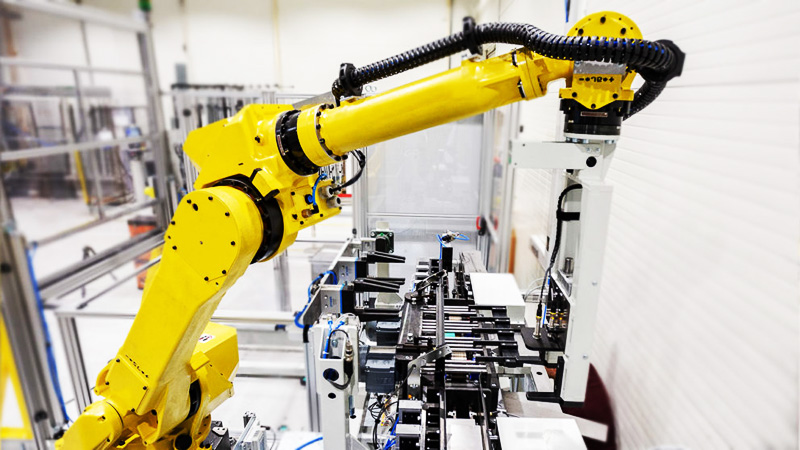

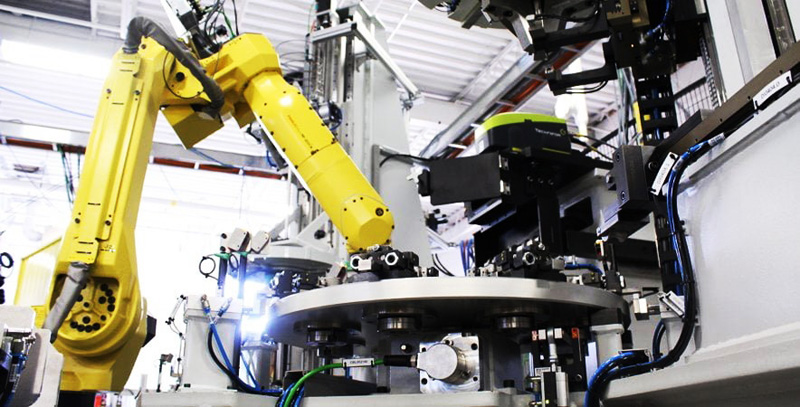

Robots For Car Body Welding

Advantages of Robots For Car Body Welding:

1,Improved precision: Robots for car body welding can provide precise welds and placements of parts, reducing the incidence of errors and improving the overall quality of the final product. Automotive manufacturers in the world's largest automobile industry are increasingly relying on robots for car body welding production to ensure precision and consistency in the welding process.

2,Faster production cycles: Robots can perform welding tasks more quickly and consistently than humans, reducing the production cycle time and increasing output levels. However, implementing a fully automated production line involves considering the advantages and disadvantages of the automated production line, as seen in the Automated Production Line Advantages and Disadvantages.

Robots For Car Body Welding:

The world's largest automobile industry is increasingly turning to automated production lines to increase efficiency and output levels. However, it is essential to consider the potential advantages and disadvantages of the automated production process. As noted in Automated Production Line Advantages and Disadvantages, such systems can significantly improve production times, output rates, and product quality.

Furthermore, the shift in the automobile assembly line worker job description, away from repetitive, hazardous tasks and towards supervisory, problem-solving, and maintenance roles, has enhanced worker safety in the welding process. The use of automated car body welding robots, which provide greater precision and consistency, reduces the risk of accidents and injuries in the workplace.

Overall, the implementation of automated production processes and robotics technology in the automobile industry presents numerous opportunities for improved production efficiency, quality, and worker safety. It is essential to consider the potential benefits and limitations of automation to maximize its advantages and minimize its drawbacks.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

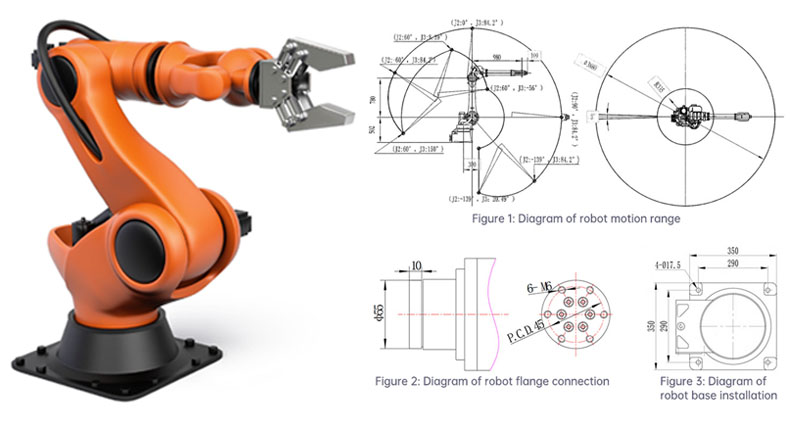

DIMENSIONAL DRAWINGS:

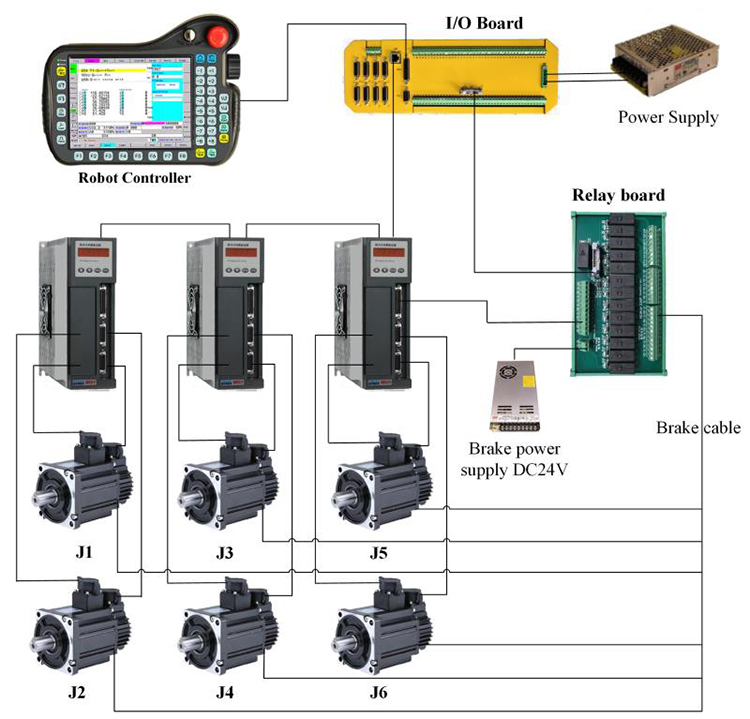

ROBOT CONTROLSYSTEM:

APPLICATIONS:

1,Improved efficiency and productivity: Robots for car body welding can work quickly and consistently, which can significantly improve production efficiency and productivity.

2,Reduced labor costs: By using robots for car body welding, manufacturers can reduce the need for manual labor in the welding process. This can result in significant cost savings over time.

3,Enhanced quality control: Welding robots can be programmed to perform precise and consistent welds every time, which can help to ensure a high level of quality control and minimize the risk of defects or errors in the finished product.

FEATURES:

1,Programmability: Robots for car body welding can be programmed to perform specific tasks with a high degree of accuracy and precision. This flexibility allows manufacturers to customize the welding process for different car models and production runs.

2,High degree of automation: Robotic welding systems can operate independently, requiring minimal human intervention. This can reduce the risk of errors or accidents caused by human error, as well as increase overall production efficiency.

3,Versatility: Welding robots can be used for a variety of welding processes, including spot welding, arc welding, and laser welding. This versatility makes them ideal for use in car body manufacturing, where a range of welding techniques may be required depending on the specific car model and design.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: