Robotics And Automation In Manufacturing

Advantages of Robotics And Automation In Manufacturing:

1. Increased productivity: Robotics and automation in manufacturing processes can significantly increase productivity by performing tasks at a faster rate and with higher accuracy than human workers. This leads to higher production output and reduced cycle times, ultimately improving overall efficiency.

2. Improved safety: By replacing humans in dangerous or hazardous tasks, robotics and automation in manufacturing can greatly enhance workplace safety. Robots are designed to handle repetitive or physically demanding tasks without the risk of injury, reducing the number of accidents and creating a safer working environment.

3. Cost savings: Implementing robotics and automation in manufacturing can lead to significant cost savings in the long run. While initial setup costs may be high, robots can operate continuously without breaks or vacations, reducing labor costs. Additionally, automation can minimize errors and waste, resulting in better quality products and reduced material wastage.

Robotics And Automation In Manufacturing:

Robotics and automation in manufacturing have revolutionized the industry by increasing efficiency and productivity. The Kuka Kr 10 r1100 2 is a cutting-edge robot that has been widely adopted in factories worldwide. Systemantics Robotics, a leading player in the field, has seen a significant increase in its share price due to the growing demand for their advanced robotic systems. With the introduction of 7-axis robots, manufacturers can now achieve even more precise and complex tasks, further enhancing the production process.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

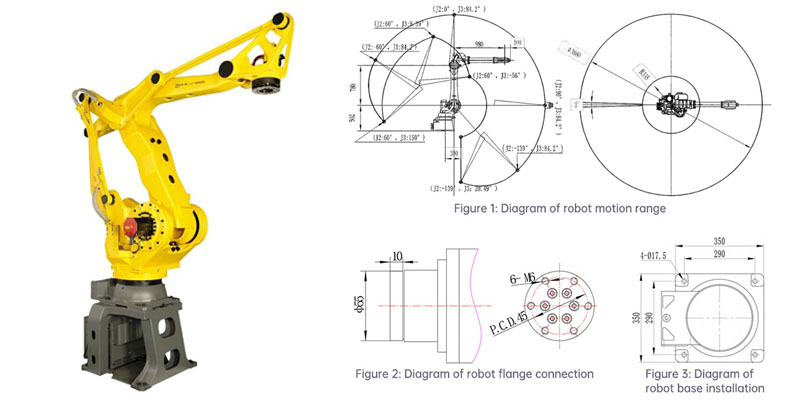

DIMENSIONAL DRAWINGS:

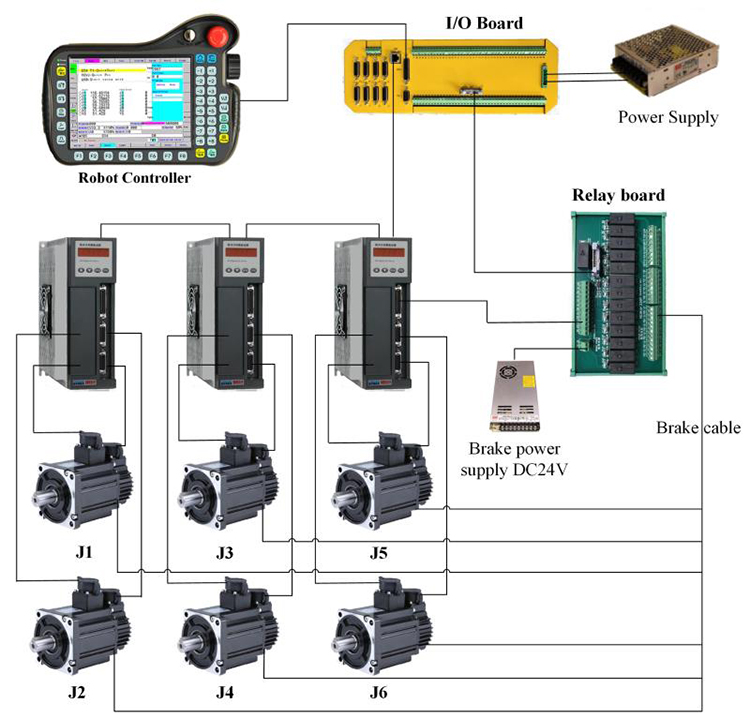

ROBOT CONTROLSYSTEM:

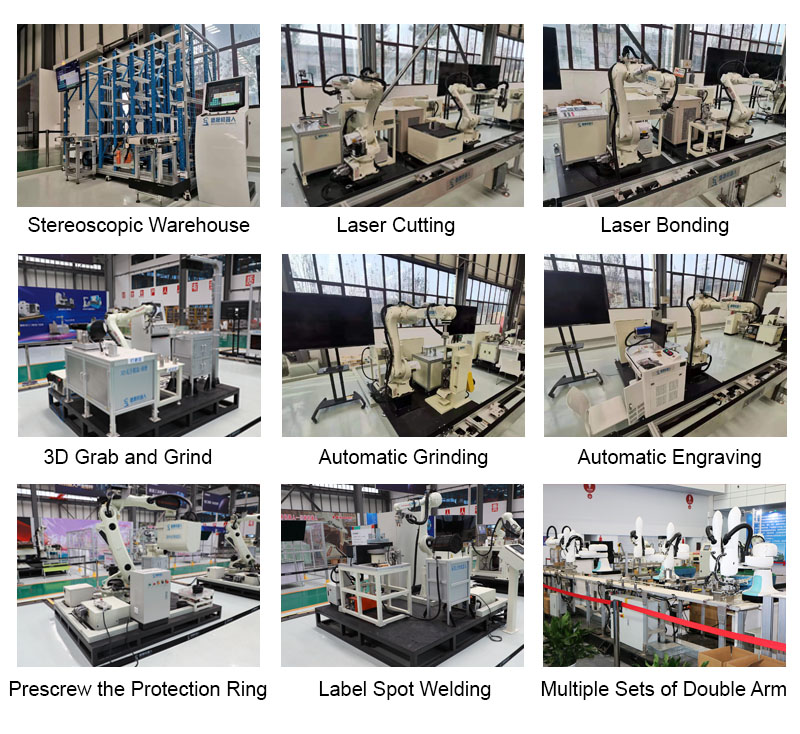

APPLICATIONS:

1. Robotic assembly: Robotics and automation are widely used in manufacturing for assembly tasks. Robots can be programmed to perform repetitive tasks with high precision and speed, leading to increased productivity and efficiency in the assembly process.

2. Material handling: Robotics and automation are also used for material handling in manufacturing. Automated guided vehicles (AGVs) and robotic arms can be used to transport materials and components within the manufacturing facility, reducing the need for manual labor and improving safety.

3. Quality control: Robotics and automation play a crucial role in quality control in manufacturing. Robots can be equipped with sensors and cameras to inspect products for defects and ensure that they meet the required quality standards. This helps to reduce the chances of human error and ensures consistent product quality.

FEATURES:

1. Increased productivity: Robotics and automation in manufacturing can significantly increase productivity by performing tasks more efficiently and accurately than human workers. Robots can work continuously without breaks or fatigue, leading to higher output and reduced production time.

2. Improved quality control: Robots are capable of performing repetitive tasks with high precision, ensuring consistent quality in manufacturing processes. They can detect and correct errors in real-time, minimizing defects and reducing the need for rework or manual inspection.

3. Enhanced workplace safety: Automation in manufacturing reduces the risk of accidents and injuries by replacing humans in hazardous or physically demanding tasks. Robots can handle heavy loads, work in extreme temperatures, and perform tasks in confined spaces, eliminating the potential dangers associated with these tasks.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: