Flexible Handling Robot Solutions

Advantages of Flexible Handling Robot Solutions:

1,Versatility: This robot is highly versatile and can be programmed to handle a wide range of objects and materials, making it suitable for various applications. Its flexible grippers and adaptive motion control enable it to handle different shapes, sizes, and weights with ease.

2,Efficiency: The Flexible Handling Robot is designed for maximum efficiency. Its fast and precise movements result in reduced cycle times and increased productivity. Additionally, it can seamlessly integrate into existing production lines, optimizing workflow and reducing downtime.

3,Safety: Safety features are incorporated into the design of the Flexible Handling Robot to ensure a secure work environment. Collaborative capabilities allow it to work side by side with human operators safely. Protective sensors and software enable the robot to detect obstacles and avoid collisions, minimizing the risk of accidents.

Flexible Handling Robot Solutions:

Flexible Handling Robot Solutions, in collaboration with Industrial Automation Systems, Automated Optical Inspection Systems, and Components for Industrial Automation, revolutionize the manufacturing industry. These cutting-edge technologies offer increased efficiency, accuracy, and adaptability.

The combination of Flexible Handling Robot Solutions with Industrial Automation Systems provides a versatile and agile automation solution for various industries. This integration optimizes production processes, reduces cycle times, and increases productivity.

Automated Optical Inspection Systems enhance quality control by ensuring precise and accurate inspection of products during production. This advanced technology detects defects and inconsistencies, improving product quality and reducing waste.

Components for Industrial Automation offer seamless integration of different systems and machinery. From control panels to sensors and actuators, these components enable smooth communication and coordination between various automated processes, resulting in optimized workflow and enhanced operational efficiency.

In conclusion, the collaboration between Flexible Handling Robot Solutions, Industrial Automation Systems, Automated Optical Inspection Systems, and Components for Industrial Automation represents a powerful combination that transforms the manufacturing industry. These technologies work together to provide increased efficiency, accuracy, and adaptability, driving innovation and success in the manufacturing sector.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

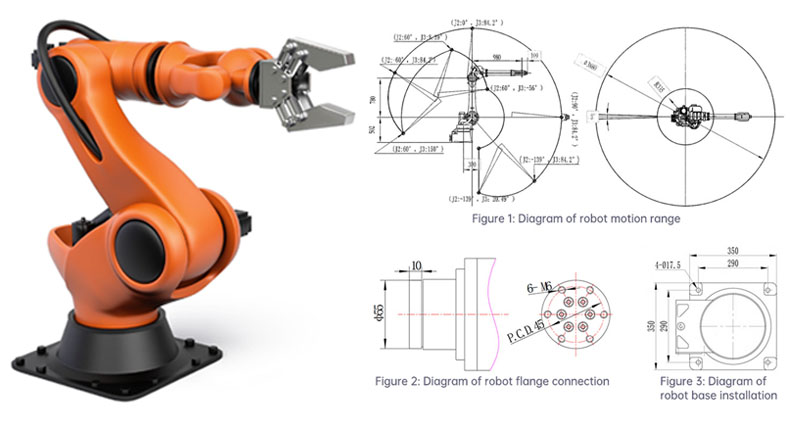

DIMENSIONAL DRAWINGS:

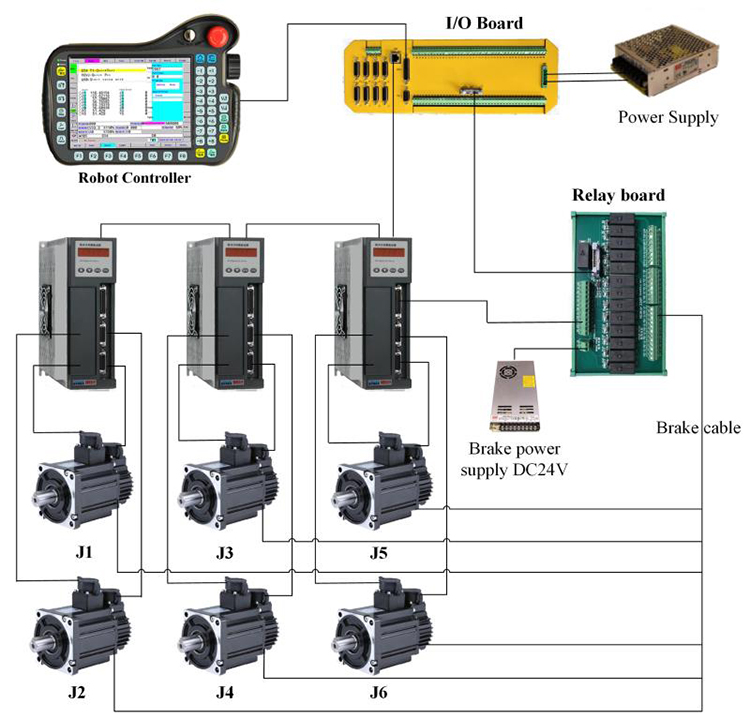

ROBOT CONTROLSYSTEM:

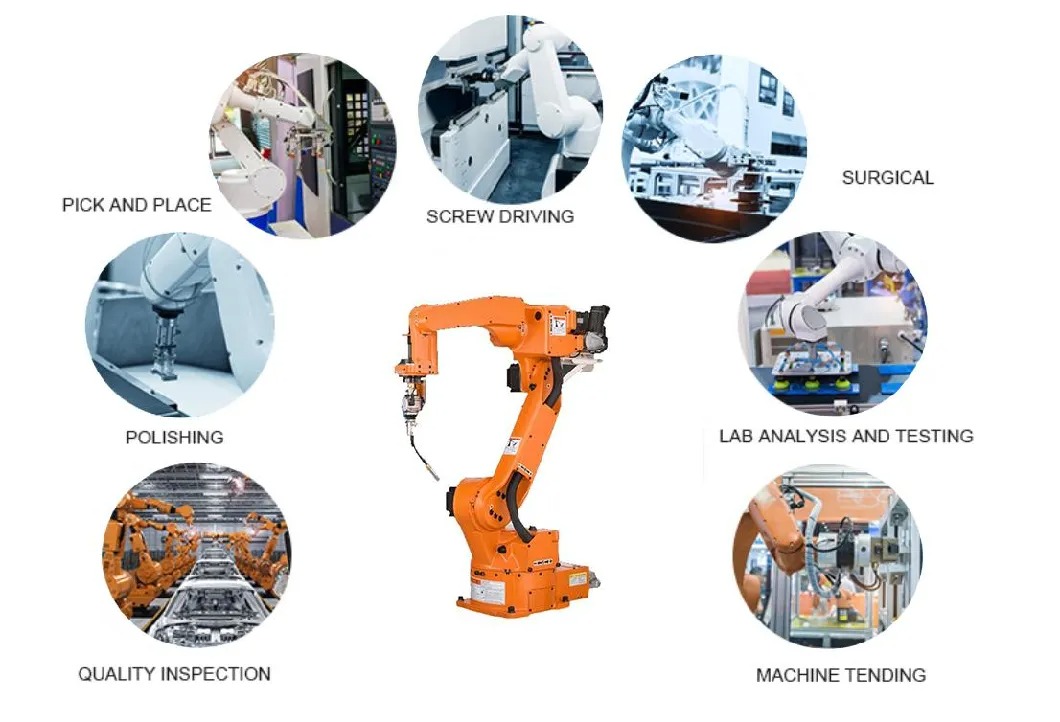

APPLICATIONS:

FEATURES:

1,Versatile Gripping Capability: These solutions offer a wide range of grippers that can handle various objects and materials. Whether it's delicate electronic components or heavy industrial parts, the flexible grippers can adapt to different shapes, sizes, and weights, ensuring a high level of versatility in handling operations.

2,Adaptive Motion Control: The Flexible Handling Robot Solutions incorporate advanced motion control technology, allowing for precise and flexible movements. With the ability to adjust speed, acceleration, and path planning, the robots can navigate complex environments and perform intricate tasks with accuracy and efficiency.

3,Easy Integration and Programming: These solutions are designed for seamless integration into existing manufacturing systems. They can be programmed and configured quickly, enabling a fast setup and minimizing downtime. In addition, they offer intuitive programming interfaces that simplify the task of defining and modifying tasks, making it easier for operators to adapt the robot's functionality as needed.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

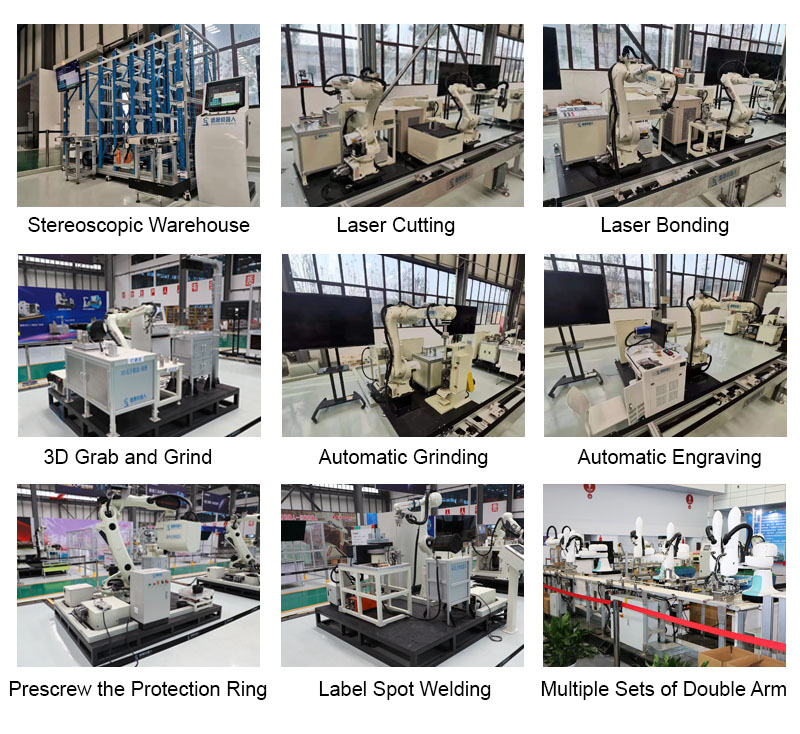

EXHIBITION:

MORE PRODUCTS:

CONTACT US: