Robotic Additive Manufacturing

Advantages of Robotic Additive Manufacturing:

1. Increased design flexibility: Robotic additive manufacturing allows for complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. The flexibility of the robotic arm allows for the creation of unique shapes and structures, enabling greater innovation and customization in product design.

2. Improved production speed: Robotic additive manufacturing can significantly reduce the production time compared to traditional manufacturing processes. The ability to deposit material layer by layer enables faster production cycles, eliminating the need for multiple steps and reducing the overall manufacturing time.

3. Cost-effectiveness: Robotic additive manufacturing can be more cost-effective than traditional manufacturing methods, especially for low-volume or customized production. By eliminating the need for molds or tooling, robotic additive manufacturing reduces upfront costs and allows for on-demand production, minimizing inventory and storage costs. Additionally, the ability to use a wide range of materials, including recycled materials, can further contribute to cost savings.

Robotic Additive Manufacturing:

Robotic Additive Manufacturing, also known as 3D printing, has revolutionized the manufacturing industry. This innovative technology allows for the creation of complex and customized products with great precision and efficiency. One such system that has gained popularity is the Mecademic Meca500-r3 System. This compact and versatile robot can perform various tasks, such as assembly, pick and place, and quality control.

Another prominent robot in the industry is the ABB Palletizing Robot. This robot is specifically designed for palletizing and depalletizing tasks in warehouses and factories. Its advanced features, such as high payload capacity and flexible programming, make it an ideal choice for automating the palletizing process.

Industrial welding robots have also made significant contributions to the manufacturing sector. These robots are equipped with advanced sensors and programming capabilities, allowing for precise and efficient welding operations. With their ability to work in hazardous and challenging environments, industrial welding robots have greatly improved the safety and productivity of welding processes.

In conclusion, the integration of Robotic Additive Manufacturing, the Mecademic Meca500-r3 System, ABB Palletizing Robot, and Industrial Welding Robot has transformed the manufacturing industry. These robots have enhanced productivity, improved product quality, and increased workplace safety. As technology continues to advance, we can expect even more innovative and efficient robotic systems to revolutionize the manufacturing sector.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

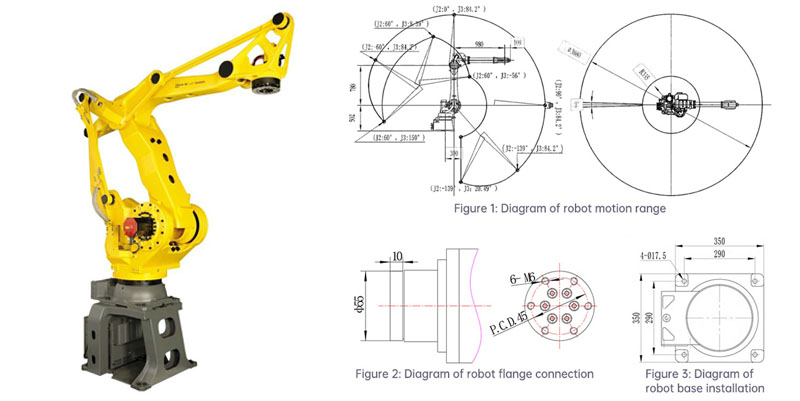

DIMENSIONAL DRAWINGS:

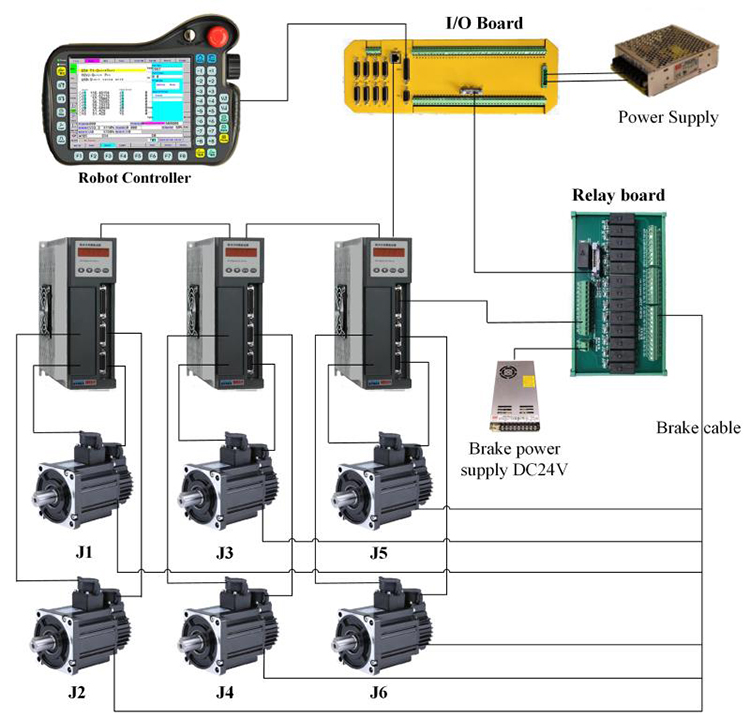

ROBOT CONTROLSYSTEM:

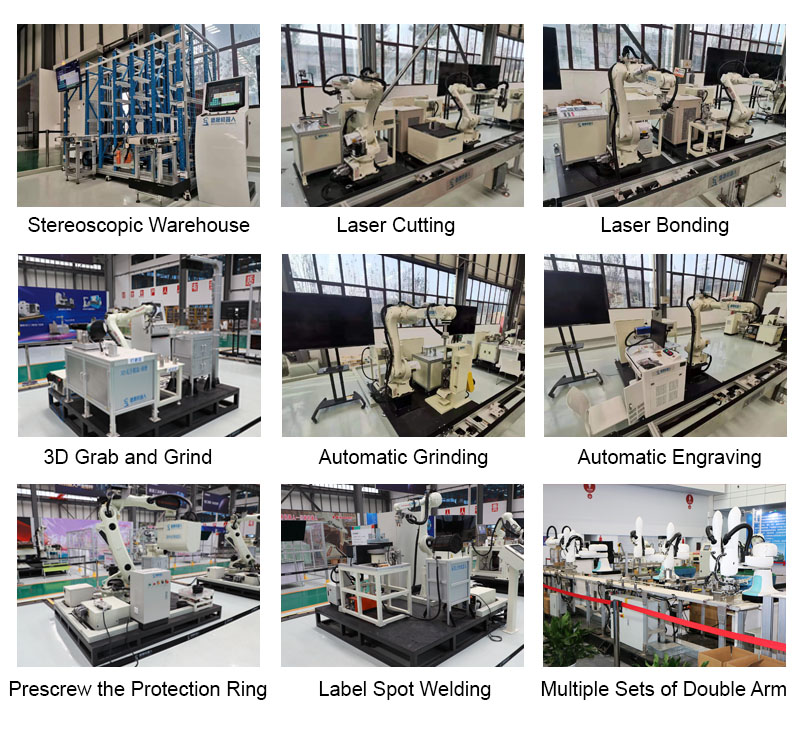

APPLICATIONS:

1. Aerospace industry: Robotic additive manufacturing is widely used in the aerospace industry to create complex and lightweight components. The ability to 3D print parts with intricate designs and reduce material waste makes it an ideal solution for producing aircraft components such as engine parts, brackets, and airframe structures.

2. Medical field: Robotic additive manufacturing is revolutionizing the medical field by enabling the production of customized implants, prosthetics, and surgical instruments. With the help of robotic systems, medical professionals can design and manufacture patient-specific implants that perfectly fit the individual's anatomy, leading to improved patient outcomes and reduced surgery time.

3. Automotive sector: Robotic additive manufacturing is increasingly being adopted by the automotive industry for various applications. It allows for the production of lightweight and complex parts, resulting in improved fuel efficiency and reduced vehicle weight. Additionally, robotic additive manufacturing enables the rapid prototyping of new designs, allowing automotive companies to iterate and test different concepts more efficiently.

FEATURES:

1. High precision: Robotic additive manufacturing processes, such as 3D printing, offer high precision in creating complex geometries and intricate designs. The robotic control allows for precise deposition of materials, resulting in highly accurate and detailed final products.

2. Customization and flexibility: Robotic additive manufacturing enables the production of highly customized products. The ability to program the robot to deposit materials in specific patterns allows for the creation of unique designs tailored to individual requirements. Additionally, the flexibility of robotic systems allows for easy adaptation and modification of the manufacturing process, making it suitable for small-scale production or prototyping.

3. Material efficiency: Robotic additive manufacturing processes are known for their material efficiency. By depositing materials layer by layer, only the necessary amount of material is used, minimizing waste. This can lead to cost savings and a more sustainable manufacturing process compared to traditional subtractive manufacturing methods.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: