Automation And Robotics In Construction

Advantages of Automation And Robotics In Construction:

Automation and robotics in construction offer numerous advantages. First, they improve productivity by speeding up tasks that are time-consuming and physically demanding, such as heavy lifting and repetitive work. Second, they enhance worker safety by reducing the risk of accidents and injuries. Robots can execute dangerous tasks and work in hazardous environments without putting human workers at risk. Lastly, automation and robotics increase accuracy and precision in construction projects. They can consistently perform measurements and calculations, minimizing errors and ensuring the quality of the final product.

Automation And Robotics In Construction:

Automation and robotics in construction, together with automated manufacturing systems and PLC electrical engineering, are crucial components of industrial automation. These technologies revolutionize various industries by enhancing productivity, improving efficiency, and ensuring precision.

In construction, automation and robotics bring numerous advantages. They speed up labor-intensive tasks, reducing project completion time. Furthermore, they enhance worker safety by performing hazardous tasks and working in dangerous environments, reducing human risk. Additionally, these technologies provide higher accuracy and improved quality, resulting in better final products.

Automated manufacturing systems play a vital role in streamlining production processes. They eliminate manual intervention, reducing errors and increasing production speed. With the ability to operate continuously, these systems optimize efficiency and minimize downtime.

PLC electrical engineering is the backbone of industrial automation. It enables the control and monitoring of machinery and processes. Its programmable nature allows for flexibility and easy customization to suit different requirements. PLCs ensure consistent and reliable operations, leading to enhanced productivity and reduced costs.

In conclusion, automation and robotics, alongside automated manufacturing systems and PLC electrical engineering, have transformed industries. These technologies improve productivity, ensure worker safety, and enhance product quality, making them indispensable components of industrial automation.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | sICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEw | |||

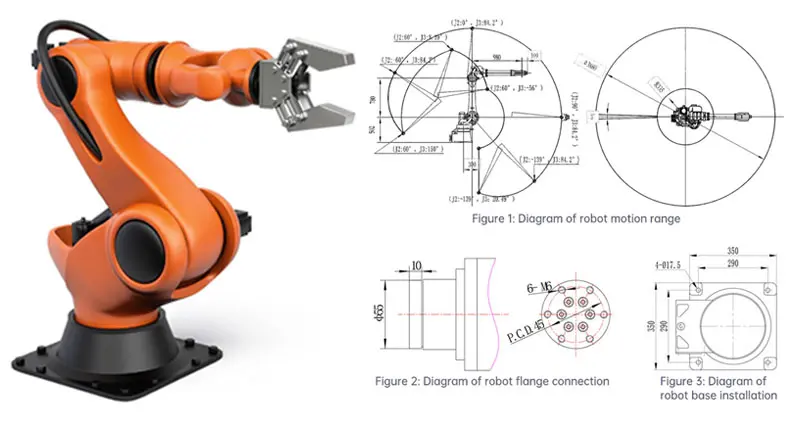

DIMENSIONAL DRAWINGS:

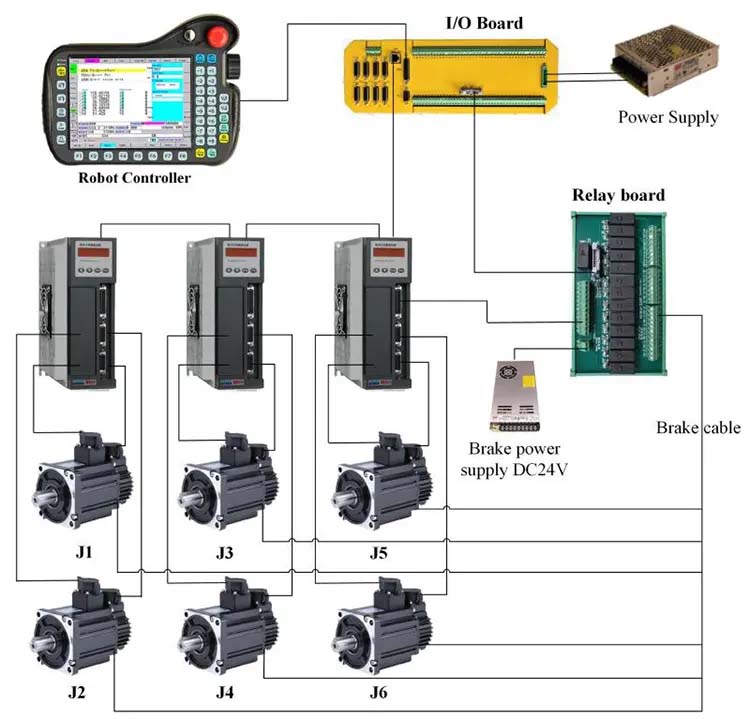

ROBOT CONTROLSYSTEM:

OUR SERVICE:

CERTIFICATIONS:

COOPERRATION PARTNER:

CONTACT US: