Autonomous Aerospace Robots Solution Series

Autonomous Aerospace Robots Solution Series:

The advantages of the Autonomous Aerospace Robots Series are enhanced efficiency and productivity, improved safety, and cost savings. These robots autonomously perform tasks, reducing errors and minimizing downtime. With advanced sensors and AI technology, they can navigate and operate in complex and hazardous environments, ensuring safety for human workers. By automating repetitive and labor-intensive tasks, they reduce labor costs and contribute to increased production output, saving time and money for aerospace companies.

Please Contact Us For Detailed Technical Parameters.

Autonomous Aerospace Robots Solution Series:

Autonomous Aerospace Robots Series, developed by Industrial Automation M Sdn Bhd, offers cutting-edge industrial control technology and PLC programming solutions. Autonomous Aerospace Robots Solution Series in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.This series of robots brings numerous advantages to the aerospace industry, enhancing productivity and efficiency. Equipped with advanced sensors and AI technology, these robots can autonomously perform complex tasks, ensuring improved safety for workers. With their precise and reliable performance, they optimize manufacturing processes, reducing errors and downtime.

Industrial Automation M Sdn Bhd, a leading PLC programming company, has developed these robots to meet the specific needs of aerospace companies. They incorporate state-of-the-art industrial control technology, providing seamless integration with existing systems. The robots from this series contribute to cost savings by automating repetitive and labor-intensive tasks, resulting in increased production output and faster turnaround times.

Overall, the Autonomous Aerospace Robots Series from Industrial Automation M Sdn Bhd, with their advanced PLC programming and industrial control technology, provide a reliable and efficient solution for aerospace companies, driving productivity, safety, and cost-effectiveness in the industry.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | sICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEw | |||

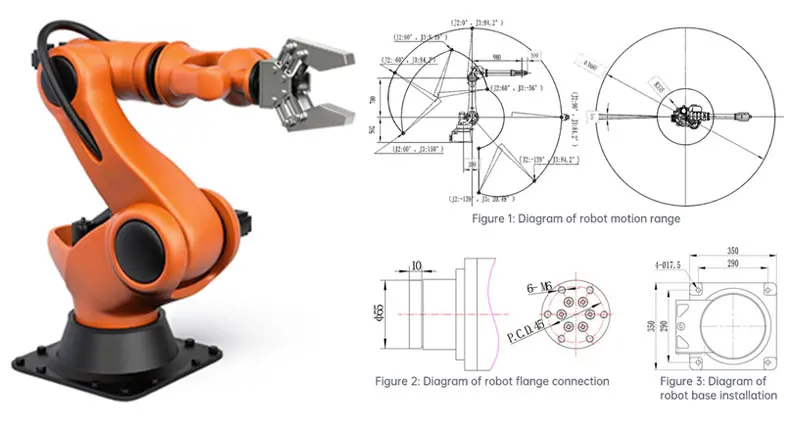

DIMENSIONAL DRAWINGS:

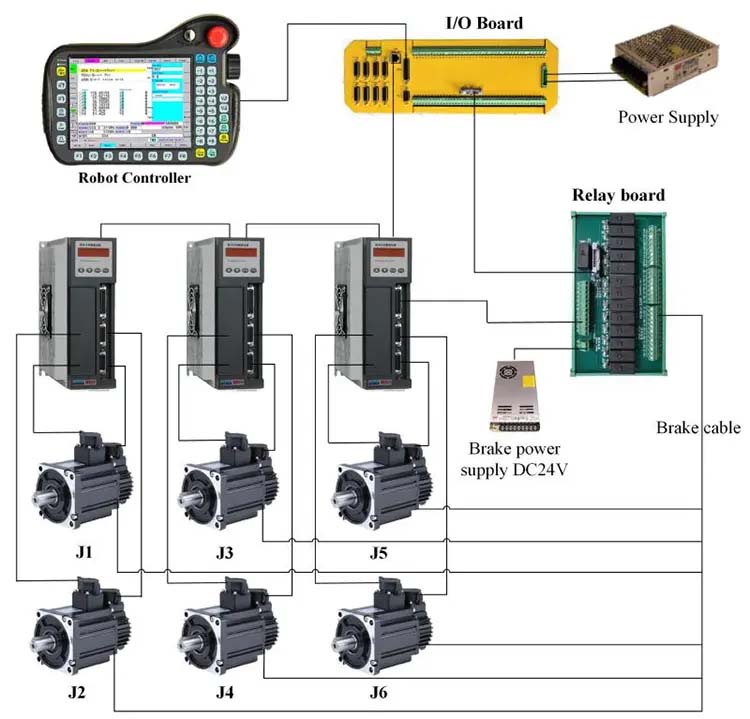

ROBOT CONTROLSYSTEM:

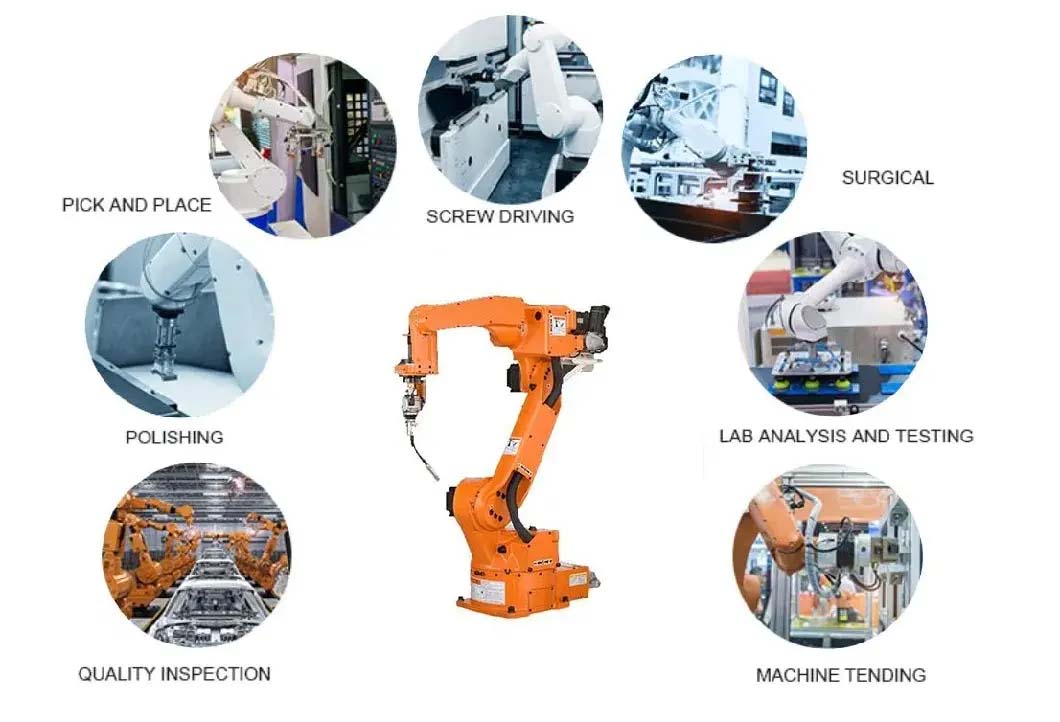

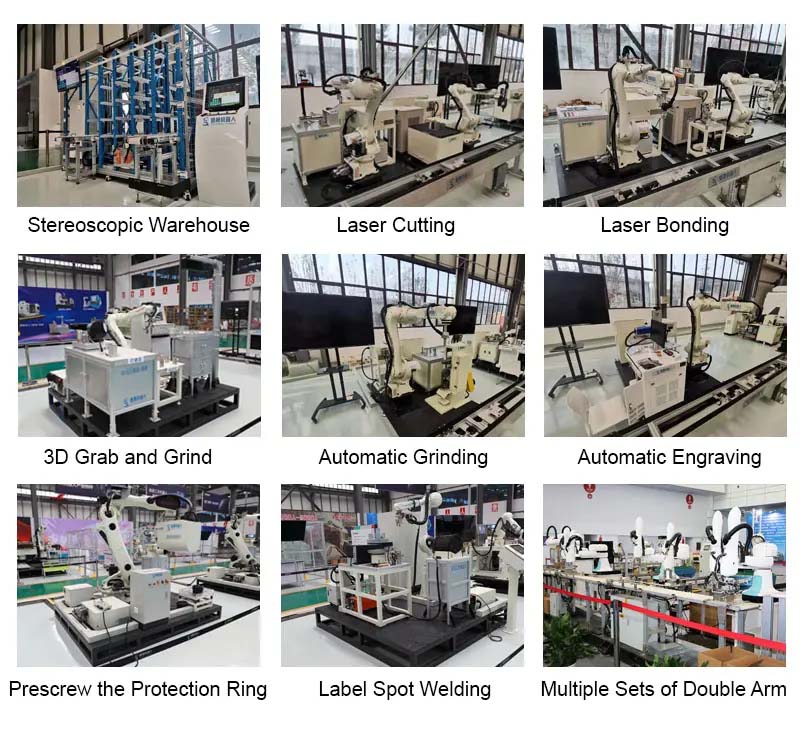

APPLICATIONS:

FEATURES:

1,Advanced autonomy: These robots have high-level autonomy, allowing them to perform tasks without the need for constant human intervention. They can navigate, operate, and adapt to complex aerospace environments, making them highly efficient and reliable.

2,Versatile functionality: The Autonomous Aerospace Robots Series is designed to handle a wide range of tasks in the aerospace industry. Whether it is inspections, maintenance, or logistics, these robots are capable of performing various functions, increasing their versatility and adaptability.

3,Intelligent decision-making: Equipped with AI technology and advanced sensors, these robots can make intelligent decisions and adjust their actions in real-time. They can analyze data, anticipate obstacles, and optimize their performance, making them highly precise and efficient in executing tasks.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

CONTACT US: