Autonomous Robots Industry 4.0

Advantages of Autonomous Robots Industry 4.0:

1,Increased productivity: Autonomous robots can perform repetitive tasks with precision and consistency, leading to higher productivity levels. They can work continuously without the need for breaks, resulting in improved efficiency and output.

2,Enhanced safety: Autonomous robots can be programmed to work in dangerous or hazardous environments, reducing the risk to human workers. They can handle heavy machinery, operate in extreme temperatures or toxic environments, minimizing the potential for accidents or injuries.

3,Cost savings: Autonomous robots can lower operational costs by reducing manual labor requirements. They can perform tasks faster and more accurately, leading to decreased labor expenses. Additionally, they can optimize energy usage and reduce downtime, resulting in overall cost savings for businesses.

Autonomous Robots Industry 4.0:

Autonomous Robots Industry 4.0, combined with advanced Industrial Control Equipment, offers a groundbreaking automation solution. Companies like Rockwell Technologies and Panasonic Industrial Automation are at the forefront of developing and implementing this technology.

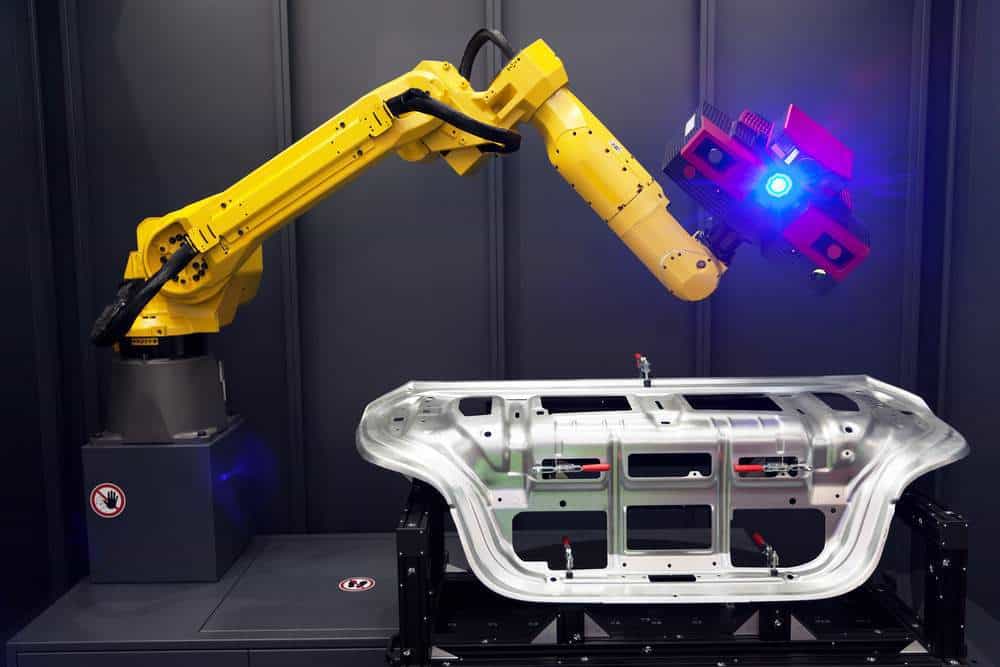

Autonomous robots, equipped with cutting-edge sensors and AI algorithms, are revolutionizing the manufacturing industry. They can work tirelessly, ensuring increased productivity and efficiency. Industrial Control Equipment further enhances their capabilities, allowing seamless integration into existing manufacturing processes.

Rockwell Technologies, a leader in automation solutions, provides state-of-the-art control systems that enable real-time monitoring and optimization. Panasonic Industrial Automation offers a wide range of automated solutions, including robotic arms, vision systems, and control centers.

Together, these technologies streamline operations, improve safety, and reduce costs. With the growth of Industry 4.0, autonomous robots and advanced control equipment will continue to drive innovation, transforming the manufacturing landscape.

PARAMETERS:

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s per cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons, cases,bags, pouch bags | Containers,bottles,cans,buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | sICK | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEw | |||

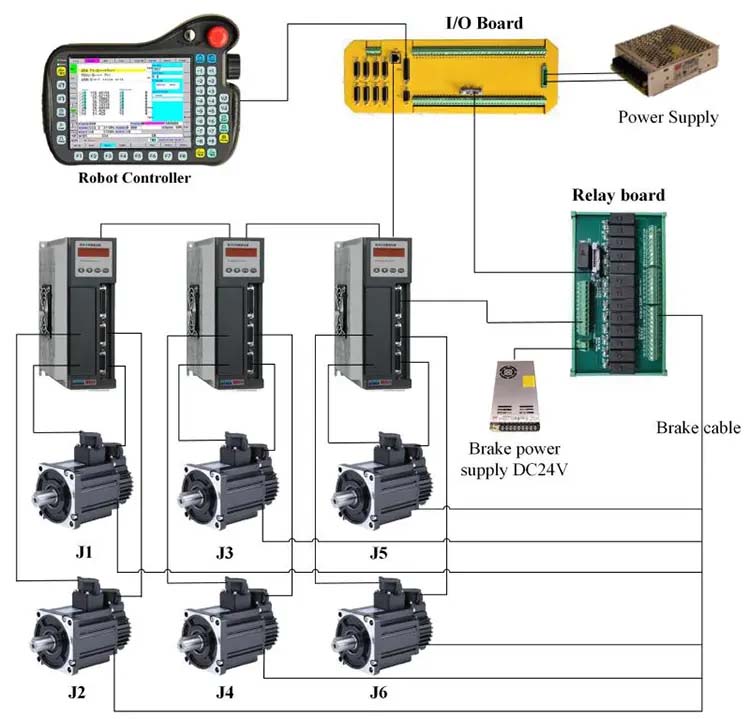

ROBOT CONTROLSYSTEM:

OUR SERVICE:

COOPERRATION PARTNER:

CONTACT US:

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s per cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons, cases,bags, pouch bags | Containers,bottles,cans,buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | sICK | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEw | |||