Autonomous Industrial Robots

Advantages of Autonomous Industrial Robots:

1,Increased Efficiency: Autonomous industrial robots offer increased efficiency in manufacturing and industrial processes. These robots can operate continuously without the need for breaks, leading to improved productivity and reduced downtime. With their ability to perform repetitive and monotonous tasks accurately and consistently, they optimize workflow and minimize errors, resulting in higher efficiency and output.

2,Enhanced Safety: One of the key advantages of autonomous industrial robots is enhanced safety. These robots are equipped with advanced sensors, cameras, and safety features, allowing them to detect and avoid obstacles or hazardous situations. This helps in preventing accidents and injuries, creating a safer working environment for human workers. With their ability to handle dangerous or repetitive tasks, they also reduce the risk of worker fatigue and occupational hazards.

3,Flexibility and Adaptability: Autonomous industrial robots offer flexibility and adaptability in manufacturing processes. They can be programmed and reprogrammed to perform a wide range of tasks, allowing manufacturers to meet changing production demands quickly. This flexibility enables businesses to optimize their operations, reduce the time and cost associated with retooling, and adapt to evolving market dynamics more efficiently.

Autonomous Industrial Robots:

Autonomous industrial robots, such as the ABB SCARA robot, have become indispensable in manufacturing and industrial processes. These robots offer several advantages, including increased efficiency, versatility, and reliability.

The ABB SCARA robot, renowned for its exceptional precision and speed, is widely used for assembly, picking, and packaging tasks. Equipped with advanced sensor technology and control systems, it can autonomously perform complex motions with high accuracy, streamlining production processes and ensuring consistent quality.

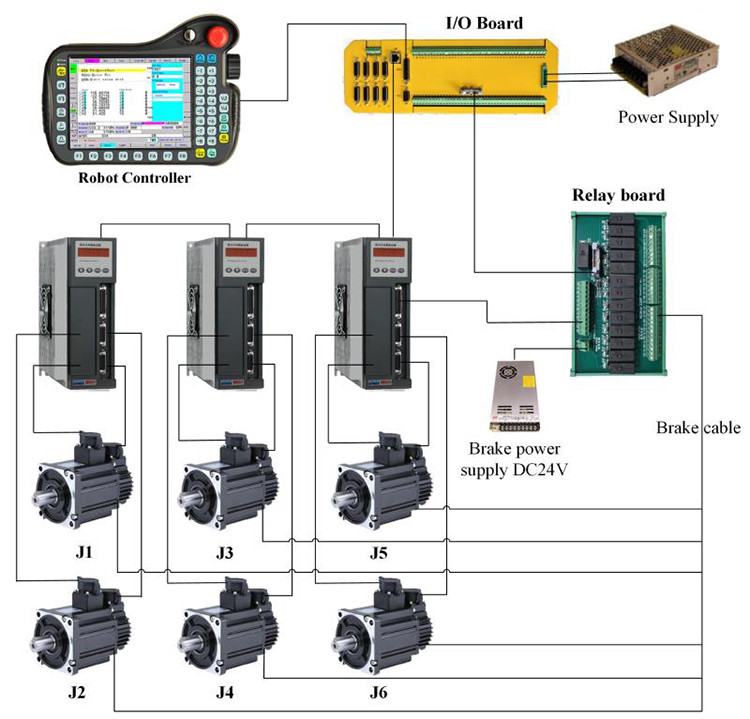

Moreover, the industrial robot controller serves as the brain behind the autonomous robot's operations. It acts as the central command center, facilitating seamless communication between the robotic system and the manufacturing environment. This controller enables easy programming, monitoring, and maintenance of the autonomous robot, enhancing operational efficiency.

Additionally, the concept of robotic energy density focuses on creating more compact and energy-efficient autonomous industrial robots. By integrating lightweight materials, optimized designs, and energy-efficient components, manufacturers can maximize performance while minimizing energy consumption.

In conclusion, as autonomous industrial robots like the ABB SCARA robot, supported by advanced controllers, continue to evolve, they enable increased efficiency and flexibility in manufacturing. Moreover, advancements in robotic energy density pave the way for more compact and environmentally friendly robotic solutions, further enhancing the effectiveness of autonomous robots in industrial settings.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

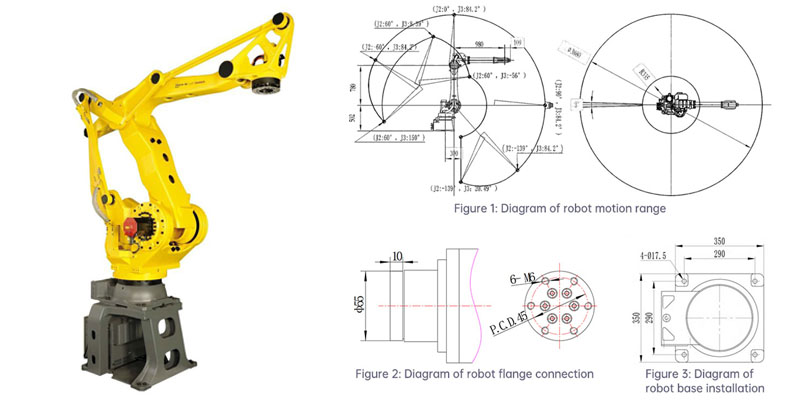

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

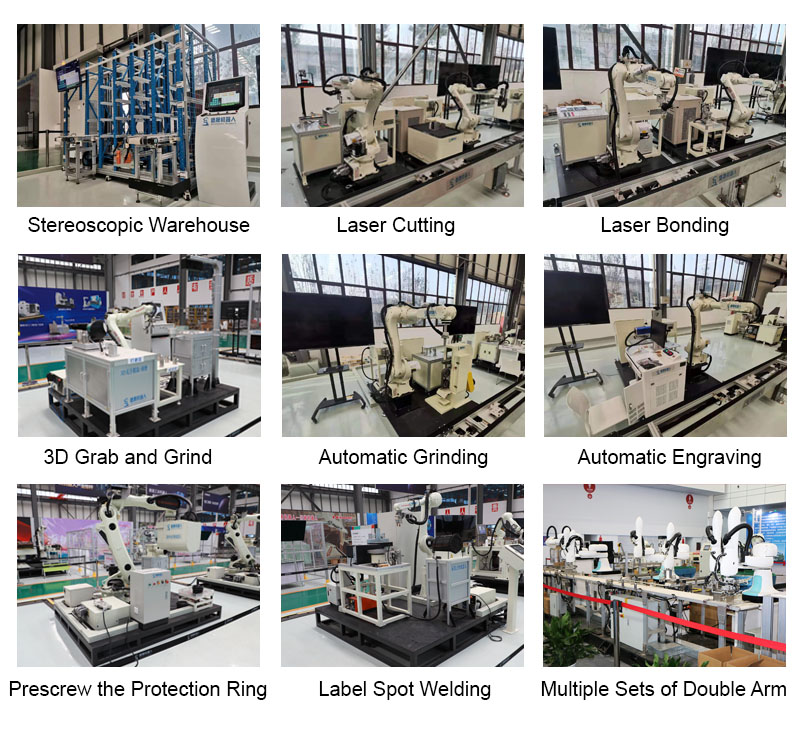

APPLICATIONS:

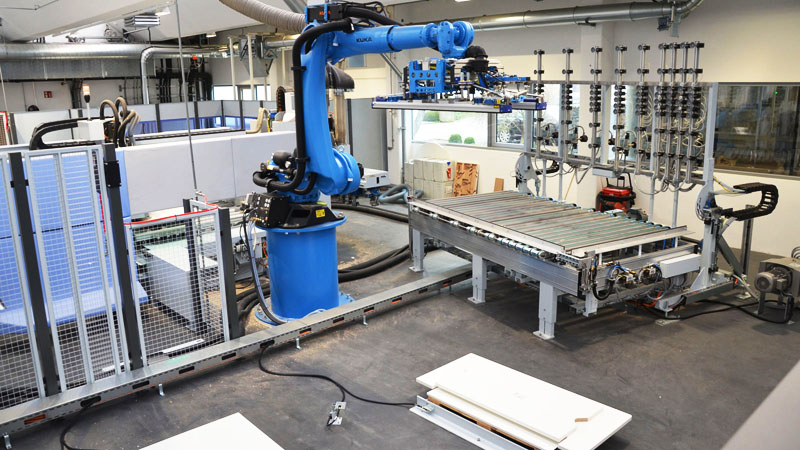

1,Warehousing and Logistics: Autonomous industrial robots are extensively used in warehousing and logistics operations. These robots can autonomously navigate through warehouses, locate and retrieve items, and transport them to designated locations. They optimize inventory management, reduce human error, and ensure efficient order fulfillment, improving overall operational efficiency in logistics and e-commerce industries.

2,Manufacturing Assembly: Autonomous industrial robots play a crucial role in manufacturing assembly processes. These robots can handle intricate and repetitive tasks with precision, such as component assembly, soldering, and quality inspection. By automating assembly processes, manufacturers can improve productivity, enhance product quality, and free up human workers for more complex and value-added tasks.

3,Agriculture and Farming: Autonomous industrial robots find applications in agriculture and farming for tasks like planting, harvesting, and crop monitoring. Equipped with advanced perception capabilities, these robots can navigate through fields, identify and remove weeds, and collect data on crop health and yield. This automation reduces labor costs, increases productivity, and enables more sustainable and optimized farming practices.

FEATURES:

1,Self-navigation: One key characteristic of autonomous industrial robots is their ability to self-navigate and operate in dynamic environments. These robots use advanced sensor technologies, such as lidar, cameras, and ultrasonic sensors, to perceive their surroundings and make real-time decisions. By autonomously mapping and navigating their environment, they can adapt to changes, avoid obstacles, and optimize their paths, enhancing efficiency and safety.

2,Decision-making: Autonomous industrial robots are equipped with intelligent algorithms and artificial intelligence capabilities, allowing them to make autonomous decisions. They can analyze data, interpret information from sensors, and adjust their actions accordingly. This decision-making ability enables them to perform tasks with accuracy, adapt to changing conditions, and interact intelligently with their environment.

3,Collaborative Capabilities: Autonomous industrial robots often possess collaborative features, allowing them to work alongside human workers safely. These robots are designed with sensors and advanced control systems that enable them to detect and respond to human presence. This collaboration between humans and robots enhances productivity, as they can work together on tasks requiring human dexterity and robot efficiency, promoting a safe and efficient working environment.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: