Automated Collaborative Factory Robots

Advantages of Automated Collaborative Factory Robots:

1,The use of automated processes, such as those implemented by German Car Companies, can improve production efficiency significantly. Robots are capable of performing various tasks on the production line, reducing production cycles and increasing efficiency.

2,According to the latest developments in Autonomous Vehicle News, the use of automated technology can also help to improve the production environment in addition to the benefits of freeing workers from repetitive tasks and dangerous workplaces. This can help to improve the working environment and employee health, making it a priority for many industries, including German Car Companies.

3,The implementation of automated processes with the support of Automotive Parts Suppliers can reduce production costs in addition to increasing production efficiency. Robots can perform multiple tasks that existing employees may not be able to perform with the same precision and accuracy, leading to cost savings. This is particularly important for German Car Companies and other industries that need to prioritize cost reductions while maintaining high-quality standards.

Automated Collaborative Factory Robots:

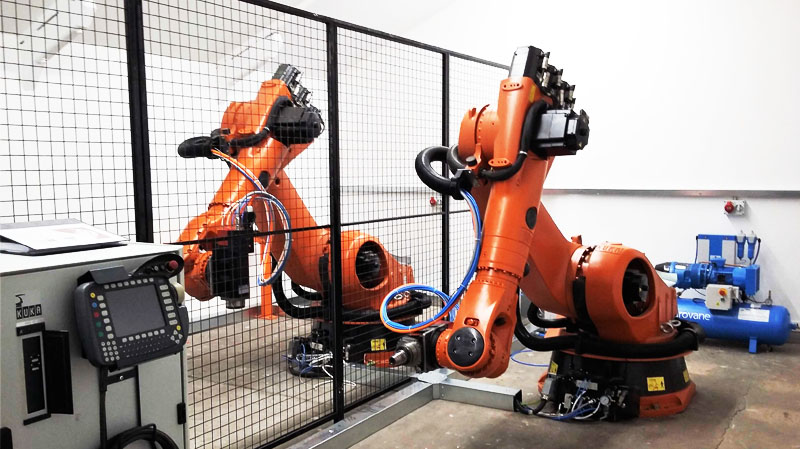

Automated Collaborative Factory Robots are transforming production lines worldwide, and German Car Companies are no exception. The latest news in Autonomous Vehicle News highlights the partnership between German Car Companies and Automotive Parts Suppliers in implementing the latest in automated robotic technology. Through their collaboration, these companies are reducing production cycles, improving accuracy and precision, and maintaining high standards of quality. The use of Collaborative Robots allows workers to be freed from repetitive and dangerous tasks, leading to a safer and healthier work environment. The efficiency and cost savings from automation are essential for the automobile industry to remain competitive while also providing high-quality vehicles to customers. As the automotive industry heads towards electronic and autonomous vehicles, there is no doubt that the continued partnership between German Car Companies and Automotive Parts Suppliers will lead the field towards a more efficient and technologically advanced future.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

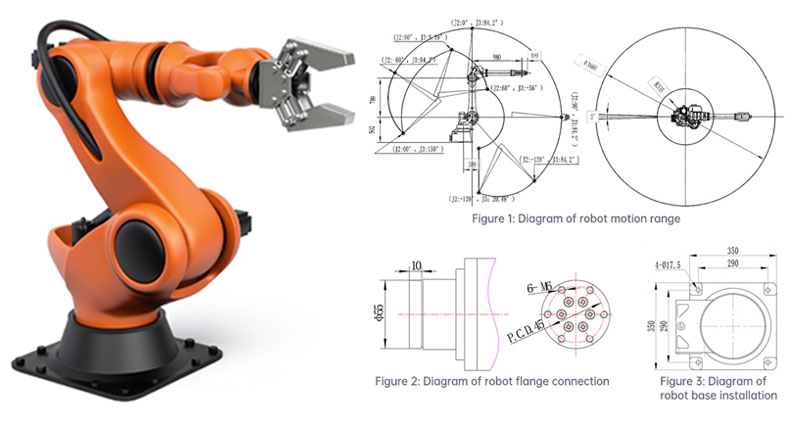

DIMENSIONAL DRAWINGS:

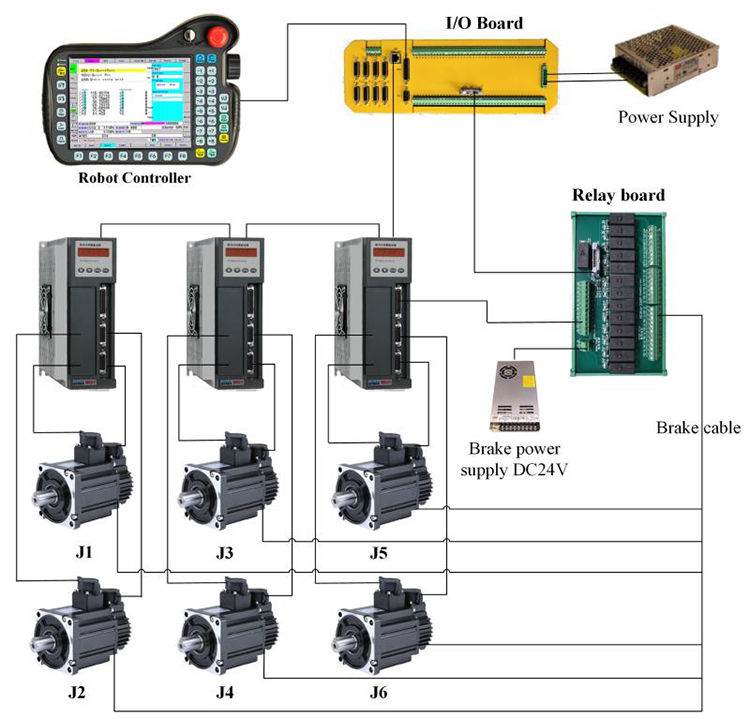

ROBOT CONTROLSYSTEM:

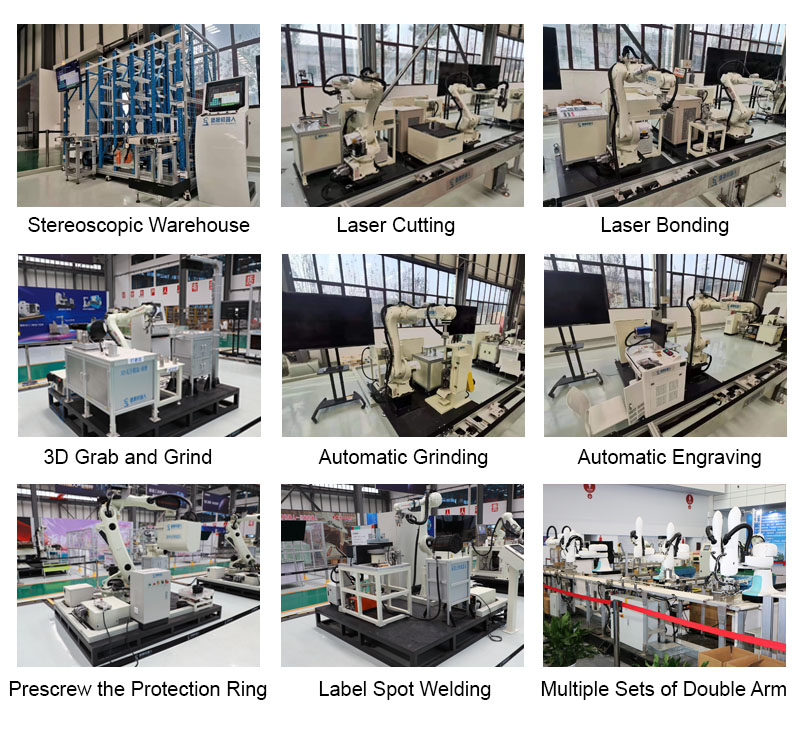

APPLICATIONS:

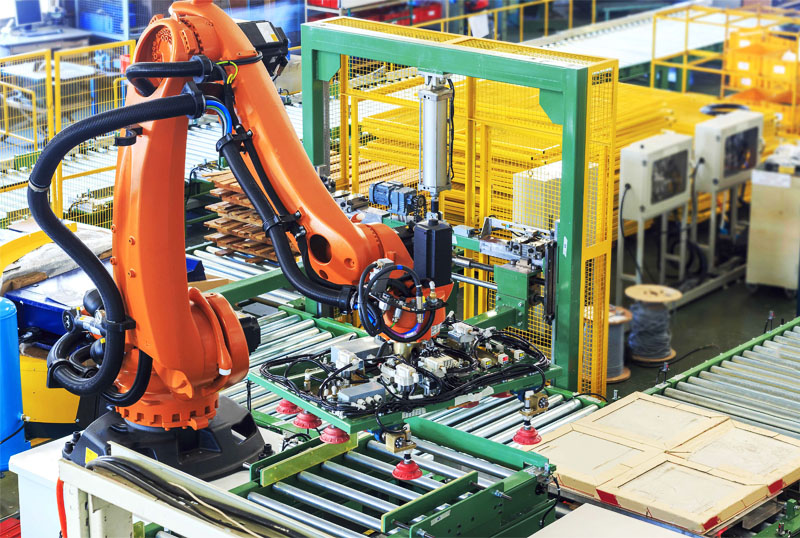

1,Manufacturing: in production, palletizing robots can be used to stack and float heavy elements, finished merchandise and uncooked substances. inside the car industry, as an example, they might vicinity frames, engines, and unique important components to hurry up manufacturing and growth manufacturing performance.

2,Logistics and warehousing: within the logistics and warehousing industry, palletizing robots may be used to package deal, kind and set up items. for example, devices may be stacked thru using robots and moved to the proper region constant with unique orders. this permits logistics businesses and storage facilities to manipulate and skip massive volumes of goods more efficiently and decrease human beneficial useful resource fees.

3,Food and beverage commercial enterprise organization: palletizing robots are usually used within the meals and beverage industry to stack and bypass meals cans, bottles, bins and luggage. the robot can brief and correctly %. those products into packing containers or pallets. this automatic technique can reduce the amount of labor for personnel, thereby growing production basic overall performance and reducing human errors.

FEATURES:

1,Immoderate precision: palletizing robotic can be operated in step with very specific preset parameters, as a end result ensuring a excessive degree of accuracy in stacking and arranging items. the robot's excessive-precision operation nearly gets rid of stacking problems due to human errors.

2,Programmable: palletizing robots for shipment stacking are programmable, due to this that they're able to customize their way of operation to in form different sorts and sizes of cargo. this makes them extra bendy and capable of meet wonderful stacking dreams in a spread of industries.

3,Excessive safety: palletizing robots carry out with a immoderate degree of safety. via using superior sensor generation and tracking structures, the robotic is able to avoid collision with any transferring individual or exclusive obstacles, consequently ensuring a high stage of safety in the course of use.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: