Articulated Industrial Robot Arm

Advantages of Articulated Industrial Robot Arm:

1,High flexibility: Industrial robot arms can be driven in different directions and angles, with a high range of activity and accuracy, and can even operate in small spaces. This makes them ideal for a variety of applications, including welding tasks such as GTAW (Gas Tungsten Arc Welding), which requires precision and maneuverability in tight spaces.

2,High degree of automation: Industrial robot arms can achieve a highly automated operation process, which can carry out fast and accurate movement, handling, and processing, thereby improving production efficiency and quality. This automation is particularly useful in welding tasks, such as welding oxygen tanks and welding cast steel, as it ensures consistent results, reduces the likelihood of errors, and minimizes the need for human intervention.

3,Strong safety: Industrial robot arms can carry out collaborative operations to reduce the risk of injury at human work, and have a safety control system that can monitor the environment around the robot arm and respond to emergencies to ensure the safety of the workplace, even when used in hazardous tasks like welding. The use of robot arms in welding tasks can help reduce the risk of injuries associated with manual welding, thus promoting safety and reducing the likelihood of human error.

Articulated Industrial Robot Arm:

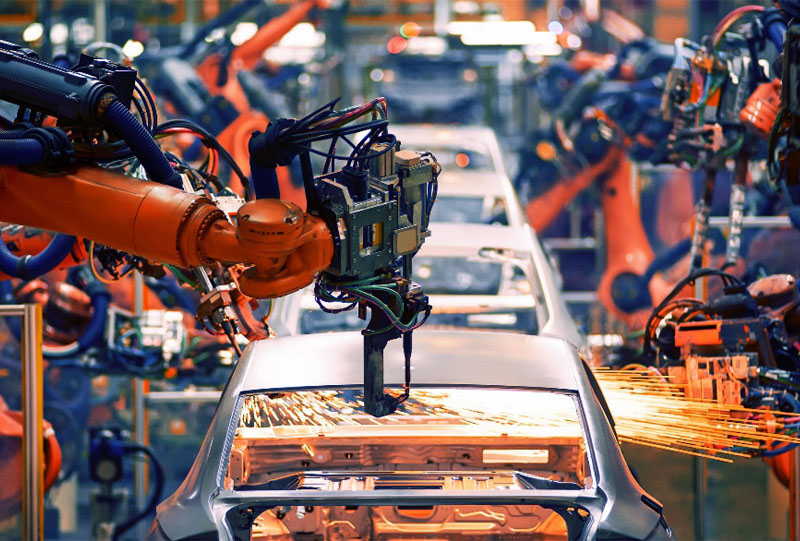

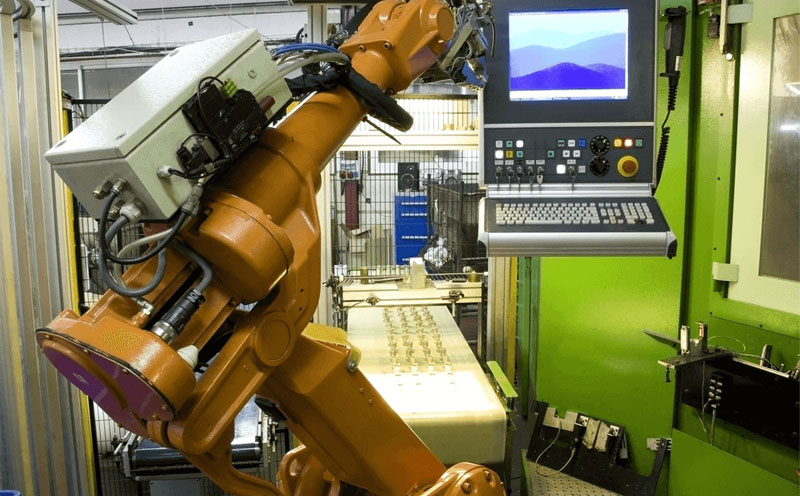

The Articulated Industrial Robot Arm is one of the most innovative pieces of technology used in modern industries. These robot arms are capable of a range of movements, angles, and directions, and can even operate in small spaces. This flexibility makes them particularly useful in welding tasks, such as GTAW (Gas Tungsten Arc Welding), welding oxygen tanks, and welding cast steel.

One of the major advantages of using Articulated Industrial Robot Arms is their high degree of automation. These robot arms can be programmed to carry out precise movement, handling, and processing tasks, thereby improving production efficiency and quality. In welding tasks, automation is especially important as it helps ensure consistent results, reduces the likelihood of errors, and minimizes the need for human intervention.

Safety is another benefit of using Articulated Industrial Robot Arms. They can carry out collaborative operations, working alongside humans to reduce the risk of injuries at work. Additionally, these robot arms have advanced safety control systems that can monitor the environment around them and respond to emergencies, ensuring the safety of the workplace.

In conclusion, the use of Articulated Industrial Robot Arms in welding tasks such as GTAW, welding oxygen tanks, and welding cast steel is highly beneficial to industries. With their flexibility, automation, and safety features, these robot arms can greatly improve production efficiency and quality while reducing the risk of injuries and errors.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

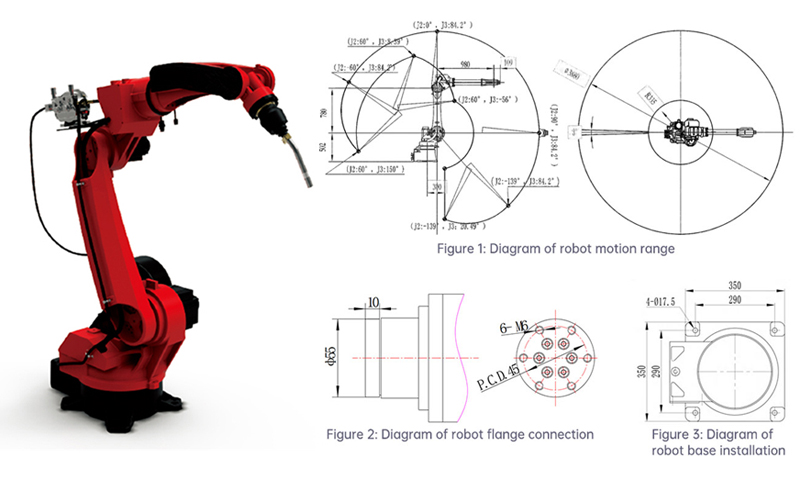

DIMENSIONAL DRAWINGS:

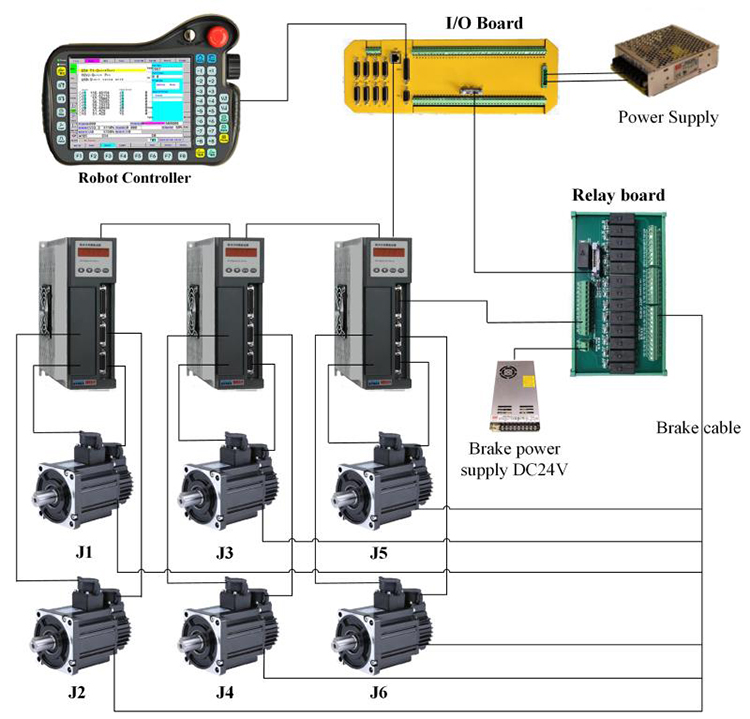

ROBOT CONTROLSYSTEM:

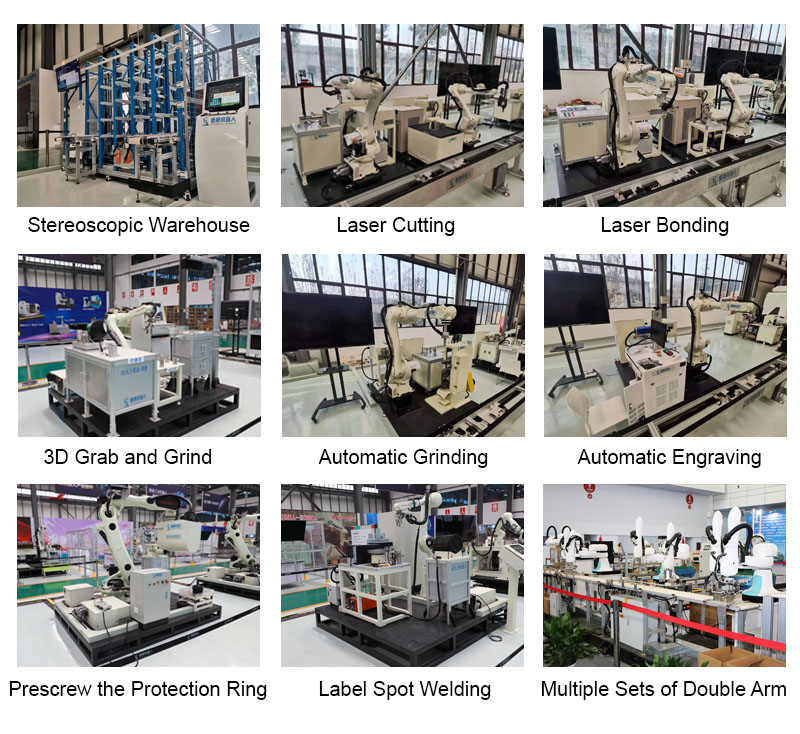

APPLICATIONS:

1,Production: In manufacturing, palletizing robots may be used to stack and move heavy elements, finished merchandise and raw substances. Inside the car industry, for instance, they could location frames, engines, and different important additives to speed up production and boom manufacturing performance.

2,Logistics and warehousing: Inside the logistics and warehousing industry, palletizing robots may be used to bundle, sort and arrange goods. As an example, items can be stacked by using robots and moved to an appropriate area consistent with exclusive orders. This permits logistics agencies and garage centers to manage and pass massive volumes of goods extra effectively and reduce human useful resource costs.

3,Meals and beverage enterprise: Palletizing robots are normally used inside the food and beverage industry to stack and move meals cans, bottles, bins and baggage. The robotic can quickly and efficaciously p.c. Those products into containers or pallets. This automatic technique can lessen the quantity of labor for workers, thereby growing manufacturing performance and lowering human errors.

FEATURES:

1,Excessive precision: palletizing robotic may be operated according to very unique preset parameters, as a result guaranteeing a excessive diploma of accuracy in stacking and arranging goods. the robotic's excessive-precision operation nearly removes stacking troubles caused by human mistakes.

2,Programmable: palletizing robots for cargo stacking are programmable, which means that they are able to customize their manner of operation to fit differing types and sizes of cargo. this makes them extra flexible and able to meet different stacking desires in a spread of industries.

3,High Protection: palletizing robots perform with a excessive degree of protection. via using superior sensor era and tracking systems, the robotic is able to avoid collision with any moving character or other boundaries, consequently ensuring a high stage of protection all through use.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: