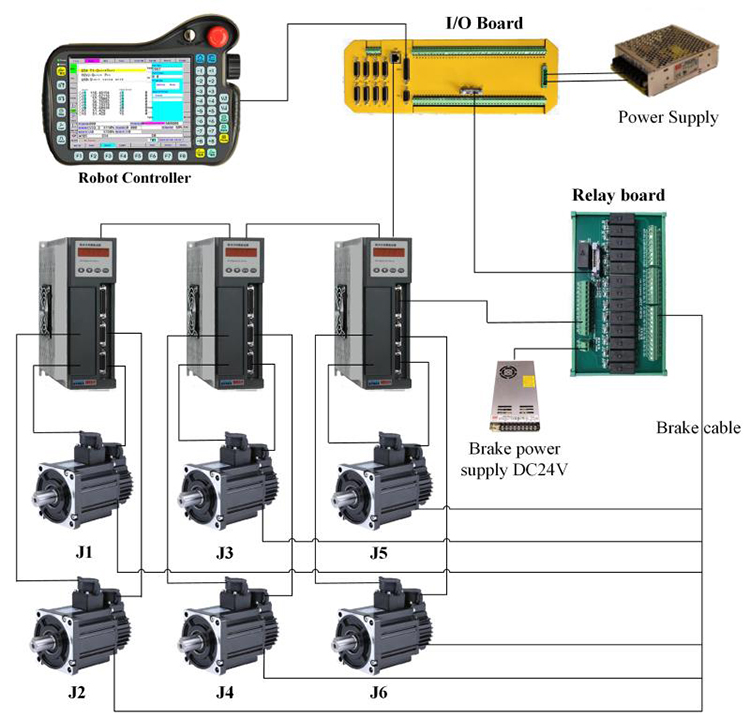

ROBOT CONTROLSYSTEM:

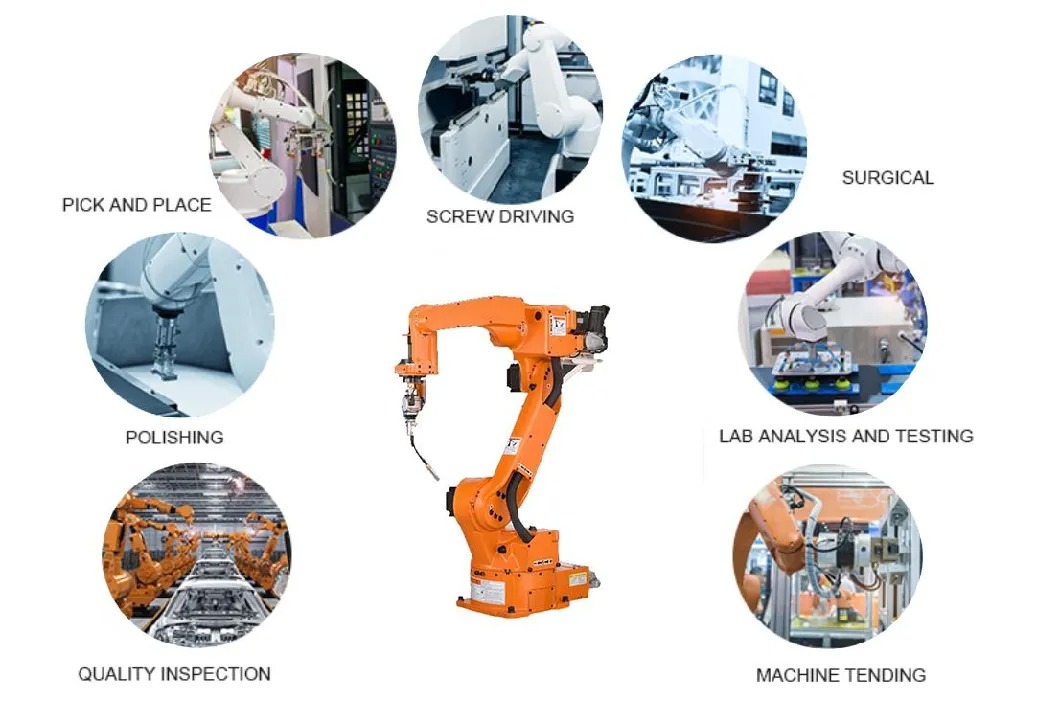

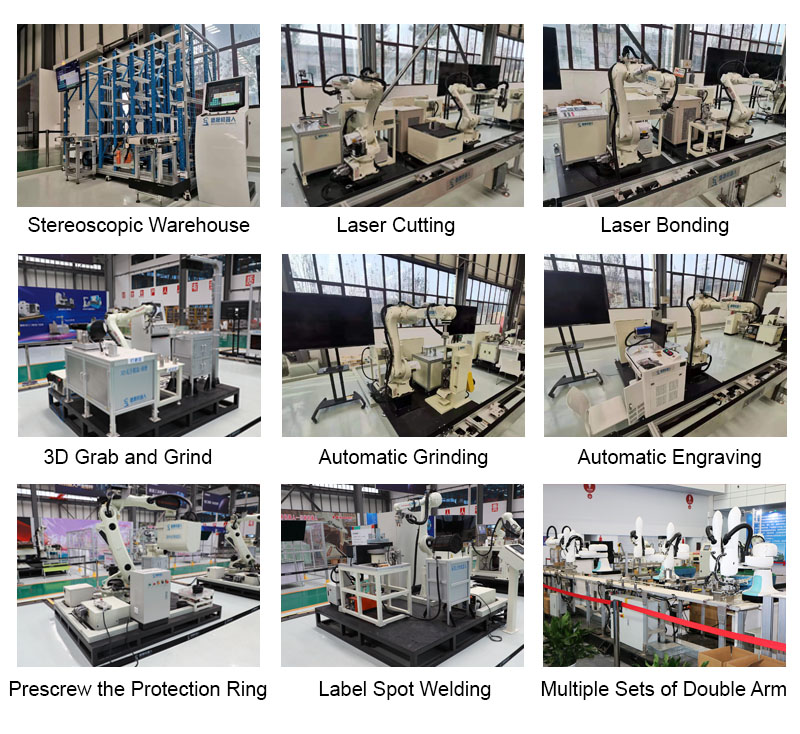

APPLICATIONS:

FEATURES:

1,Precision and Accuracy: Industrial robots are designed to perform tasks with high precision and accuracy. They can repeat the same motion consistently, resulting in reliable and precise outcomes. This ensures a consistent level of quality in manufacturing processes.

2,Flexibility and Versatility: Industrial robots are engineered to be flexible and adaptable. They can be programmed to perform different tasks and handle various materials. Their versatility allows for seamless integration into different production lines and enables manufacturers to quickly switch between different products or production processes.

3,Automation and Efficiency: Industrial robots help automate repetitive and labor-intensive tasks, leading to increased efficiency and productivity. By taking over monotonous tasks, robots free up human workers to focus on more critical and complex activities. This not only improves overall efficiency but also reduces the risk of human error and increases output.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: