Integration ATI Robotics Solutions

Advantages of Integration ATI Robotics Solutions:

Enhanced Performance: ATI Robotics Solutions are designed to seamlessly integrate with existing robotic systems, enhancing their performance and capabilities. This integration enables robots to handle complex tasks more efficiently and accurately, resulting in improved productivity and cost-effectiveness.

Versatility and Flexibility: ATI Robotics Solutions provide a wide range of products and accessories that can be integrated into various robotic applications. Their modular design allows for easy customization and adaptability, enabling robots to handle a diverse range of tasks and applications.

Increased Efficiency and Reliability: By integrating ATI Robotics Solutions, robotic systems can benefit from enhanced functionality, such as advanced force/torque sensing, compliance, and precision gripping. These features enable robots to handle delicate objects, perform intricate assembly tasks, and achieve higher accuracy and repeatability, leading to increased efficiency and reliability in production processes.

Integration ATI Robotics Solutions:

Integration of ATI Robotics Solutions, B And R Automation, Illukkumbura Industrial Automation, and Industrial Automation Using IoT has revolutionized the manufacturing industry. This collaboration between leading automation companies has resulted in enhanced efficiency, productivity, and cost savings for businesses. By integrating cutting-edge technologies and intelligent systems, these solutions have streamlined production processes, reduced errors, and improved overall quality. Furthermore, the utilization of IoT in industrial automation has allowed for real-time monitoring, predictive maintenance, and remote control, providing companies with unprecedented control and visibility over their operations. With these advanced automation solutions, manufacturers can elevate their performance and pave the way for a smarter and more connected future.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | sICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEw | |||

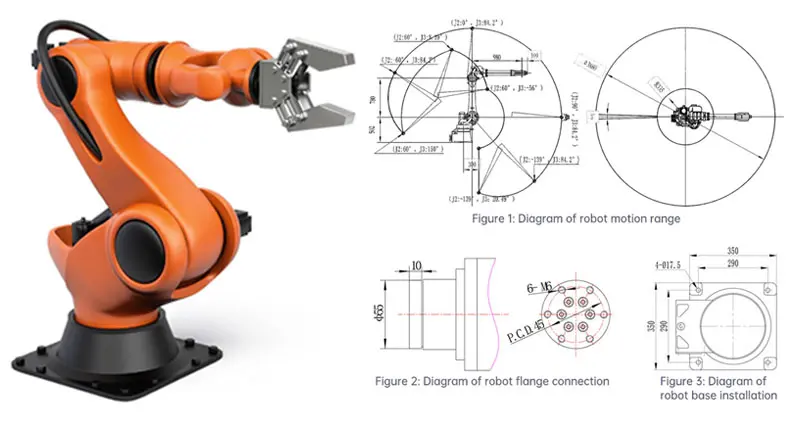

DIMENSIONAL DRAWINGS:

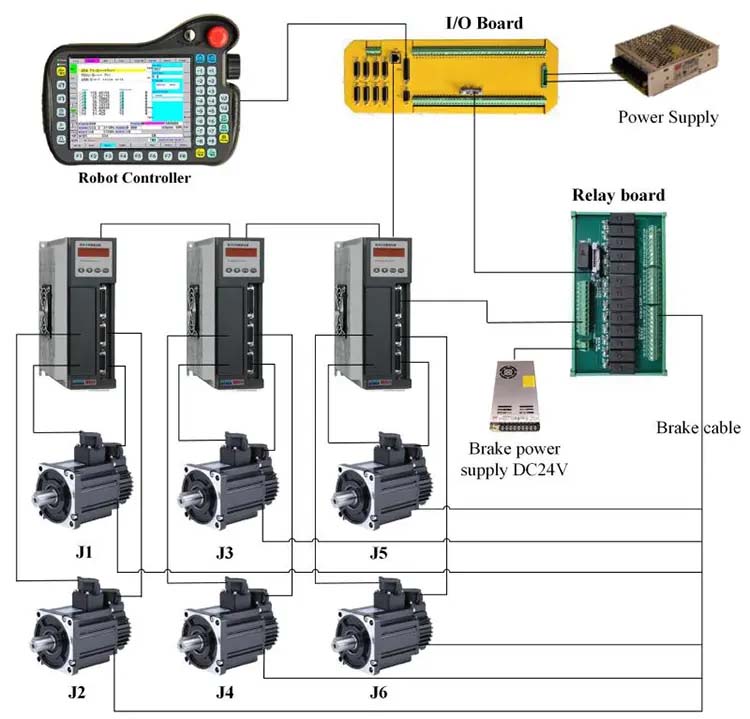

ROBOT CONTROLSYSTEM:

FEATURES:

1,Advanced Robotics Technology: ATI Robotics Solutions incorporate cutting-edge robotics technology to automate various manufacturing processes. With the use of precise and efficient robotic arms, companies can achieve higher levels of accuracy and speed, leading to improved productivity and output.

2,Seamless Integration: These solutions seamlessly integrate with existing manufacturing systems, allowing for easy adoption and implementation. By integrating ATI Robotics Solutions, companies can optimize their operations without disrupting their existing processes, minimizing downtime and maximizing efficiency.

3,Customizability and Flexibility: ATI Robotics Solutions offer a high degree of customization and flexibility to cater to the specific needs of different industries. Whether it's assembly, material handling, or quality control, these solutions can be tailored to meet the unique requirements of each manufacturing environment, ensuring optimal performance and ROI.

OUR SERVICE:

CERTIFICATIONS:

COOPERRATION PARTNER:

CONTACT US: