Use Of Robotics In Construction

Advantages of Use Of Robotics In Construction:

1,Increased Efficiency: The use of robotics in construction offers improved efficiency in various tasks. Robots can perform repetitive and labor-intensive tasks with higher speed and accuracy, reducing the time required for completion. They can work tirelessly without breaks, allowing for continuous progress and faster project timelines.

2,Enhanced Safety: Robotics provides a safer working environment in construction. By deploying robots for hazardous or dangerous tasks, human workers can be protected from potential injuries. Robots are designed to operate in challenging conditions, such as working at heights or in confined spaces, reducing the risk of accidents and ensuring worker safety.

3,Improved Precision and Quality: Robotics enables precise and consistent execution of construction tasks. With advanced sensors and control systems, robots can perform tasks with high accuracy, resulting in better quality outcomes. This level of precision minimizes errors, rework, and material wastage, leading to cost savings and higher-quality construction projects.

Use Of Robotics In Construction:

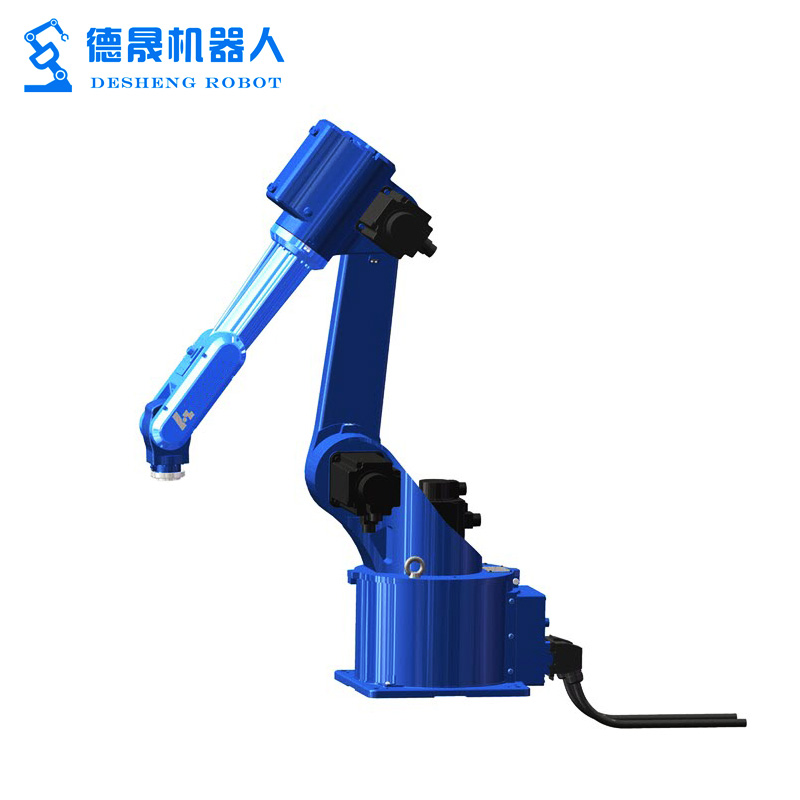

The use of robotics in construction, such as industrial arm machines like Omron SCARA and Kuka industrial robot arms, has revolutionized the industry. These robots offer several advantages in construction applications.

Firstly, industrial arm machines enable precise and efficient material handling. They can lift heavy loads, transport materials, and position them accurately, reducing the strain on human workers and enhancing productivity.

Secondly, robots like the Omron SCARA and Kuka industrial robot arm can perform repetitive and labor-intensive tasks without fatigue or errors. This leads to increased efficiency and improved consistency in construction processes, resulting in faster project completion and reduced costs.

Lastly, the integration of robotics enhances safety on construction sites. By delegating hazardous tasks to robots, human workers are protected from potential accidents and injuries. Additionally, robots can operate in challenging environments, such as confined spaces or extreme heights, ensuring safer working conditions.

Overall, the use of robotics in construction, including industrial arm machines like Omron SCARA and Kuka industrial robot arms, brings precision, efficiency, and safety to the industry, transforming the way construction projects are executed.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

APPLICATIONS:

Automated Bricklaying: Robotics is increasingly being used in construction for automated bricklaying. Robots can precisely position bricks, apply mortar, and create walls with speed and accuracy. This automation reduces labor-intensive work, increases productivity, and ensures consistent quality in bricklaying processes.

Site Surveying and Mapping: Robotics is also employed in construction for site surveying and mapping. Drones equipped with cameras and sensors can capture aerial imagery, survey the construction site, and create 3D models. This data enables accurate land measurements, project planning, and improved decision-making.

Construction Material Handling: Robots are utilized for material handling tasks in construction. They can autonomously transport and lift heavy materials, such as steel beams or concrete slabs, reducing the physical strain on workers and improving overall efficiency. Robotic material handling ensures precise placement and reduces the risk of accidents associated with manual lifting.

FEATURES:

1,Improved Efficiency: Robotics in construction enables tasks to be completed faster and more efficiently compared to traditional methods. Robots can work continuously without breaks or fatigue, allowing for accelerated construction processes and shorter project timelines.

2,Enhanced Precision: Robotics offers precise and accurate execution of construction tasks. With advanced sensors and control systems, robots can perform measurements, cuts, and installations with high precision, reducing errors and rework. This results in improved quality and consistency in construction projects.

3,Increased Safety: The use of robotics in construction enhances worker safety by automating hazardous and risky tasks. Robots can handle dangerous materials, work in hazardous environments, and perform tasks at heights, minimizing the risk of accidents and injuries. By replacing human workers in high-risk situations, robotics improves overall safety on construction sites.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: