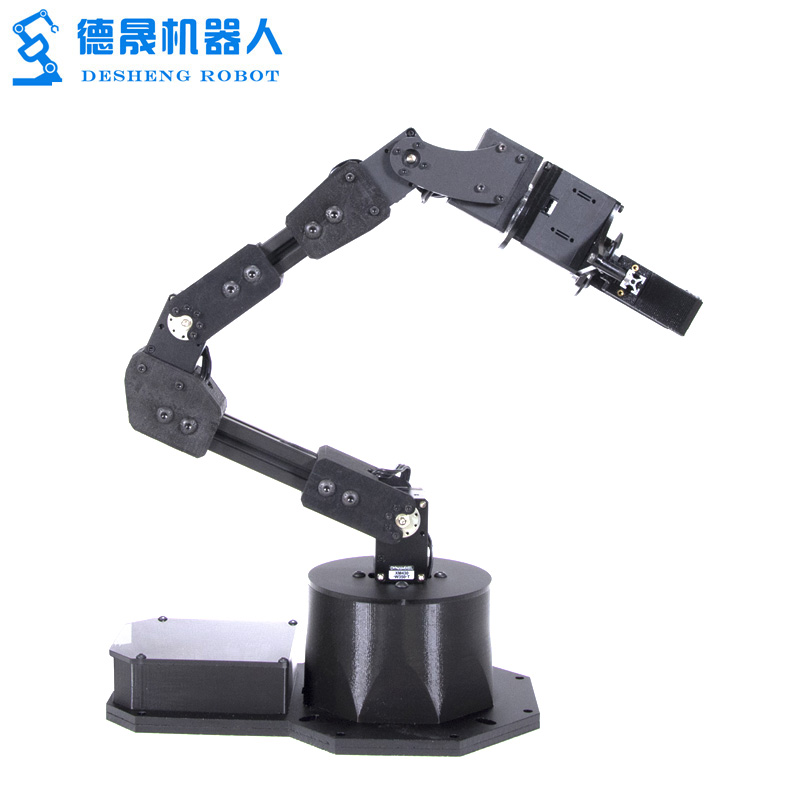

Carbon Block Task Assignment Robots

Advantages of Carbon Block Task Assignment Robots:

1,Enhanced Efficiency: Carbon Block Task Assignment Robots' advanced automation technology allows for improved efficiency in carbon block production. The robots can handle complicated tasks while working collaboratively with other robots, ensuring that the production process is streamlined, faster, and more efficient.

2,Increased Precision and Accuracy: The advanced programming and high-precision sensors used in Carbon Block Task Assignment Robots ensure uniformity in the production of carbon blocks. The robots can measure and position the blocks accurately, leading to improved product quality and reduced waste.

3,Improved Safety: The use of automation technology in Carbon Block Task Assignment Robots minimizes human contact with heavy machinery during the production process, reducing risks associated with potential hazards and ensuring a safer work environment.

Carbon Block Task Assignment Robots:

Carbon Block Task Assignment Robots are a prime example of how robotics technology continues to transform various sectors. With advanced automation technology, these robots offer increased efficiency, accuracy, and safety in carbon block manufacturing. The Carbon Block Task Assignment Robots' capabilities are attributed to the contributions of Joseph Engelberger, who is considered the father of robotics. The robots use the latest Scara Robot Arm technology, enhancing precision and consistency in their tasks. As the demand for efficient and sustainable manufacturing processes increases, new robotics technology will continue to emerge, with projections indicating exciting developments in 2022. Overall, the implementation of Carbon Block Task Assignment Robots has proven to be a game-changer in the carbon block manufacturing process, further involving the need for automation technology in various industries.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

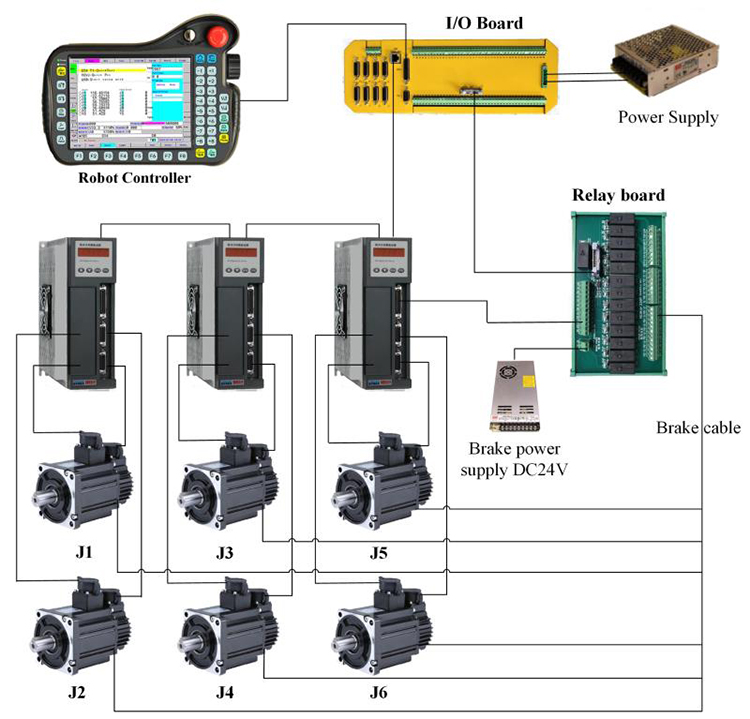

ROBOT CONTROLSYSTEM:

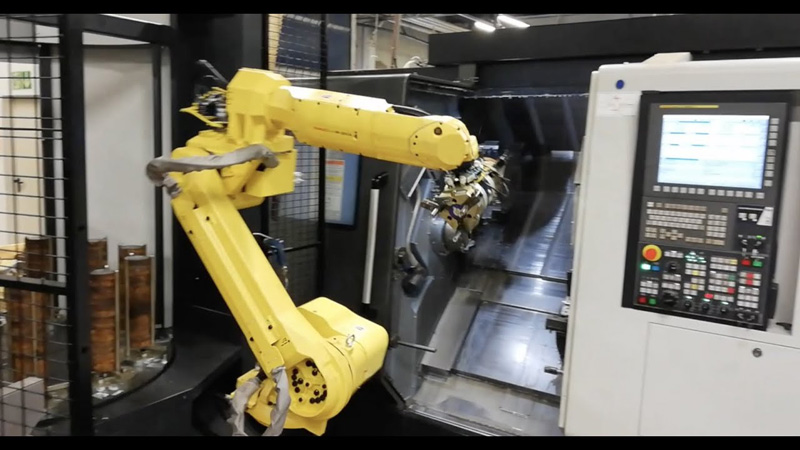

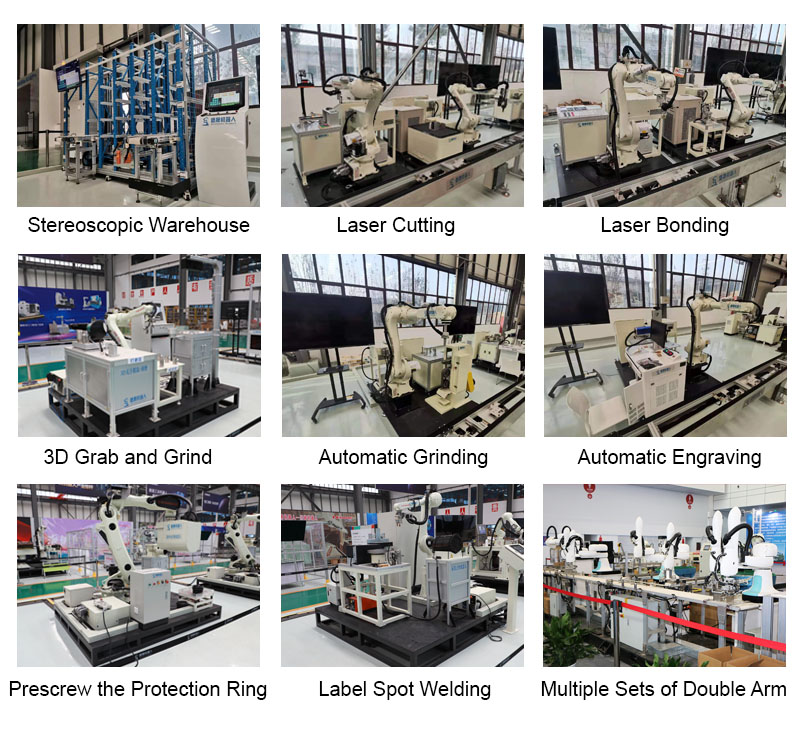

APPLICATIONS:

1,Manufacturing: Carbon Block Task Assignment Robots can be used in various manufacturing processes that use carbon blocks. The robots can be programmed to automatically transport and allocate the carbon blocks to different stages of the manufacturing process, improving efficiency and reducing labor costs.

2,Construction industry: The robots can also be used in the construction industry in applications such as the installation of carbon-based materials for insulation or for sequestration of carbon in building materials. The robots can be programmed to transport and allocate the materials to the required locations within the construction site, reducing manual labor and improving efficiency.

3,Energy industry: Carbon Block Task Assignment Robots can be used in the energy industry, where carbon blocks are used in various processes such as carbon capture, utilization, and storage. The robots can be programmed to automatically allocate the carbon blocks to different stages of the process, improving the efficiency and safety of the process.

FEATURES:

1,Precision and accuracy: Carbon Block Task Assignment Robots are designed to be precise and accurate in their allocation of tasks, ensuring reliable and consistent operation. The robots can be programmed to allocate carbon blocks to specific locations within a process or a site, ensuring optimal use of the blocks and reducing waste.

2,Increased efficiency: The robots can automate the task allocation process, which helps improve efficiency by reducing the time it takes to allocate carbon blocks to specific tasks. This leads to an improvement in productivity and reduces operational costs.

3,Safety: Carbon Block Task Assignment Robots can be used to perform tasks that would otherwise present safety risks for human workers. The robots can handle heavy or hazardous materials, ensuring worker safety and reducing the risk of work-related injuries. This increased safety also helps to reduce downtime, ensuring that tasks are completed on time and within budget.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: