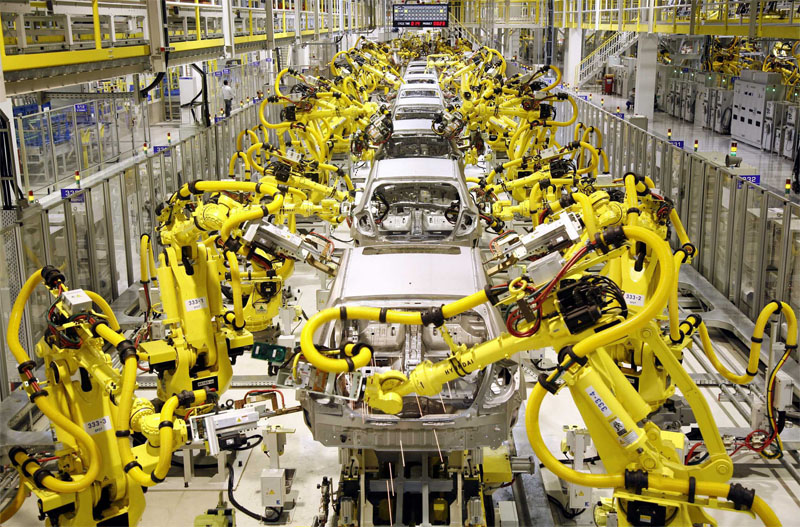

Automated Automotive Assembly Line

Advantages of Automated Automotive Assembly Line:

1,Increased production efficiency: Automated assembly lines, such as Auto Assembly Line Photos, allow for increased production efficiency with the use of machines and robotics to complete tasks that would otherwise require manual labor. The machines can work 24/7 without the need for breaks, which results in a higher output rate within a shorter time frame.

2,Improved quality control: Automated assembly lines, such as Automated Assembly Line Definition, have built-in quality control measures that ensure every product is made to the highest standards. Automated inspection tools, such as Automatic Transmission Cooler Line Assembly, are used to verify that each product meets the required specifications, ensuring consistent quality throughout the production process.

3,Enhanced worker safety: The use of automated machines in assembly lines, such as Auto Assembly Line Photos, has significantly improved the safety of workers. Workers are no longer exposed to hazardous environments or heavy machinery as robots handle the majority of tasks, which reduces the risk of injury or accidents.

Automated Automotive Assembly Line:

An automated automotive assembly line, equipped with machines and robotics, ensures accurate, reliable, and efficient production of automobiles by reducing manual labor. Auto Assembly Line Photos show how machines work tirelessly, achieving a higher output rate in a shorter time frame without breaks. Automated Assembly Line Definition highlights the built-in quality control measures to ensure every product is made to the highest standards. Additionally, technology like Automatic Transmission Cooler Line Assembly verifies that each product meets required specifications, ensuring consistent quality throughout the production process. This automated system not only increases production efficiency but also improves worker safety, reducing the risk of injury or accidents as machines do the majority of the tasks.

PARAMETERS:

| Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

| DOF | 6 | |||||

| Driving Mode | AC Servo Driving | |||||

| Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

| RepeatAccuracy | ±0.05mm | |||||

| Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

| Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

| Motion Range(R) | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

| J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

| J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

| J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

| J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

| J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

| Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

| J2 | 130 | 130 | 100 | 149 | 90 | |

| J3 | 130 | 130 | 135 | 130 | 104 | |

| J4 | 270 | 270 | 300 | 215 | 144 | |

| J5 | 170 | 170 | 198 | 251 | 160 | |

| J6 | 455 | 455 | 194 | 365 | 215 | |

| Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

| Voltage | 380V or 220V | |||||

| Frequency | 50Hz or 60Hz | |||||

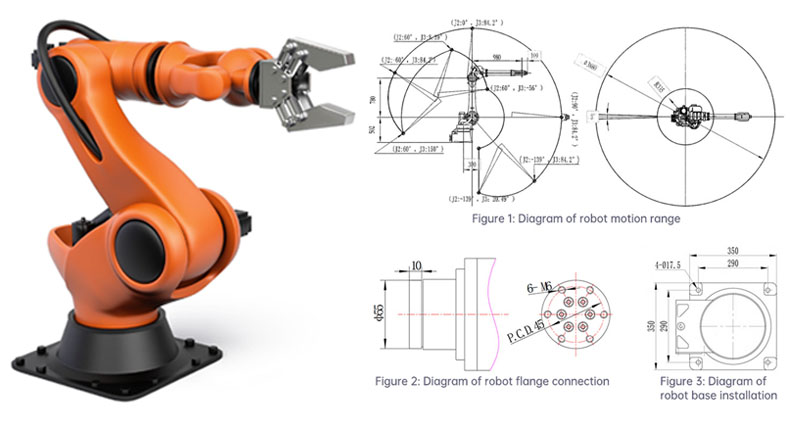

DIMENSIONAL DRAWINGS:

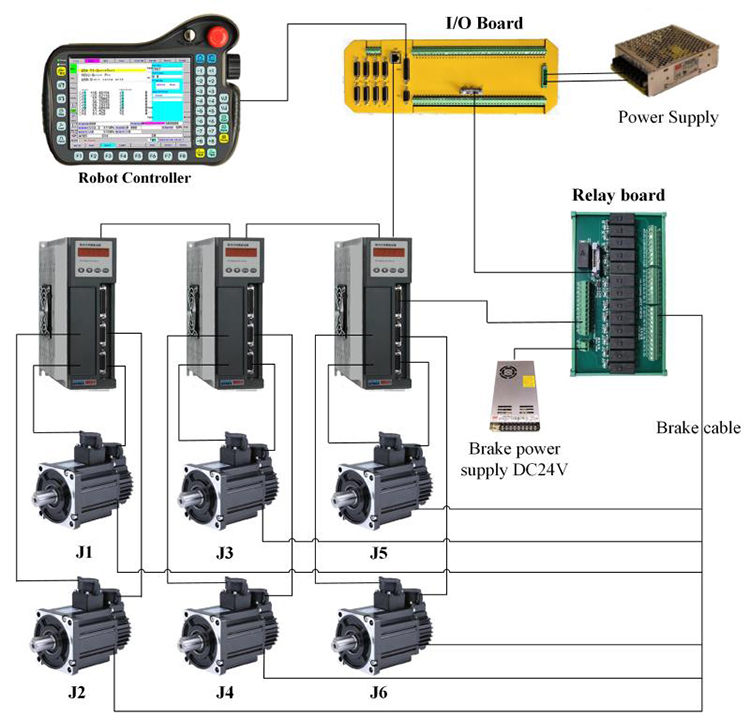

ROBOT CONTROLSYSTEM:

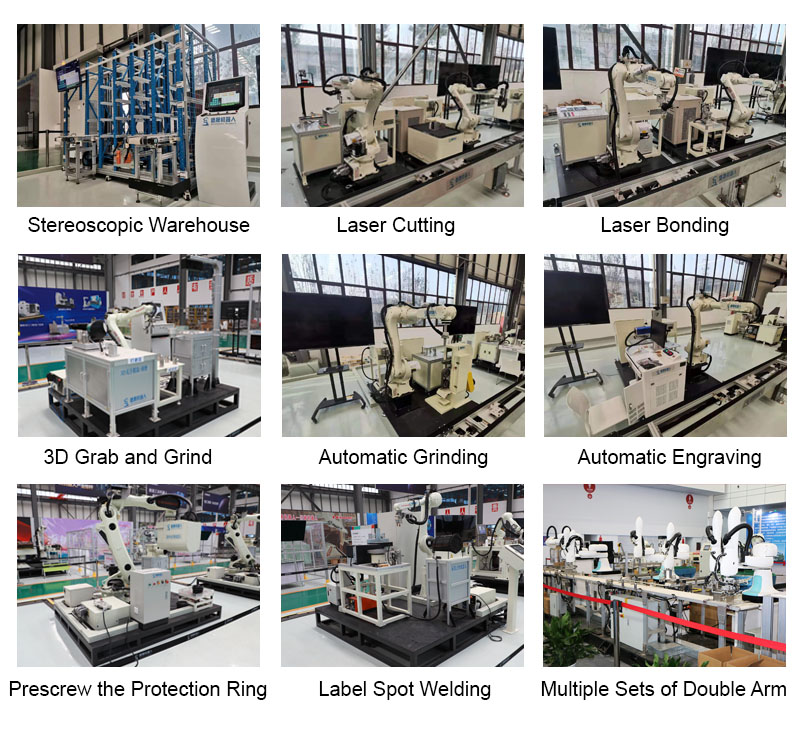

APPLICATIONS:

1,Increased efficiency: Automated automotive assembly lines can significantly increase the production rate of automobiles, leading to improved efficiency. With the use of advanced robotics and automation technology, manufacturing processes can be streamlined and optimized to reduce errors, reduce waste, and enhance productivity.

2,Improved quality control: Automated automotive assembly lines can also improve the overall quality of vehicles produced. Advanced quality control systems can monitor each step of the manufacturing process to ensure that each component meets the necessary standards and specifications. This can help to reduce defects and improve customer satisfaction.

3,Enhanced worker safety: Automated automotive assembly lines can help to create a safer working environment for employees. Robots can perform dangerous or repetitive tasks, reducing the risk of injury or accidents. This can help to improve worker morale and reduce insurance costs for the company.

FEATURES:

1,Precision and accuracy: Automated automotive assembly lines are designed to be highly precise and accurate. Advanced robotics and automation technology can perform tasks with a level of accuracy that is difficult to achieve with manual labor. This can help to reduce errors, improve quality, and increase efficiency.

2,Repetitive tasks: Automated automotive assembly lines are designed to perform repetitive tasks, such as welding, painting, and assembly. This reduces the need for manual labor and can improve productivity and consistency.

3,Integration with manufacturing systems: Automated automotive assembly lines are often integrated with other manufacturing systems, such as inventory management and quality control. This allows for a more streamlined and optimized manufacturing process, reducing waste and improving efficiency. Additionally, automated assembly lines can be easily reconfigured or adapted to meet changing production needs.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US:

| Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

| DOF | 6 | |||||

| Driving Mode | AC Servo Driving | |||||

| Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

| RepeatAccuracy | ±0.05mm | |||||

| Working radius | 1400mm | 1589m m | 1595m m | 1950m m | 2483mm | |

| Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

| Motion Range(R) | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

| J2 | ±120~-8 5 | ±120~-80 | ±132~-9 5 | ±130~-90 | ±80~60 | |

| J3 | ±85~-16 5 | ±85~-16 5 | ±73~-16 3 | ±75~-2 10 | ±80~-190 | |

| J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

| J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

| J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

| Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

| J2 | 130 | 130 | 100 | 149 | 90 | |

| J3 | 130 | 130 | 135 | 130 | 104 | |

| J4 | 270 | 270 | 300 | 215 | 144 | |

| J5 | 170 | 170 | 198 | 251 | 160 | |

| J6 | 455 | 455 | 194 | 365 | 215 | |

| Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

| Voltage | 380V or 220V | |||||

| Frequency | 50Hz or 60Hz | |||||