Fully Automated Assembly Line

Advantages of Fully Automated Assembly Line:

1, Improve production efficiency and quality: An auto assembly line is a fully automated assembly line that has a high degree of mechanization and automation, can complete a large number of tasks in uninterrupted production, reducing the time and energy required for manual operation, while improving production quality and consistency.

2, Reduce costs: In terms of the long-term cost of input and operation of equipment and automation systems, an auto assembly plant like Auto Assembly Plant Mexico can benefit from fully automated assembly line, help reduce costs through mass production and full use of resources, and is not affected by the labor market, reducing the cost of hired labor.

3, Reduce the interference of human factors: In the operation of an automatic assembly line, only a small number of personnel are needed for supervision and maintenance, reducing personnel misoperation and other unnecessary human factors interference, further improving production efficiency and quality.

Fully Automated Assembly Line:

Fully automated assembly lines have become increasingly popular in modern manufacturing facilities due to their numerous advantages. An auto assembly line is a prime example of such a mechanism, allowing for the completion of a large number of tasks through reduced manual operations and increased automation, hence improving its consistency and quality output. Auto assembly plants across the world, such as the Auto Assembly Plant Mexico, have been embracing this technology in efforts to optimize their respective manufacturing processes. By doing so, they help reduce the cost of hired labour, enabling them to take advantage of mass production methods while simultaneously utilizing available resources to reduce overall cost implications. Automatic assembly lines are highly mechanized and perform tasks according to preset rules. The use of such a technology is especially important in achieving high-quality output and meeting zero-defect objectives by minimizing human factor interference.

PARAMETERS:

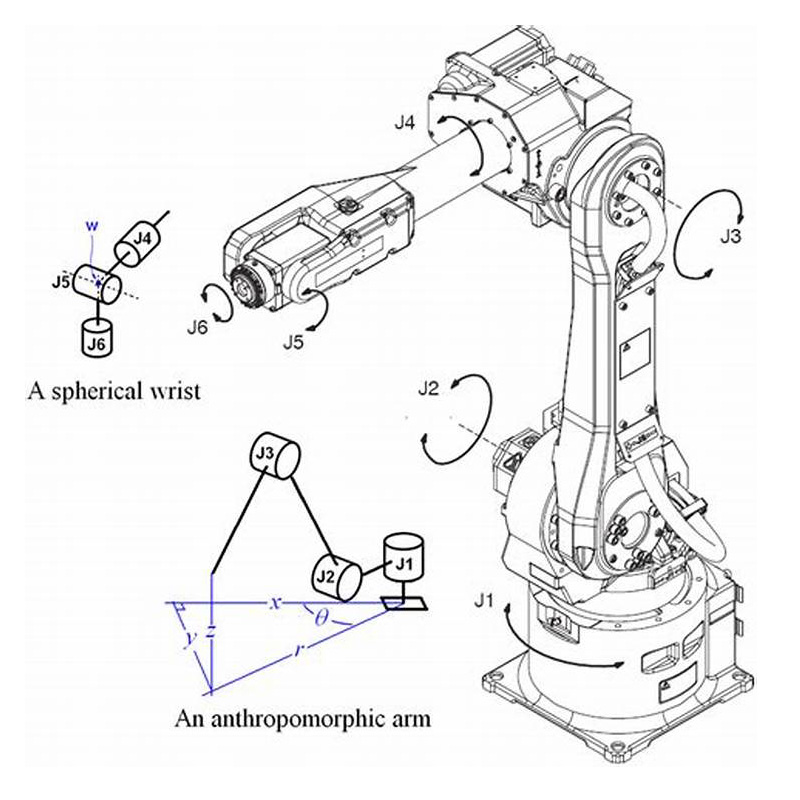

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

APPLICATIONS:

1. Automobile production: Automobile manufacturers can use fully automated assembly line to manufacture different components and accessories of automobiles, thereby improving production efficiency and quality.

2, Electronic manufacturing: Electronic manufacturing companies can use fully automated assembly line to produce electronic equipment, such as mobile phones, tablet computers, TV sets, etc., to improve production efficiency and reduce costs.

3, Food processing: food production enterprises can use fully automated assembly line for food packaging, canning, foil packaging and other processing, and to ensure product quality and health and safety.

4, Pharmaceutical production: pharmaceutical companies can use fully automated assembly line for drug production and packaging, avoiding the impact of human error, while ensuring the quality and health safety of drugs.

FEATURES:

1,High degree of automation: Fully Automated Assembly Line achieves a high degree of mechanization and automation, reduces the time and cost of manual operation, and maximizes production efficiency and quality.

2,Accurate and efficient equipment: In the Fully Automated Assembly Line, the consistency and accuracy of equipment execution are high, reducing errors and defects caused by human factors, and helping to ensure product quality and production efficiency.

3,Flexible and changeable: Fully Automated Assembly Line can be flexibly adjusted and changed according to product and production needs, and can adapt to the needs of different production processes and product types.

4,High traceability: Fully Automated Assembly Line can realize the monitoring and recording of every step in the production process, fine management and traceability of the production process, and help to improve production quality and track product quality.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: