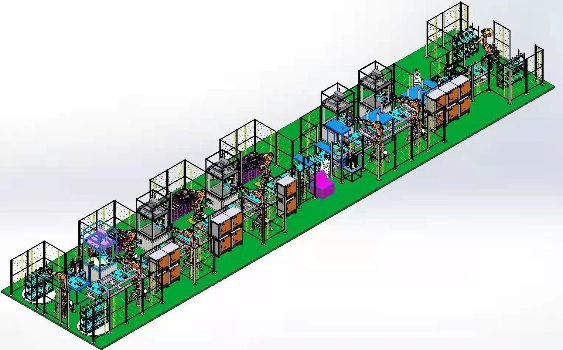

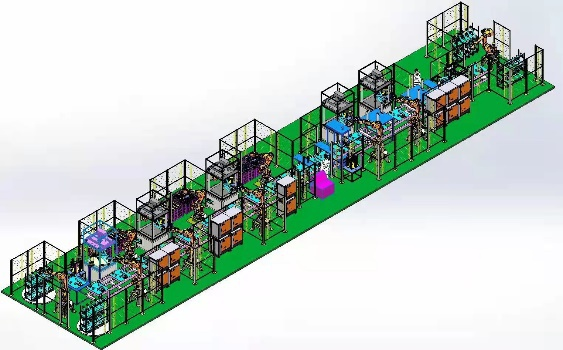

Automatic Assembly Line For V-Shape Thrust Rod Assembly

DSVT-60AL

Compatible product categories: more than 10;

Product assembly weight: ≤ 90 kg.

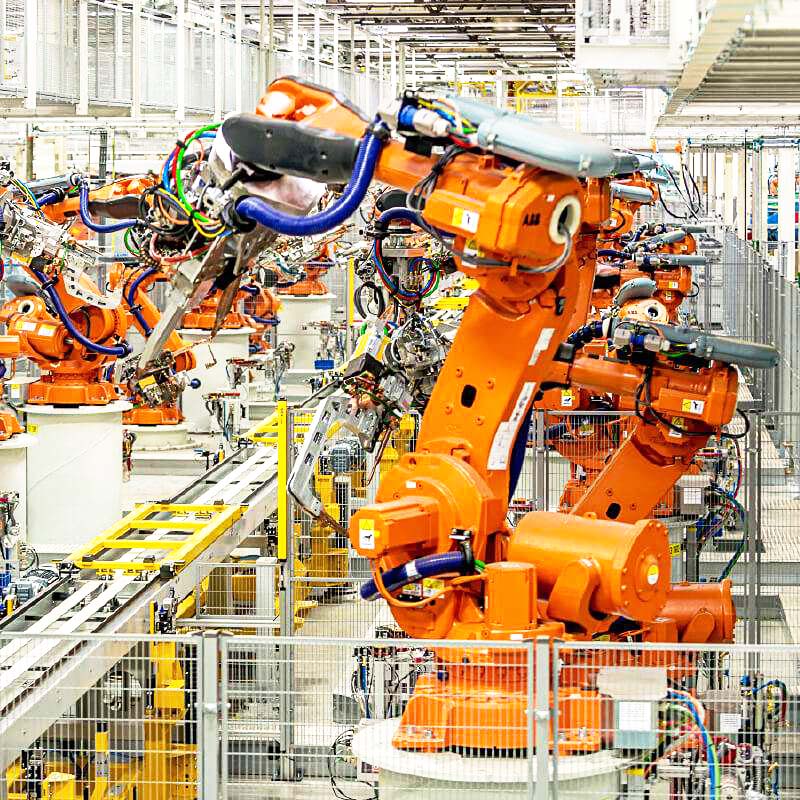

1. Increased Efficiency: An automatic assembly line for V-shape thrust rod assembly can significantly improve production efficiency. With automated processes, tasks that would otherwise require manual labor can be completed at a much faster rate. This allows for higher output and reduced production time, ultimately leading to increased productivity.

2. Consistent Quality: Automation ensures a higher level of consistency and accuracy in the assembly process. By eliminating the potential for human error, the automatic assembly line can consistently produce thrust rods that meet the required specifications and quality standards. This leads to a more reliable and consistent product, reducing the likelihood of defects and customer complaints.

3. Cost Savings: Implementing an automatic assembly line can result in significant cost savings for manufacturers. By reducing the need for manual labor, companies can save on labor costs and potentially reallocate resources to other areas of the production process. Additionally, automation can help minimize material waste and optimize the use of resources, further reducing costs in the long run.

This assembly line is a flexible automatic production line, which realizes automatic assembly of V-type thrust rod assemblies for heavy trucks by using six-axis robots, 2D vision systems, 3D vision systems, and servo presses. It is compatible with the automated production of many kinds of V-type thrust rod and other auto parts assembly products. The line is equipped with manual operation positions to meet the production of special structure thrust rod assemblies. The assembly line has a high degree of flexibility and is the first of its kind in China.

DSVT-60AL

Compatible product categories: more than 10;

Product assembly weight: ≤ 90 kg.

APPLICATIONS:

1. Increased efficiency: An automatic assembly line for V-shape thrust rod assembly can significantly improve the efficiency of the production process. With automated machines and equipment handling the assembly tasks, the line can operate at a faster pace, reducing the time required to produce each thrust rod. This can lead to higher production volumes and increased overall productivity.

2. Consistent quality: Automation in the assembly line ensures a high level of consistency and accuracy in the assembly of V-shape thrust rods. Automated machines can precisely position and fit the components together, reducing the chances of human error. This results in a consistent and reliable quality of the thrust rods, meeting the required specifications and standards consistently.

3. Cost savings: Implementing an automatic assembly line can lead to cost savings in the long run. Although the initial investment may be higher, the reduced labor costs and increased efficiency can result in significant savings over time. The automated assembly line can also minimize the need for rework or repairs due to human errors, further reducing costs associated with quality issues.

FEATURES:

1. High Efficiency: The automatic assembly line for V-shape thrust rod assembly is designed to maximize productivity and efficiency. It is capable of performing multiple assembly tasks simultaneously, reducing the overall production time and increasing output.

2. Precision and Accuracy: The assembly line is equipped with advanced sensors and robotics technology, ensuring precise and accurate assembly of the V-shape thrust rod. This eliminates the possibility of human error and ensures consistent quality of the final product.

3. Flexibility and Adaptability: The assembly line is designed to be flexible and easily adaptable to different assembly requirements. It can be programmed to accommodate various sizes and specifications of V-shape thrust rods, allowing for easy customization and production of different models.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

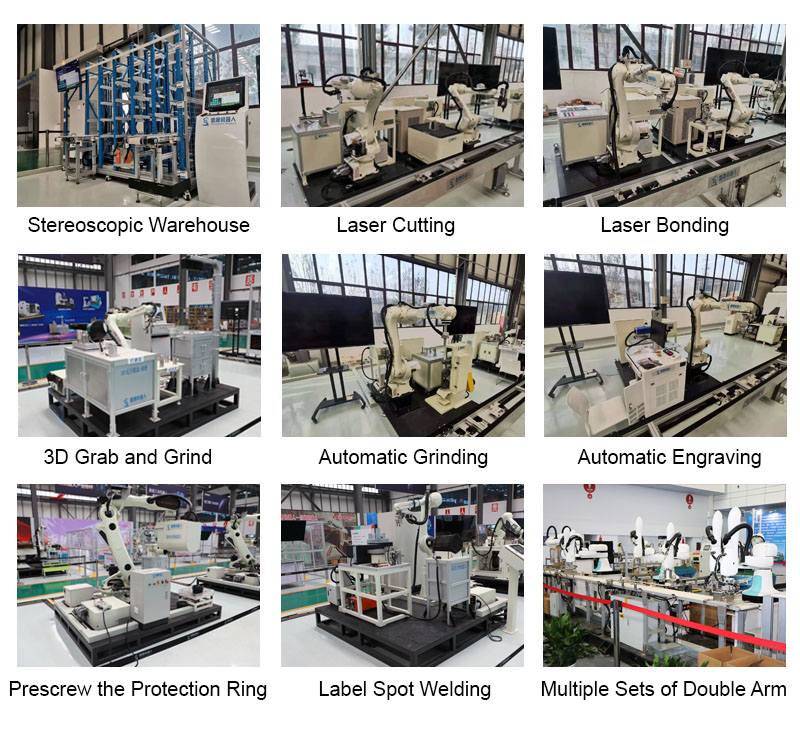

MORE PRODUCTS:

CONTACT US: